Abstract

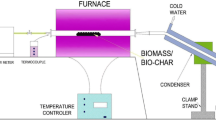

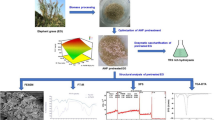

Elephant grass (Pennisetum purpureum Schum.) is one such resource with a great amount of carbohydrate and lignin polymers that together represent high volatile content of biomass suitable for conversion into bio-oil by fast pyrolysis. However, the high ash content inhibits the realization of its full potential as a pyrolysis feedstock as the ash reduces product yields and changes chemical pathway toward undesired product selectivity including oxygenated compounds that are known to result in bio-oil instability. In this study, elephant grass was pretreated prior to pyrolysis using liquid hot water (LHW) and acid solution washing (AW) to explore whether reduction in ash content could improve its physical properties, energy density and pyrolysis products selectivity. Upon characterization of compositional analyses, chemical ash composition by X-ray fluorescence, Fourier-Transform Infrared Spectroscopy and cellulose crystallinity Index (CrI) before and after demineralization treatments we found that washing pretreatment processes were efficient in ash removal increasing HHV and the volatile content, and decreasing fixed carbon and moisture. The use of the pretreated biomass as feedstock for pyrolysis performed at 600 °C in a micro-pyrolyzer 5200 HP-R Py-GC/MS reveals interesting product distribution. While many oxygenated compounds were identified as pyrolysis products for both raw and pretreated elephant grass significant changes were observed in the products of the pretreated biomass, such as an increased yield of levoglucosan (LG) for LHW washed biomass, which presented the lowest CrI, an evidence that cellulose content and its structure influences the pyrolysis product distribution.

Similar content being viewed by others

References

Mohammed IY, Abakr YA, Yusup S, Kazi FK. Valorization of Napier grass via intermediate pyrolysis: optimization using response surface methodology and pyrolysis products characterization. J Clean Prod. 2017;142:1848–66.

Strezov V, Evans TJ, Hayman C. Thermal conversion of elephant grass (Pennisetum Purpureum Schum) to bio-gas, bio-oil and charcoal. Bioresour Technol. 2008;99:8394–9.

Scholl AL, Menegol D, Pitarelo AP, Fontana RC, Filho AZ, Ramos LP, et al. Ethanol production from sugars obtained during enzymatic hydrolysis of elephant grass (Pennisetum purpureum, Schum.) pretreated by steam explosion. Bioresour Technol. 2015;192:228–37.

Tsai WT, Tsai YL. Thermochemical characterization of napier grass as an energy source and its environmental and economic benefit analysis. Energy Sourc B Econ Plan Policy. 2016;11:2.

Cai C, Wang L, Wang G, Hao J, Bai X, Wang Z, et al. Effects of dry explosion pretreatment on physicochemical and fuel properties of hybrid pennisetum (Pennisetum americanum × P. purpureum). Bioresour Technol. 2020;297:122508.

Trevisan H, Rezende CA. Pure, stable and highly antioxidant lignin nanoparticles from elephant grass. Ind Crops Prod. 2020;145:112105.

Collard FX, Blin J, Bensakhria A, Valette J. Influence of impregnated metal on the pyrolysis conversion of biomass constituents. J Anal Appl Pyrolysis. 2012;95:213–26.

Eom IY, Kim JY, Kim TS, Lee SM, Choi D, Choi IG, et al. Effect of essential inorganic metals on primary thermal degradation of lignocellulosic biomass. Bioresour Technol. 2012;104:687–94.

Vassilev SV, Vassileva CG. Water-soluble fractions of biomass and biomass ash and their significance for biofuel application. Energy and fuels. Am Chem Soc 2019; 2763–77.

Mayer ZA, Apfelbacher A, Hornung A. Effect of sample preparation on the thermal degradation of metal-added biomass. J Anal Appl Pyrolysis. 2012;94:170–6.

Gray MR, Corcoran WH, Gavalas GR. Pyrolysis of a wood-derived material. Effects of moisture and ash content. Ind Eng Chem Process Des Dev. 1985;24:646–51.

Serapiglia MJ, Mullen CA, Boateng AA, Cortese LM, Bonos SA, Hoffman L. Evaluation of the impact of compositional differences in switchgrass genotypes on pyrolysis product yield. Ind Crops Prod. 2015;74:957–68.

Junior II, Avelar M, Octavio R, Alves M, Dufour A, Wojcieszak R. Levoglucosan: a promising platform molecule? Royal Soc Chem. 2020;6:580–98.

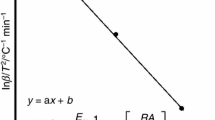

Braga RM, Costa TR, Freitas JCO, Barros JMF, Melo DMA, Melo MAF. Pyrolysis kinetics of elephant grass pretreated biomasses. J Therm Anal Calorim. 2014;117:1341–8.

Van Soest PJ, Wine RH. Use of detergents in the analysis of fibrous feeds. IV. Determination of plant cell-wall constituents. J AOAC Int. 1967

Segal L, Creely JJ, Martin AE, Conrad CM. An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text Res J. 1959

Varhegyi G, Antal MJ, Szekely T, Till F, Jakab E, Varhegyi G. Simultaneous thermogravimetric-mass spectrometric studies of the thermal decomposition of biopolymers. 1. Avicel cellulose in the presence and absence of catalysts. Energy Fuels. 1988; 3:267–272

Braga RM, Melo DMA, Sobrinho EV, Barros JMF, Melo MAF, Carvalho AFM, et al. Catalytic upgrading of Elephant grass (Pennisetum purpureum Schum) pyrolysis vapor using WO3 supported on RHA and RHA-MCM-41. Catal Today [Internet]. 2017;279:224–32. https://linkinghub.elsevier.com/retrieve/pii/S0920586116303935

Hu F, Ragauskas A. Pretreatment and lignocellulosic chemistry Bioenergy Res. 2012;5:1043–66.

Oh SY, Yoo D, Shin Y, Seo G. FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohydr Res. 2005;340:417–28.

Di Blasi C, Branca C, Derrico G. Degradation characteristics of straw and washed straw. Thermochim Acta. 2000;364:133–42.

Chen H, Liu Z, Chen X, Chen Y, Dong Z, Wang X, et al. Bioresource technology comparative pyrolysis behaviors of stalk, wood and shell biomass: correlation of cellulose crystallinity and reaction kinetics. Bioresour Technol. 2020;310:123498. https://doi.org/10.1016/j.biortech.2020.123498.

Shi L, Yu S, Wang FC, Wang J. Pyrolytic characteristics of rice straw and its constituents catalyzed by internal alkali and alkali earth metals. Fuel. 2012;96:586–94.

De Conto D, Silvestre WP, Baldasso C, Godinho M. Performance of rotary kiln reactor for the elephant grass pyrolysis. Bioresour Technol. 2016;218:153–60.

Mohammed IY, Abakr YA, Kazi FK, Yusup S, Alshareef I, Chin SA. Comprehensive characterization of Napier grass as a feedstock for thermochemical conversion. Energies. 2015

Mohanty P, Nanda S, Pant KK, Naik S, Kozinski JA, Dalai AK. Evaluation of the physiochemical development of biochars obtained from pyrolysis of wheat straw, timothy grass and pinewood: effects of heating rate. J Anal Appl Pyrolysis. 2013;104:485–93.

Irfan M, Chen Q, Yue Y, Pang R, Lin Q, Zhao X, et al. Co-production of biochar, bio-oil and syngas from halophyte grass (Achnatherum splendens L.) under three different pyrolysis temperatures. Bioresour Technol. 2016;211:457–63.

Lu Q, Yang XC, Dong CQ, Zhang ZF, Zhang XM, Zhu XF. Influence of pyrolysis temperature and time on the cellulose fast pyrolysis products: analytical Py-GC/MS study. J Anal Appl Pyrolysis. 2011;92:430–8.

Shen D, Jin W, Hu J, Xiao R, Luo K. An overview on fast pyrolysis of the main constituents in lignocellulosic biomass to valued-added chemicals: structures, pathways and interactions. Renew Sustain Energy Rev. 2015;51:761–74.

Yu Y, Wu H. Significant differences in the hydrolysis behavior of amorphous and crystalline portions within microcrystalline cellulose in hot-compressed water. Ind Eng Chem Res. 2010;49:3902–9.

Rizhikovs J, Brazdausks P, Dobele G, Jurkjane V, Paze A, Meile K, et al. Industrial crops and products pretreated hemp shives: possibilities of conversion into levoglucosan and levoglucosenone. Ind Crops Prod. 2019;139:111590.

Zhou X, Nolte MW, Mayes HB, Shanks BH, Broadbelt LJ. Experimental and mechanistic modeling of fast pyrolysis of neat glucose-based carbohydrates. 1. Experiments and development of a detailed mechanistic model. Ind Eng Chem Res. 2014;34:13274–89.

Zhang H, Meng X, Liu C, Wang Y, Xiao R. Selective low-temperature pyrolysis of microcrystalline cellulose to produce levoglucosan and levoglucosenone in a fixed bed reactor. Fuel Process Technol. 2017;167:484–90.

Lindstrom JK, Proano-aviles J, Peterson CA, Stansell JS, Johnston PA, Brown RC. Competing reactions limit levoglucosan yield during fast pyrolysis of cellulose. R Soc Chem. 2019;21:178–86.

Shimada N, Kawamoto H, Saka S. Different action of alkali/alkaline earth metal chlorides on cellulose pyrolysis. J Anal Appl Pyrolysis. 2008;81:80–7.

Patwardhan PR, Satrio JA, Brown RC, Shanks BH. Influence of inorganic salts on the primary pyrolysis products of cellulose. Bioresour Technol. 2010;101:4646–55.

Danon B, Marcotullio G, De Jong W. Mechanistic and kinetic aspects of pentose dehydration towards furfural in aqueous media employing homogeneous catalysis. Green Chem. 2014;16:39–54.

Shen DK, Gu S, Bridgwater AV. Study on the pyrolytic behaviour of xylan-based hemicellulose using TG–FTIR and Py–GC–FTIR. J Anal Appl Pyrolysis. 2010;87:199–206.

Mihalcik DJ, Mullen CA, Boateng AA. Screening acidic zeolites for catalytic fast pyrolysis of biomass and its components. J Anal Appl Pyrolysis. 2011;92:224–32.

Wang Z, Ma R, Song W. Influence of HSAPO-34, HZSM-5, and NaY on pyrolysis of corn straw fermentation residue via Py-GC/MS. J Anal Appl Pyrolysis. 2016;122:183–90.

Acknowledgements

The authors gratefully acknowledge the CNPq for financial support, UFRN/NUPPRAR and LNA from the Federal University of Rio Grande do Norte for compositional and ultimate analysis, LabTam/NUPPRAR/UFRN for facilities and Petrobras for support. USDA-ARS/UFRN NCFA 8072-41000-095-24 is hereby acknowledged.

Funding

This work was supported by The National Council for Scientific and Technological Development (CNPq).

Author information

Authors and Affiliations

Contributions

Renata Martins Braga was involved in methodology, investigation, formal analysis, data curation, investigation and writing—original draft; Julio C. O. Freitas contributed to formal analysis, review and editing; Dulce M. A. Melo was involved in resources, review and editing; Marcus A. F. Melo contributed to acquisition and supervision; Akwasi A. Boateng was involved in review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Braga, R.M., Melo, D.M.A., Melo, M.A.F. et al. Effect of pretreatment on pyrolysis products of Pennisetum purpureum Schum. by Py-GC/MS. J Therm Anal Calorim 147, 6655–6663 (2022). https://doi.org/10.1007/s10973-021-11025-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11025-5