Abstract

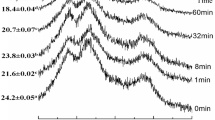

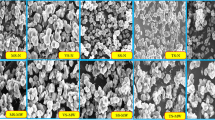

Rice (Oryza sativa L.) is a cereal of great economic and nutritional importance due to its expressive consumption. To achieve new properties or improve the characteristics presented by native starch, modifications are carried out, catching the attention of many researchers. Therefore, this study aimed to analyse the effects of ultrasound on the thermal, structural and morphological properties of organic rice starch. The starch was extracted by the aqueous method, followed by alcalase treatment for protein removal. Colourimetry, thermogravimetry, differential scanning calorimetry, X-ray powder diffractometry and microscopy were analysed. After treatment of the native starch with the alcalase, a reduction in the thermal stability temperature was observed, as well as a reduction in the gelatinisation transition temperatures and an increase in the gelatinisation enthalpy. When modified by ultrasound, under greater amplitude of vibration, shorter time and lower concentration, an increase in the thermal stability of the starch was achieved. In addition, an increase in peak temperature (Tp) was observed and there was no significant difference for enthalpy in most treatments. The concentration influenced the gelatinisation enthalpy (ΔHgel) only of the treatments under the lowest amplitude of vibration (75%). Changes in relative crystallinity were also found. Through microscopy, it was identified that the alcalase treatment was efficient because no proteins were observed in the images. The use of the physically modified organic rice starch may be an alternative for use as an excipient in the pharmaceutical industry and encapsulating agent in the food industry.

Similar content being viewed by others

References

Agostinetto D, Fleck NG, Rizzardi MA, Junior AM, Vidal RA. Arroz vermelho: ecofisiologia e estratégias de controle. Cienc Rural. 2001;31:341–9.

Walter M, Marchezan E, Avila LA. Arroz: composição e características nutricionais. Cienc Rural. 2008;38:1184–92.

Kong S, Lee J. Antioxidants in milling fractions of black rice cultivars. Food Chem. 2010;120:278–81.

Conry MJ. Comparisons of early, normal and late sowing at three rates of nitrogen on the yield, grain nitrogen and screening contents of Blenheim spring malting barley in Ireland. J Agric Sci. 1995;125:183–8.

Andreson GKS, Rundlof M, Smith HG. Organic farming improves pollination success in strawberries. PLoS ONE. 2012;7(2):e31599.

Zhou Z, Robards K, Helliwell S, Blanchard C. Composition and functional properties of rice. Int J Food Sci Technol. 2002;37:849–68.

de Souza D, Sbardelotto AF, Ziegler DR, Marczak LDF, Tessaro IC. Characterization of rice starch and protein obtained by a fast alkaline extraction method. Food Chem. 2016;191:36–44.

Park EY, Kim H, Kim J, Lim S. Pasting properties of potato starch and waxy maize starch mixtures. Starch-Stärke. 2009;61:352–7.

Zavareze ER, Dias ARG. Impact of heat-moisture treatment and annealing in starches: A review. Carbohydr Polym. 2011;83:317–28.

Kaur M, Kaur N, Kaur M, Sandhu KS. Some properties of rice grains, flour and starches: A comparison of organic and conventional modes of farming. LWT Food Sci Technol. 2015;61:152–7.

Dalzochio MS, Baldin R, Stenert C, Maltchik L. Can organic and conventional agricultural systems affect wetland macroinvertebrate taxa in rice fields? Basic Appl Ecol. 2016;17:220–9.

Hagenimana A, Ding X, Fang T. Evaluation of rice flour modified by extrusion cooking. J Cereal Sci. 2006;43:38–46.

Kadan RS, Bryant RJ, Pepperman AB. Functional properties of extruded rice flours. J Food Sci. 2003;68:1669–72.

Anderson AK, Guraya HS, James C, Salvaggio L. Digestibility and pasting properties of rice starch heat-moisture treated at the melting temperature (Tm). Starch-Stärke. 2002;54:401–9.

Shih FF, King J, Daigle K, An HJ, Ali R. Physicochemical properties of rice starch modified by hydrothermal treatments. Cereal Chem. 2007;84:527–31.

Devi AF, Fibrianto K, Torley PJ, Bhandari B. Physical properties of cryomilled rice starch. J Cereal Sci. 2009;49:278–84.

Chung KM, Moon TW, Kim H, Chun JK. Physicochemical properties of sonicated mung bean, potato and rice starches. Cereal Chem. 2002;79:631–3.

Bao J, Corke H. Pasting properties of γ-irradiated rice starches as affected by pH. J Agric Food Chem. 2002;50:336–41.

Wu D, Shu Q, Wang Z, Xia Y. Effect of gamma irradiation on starch viscosity and physicochemical properties of different rice. Radiat Phys Chem. 2002;65:79–86.

Wang L, Wang YJ. Rice starch isolation by neutral protease and high-intensity ultrasound. J Cereal Sci. 2004;39:291–6.

Chemat F, Huma Z, Muhammed KK. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason Sonochem. 2011;18:813–35.

Bet CD, Oliveira CS de, Colman TAD, Bisinella RZB, Beninca C, Lacerda LG, Ramos AP, Schnitzler E. Aqueous extraction of organic amaranth starch and their by-products. J Therm Anal Calorim. 2019;1–17.

Garcia R, Bello Pérez LA, Aguirre Cruz A, Saguilán AA, Torres HJ, Ramirez AJ. Effect of ultrasonic treatment on the morphological, physicochemical, functional, and rheological properties of starches with different granule size. Starch-Stärke. 2016;68:1–8.

Hornung PS, Ávila S, Lazzarotto M, Lazzarotto SRS, Siqueira GLA, Schnitzler E, Ribani RH. Enhancement of the functional properties of Dioscoreaceas native starches: Mixture as a green modification process. Thermochim Acta. 2017;649:31–40.

Andrade MMP, Oliveira CS, Colman TAD, Costa FJOG, Schnitzler E. Effects of heat–moisture treatment on organic cassava starch thermal, rheological and structural study. J Therm Anal Calorim. 2014;115:2115–22.

Bet CD, Cordoba LP, Ribeiro LS, Schnitlzer E. Common vetch (Vicia sativa) as a new starch source: Its thermal, rheological and structural properties after acid hydrolysis. Food Biophys. 2016;11:275–82.

Bet CD, Oliveira CS, Colman TAD, Marinho MT, Lacerda LG, Ramos AP, Schnitzler E. Organic amaranth starch: A study of its technological properties after heat-moisture treatment. Food Chem. 2018;264:435–42.

Oliveira CS, Bet CD, Bisinella RZB, Waiga LH, Colman TAD, Schnitzler E. Heat-moisture (HMT) on blends from potato starch (OS) and sweet potato starch (SPS). J Therm Anal Calorim. 2018;133:1491–8.

Colman TAD, Demiate IM, Schnitzler E. The effect of microwave radiation on some thermal, rheological and structural properties of cassava starch. J Therm Anal Calorim. 2014;115:2245–52.

Beninca C, Barboza RA, Oliveira CS, Bet CD, Bisinella RZB, Schnitzler E. Corn and pinhão starches modified with sodium tripolyphosphate: thermal, pasting. Struct Morphol Prop Starch-Stärke. 2019;71:1–8.

Ziegler V, Ferreira CD, Goebel JT, El Halal SL, Santetti GS, Gutkoski LC, Zavareze Eda R, Elias MC. Changes in properties of starch isolated from whole rice grains with brown, black, and red pericarp after storage at different temperatures. Food Chem. 2017;216:194–200.

Ionashiro M, Caires FJ, Gome DJCG. Fundamentos da termogravimetria e análise térmica diferencial/calorimetria exploratória diferencial. 2nd ed. São Paulo: Giz Editorial; 2014.

Chandra IK, Kasim NS, Nguyen PLT, Tran-Thi NY, Ismadji S, Ju YH. Physicochemical characterization of starch isolated from red Monascus rice. J Chem Eng. 2014;9:527–34.

Ito VC, Schnitzler E, Demiate IM, Eusébio MES, Lacerda LG, Castro RAE. Physicochemical, thermal, crystallographic, and morphological properties of biodynamic black rice starch, and of residual fractions from aqueous extraction. Starch/Stärke. 2018;1–7.

Lacerda LG, Colman TAD, Bauab T, Filho MASC, Demiate IM, Vasconcelos EC, Schnitzler E. Thermal, structural and rheological properties of starch from avocado seeds (Persea americana, Miller) modified with standard sodium hypochlorite solutions. J Therm Anal Calorim. 2013;115:1893–9.

Li Y, Shoemaker CF, Shen X, Ma J, Ibáñez-Carranza AM, Zhong F. The isolation of rice starch with food grade proteases combined with other treatments. Food Sci Technol Int. 2008;14:215–24.

Serrano PO, Franco CML. Annealing and enzymatic hydrolysis of cassava starch. Braz J Food Technol. 2005;8:220–32.

Sin LT, Rahman WAR, Rahman AR, Mokhtar M. Determination of thermal stability and activation energy of polyvinyl alcohol–cassava starch blends. Carbohyd Polym. 2011;83:303–5.

Singh N, Singh J, Kaur L, Sodhi NS, Gill BS. Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 2003;81:219–31.

Amagliani L, O’Regan J, Kelly AL, O’Mahony JA. Chemistry, structure, functionality and applications of rice starch. J Cereal Sci. 2016;70:291–300.

Li Y, Shoemaker CF, Ma J, Luo C, Zhong F. Effects of Alcalase/Protease N treatments on rice starch isolation and their effects on its properties. Food Chem. 2009;114:821–8.

Jayakody L, Hoover R. Effect of annealing on the molecular structure and physicochemical properties of starches from different botanical origins-A review. Carbohyd Polym. 2008;74:691–703.

Lin JH, Wang SW, Chang YH. Effect of molecular size on gelatinization thermal properties before and after annealing of rice starch with different amylose contents. Food Hydrocoll. 2008;22:156–63.

Lacerda LG, Silva Carvalho MAS, Demiate IM, Bannach G, Ionashiro M, Schnitzler E. Thermal behaviour of corn starch granules under action of fungal α-amylase. J Therm Anal Calorim. 2008;3:445–9.

Park D, Han J. Quality controlling of brown rice by ultrasound treatment and its effect on isolated starch. Carbohyd Polym. 2016;137:30–8.

Bao J, Bergman CJ. The functionality of rice starch. In: Eliasson AC, editor. Starch in Food: Structure, Function and Applications. Cambridge: Woodhead Publishing; 2004. p. 258–94.

Fitzgerald M. Starch. In: Champagne ET, editor. Rice: Chemistry and Technology. US: American Association of Cereal Chemists; 2004. p. 109–41.

Zhu F. Impact of ultrasound on structure, physicochemical properties, modifications, and applications of starch. Trends Food Sci Technol. 2015;43:1–17.

AOAC. Association of official analytical chemists. Official methods of analysis of AOAC international. 18th ed. Gaithersburg; 2011.

Acknowledgements

The authors gratefully acknowledge the financial resources provided by CAPES (Coordination for Higher Education Staff Development) and CNPq (Proc. No 307654/2017-6), Brazil.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bisinella, R.Z.B., Beninca, C., Bet, C.D. et al. Thermal, structural and morphological characterisation of organic rice starch after physical treatment. J Therm Anal Calorim 147, 3615–3623 (2022). https://doi.org/10.1007/s10973-021-10712-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10712-7