Abstract

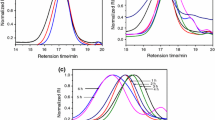

Efficient incorporation of polar monomers in polyolefin can lead to many desirable properties in the parent chain. Herein, we report the synthesis of ethylene and methyl methacrylate (MMA)-based copolymers by transition metal-catalysed reverse atom transfer radical polymerization technique with controlled ethylene feed pressure. Successful copolymerization was confirmed by 1H nuclear magnetic resonance analysis. With increasing polymerization time, resultant copolymers exhibit bimodal molecular weight distributions with controlled high molecular weight component and less-controlled low molecular weight component as confirmed by size-exclusion chromatography analysis. Morphological and crystal structures of the copolymer were established using scanning electron microscope and X-ray diffraction analysis, respectively. Thermogravimetric analysis of the copolymer under non-isothermal condition shows a two-step decomposition process with the major decomposition in the range of 320–450 °C. Based on approaches of Friedman and Flynn–Wall–Ozawa, model-free multivariate nonlinear regression analyses were performed to find out the formal mechanisms, kinetic model and its corresponding kinetic triplets. The results revealed the nth-order (Fn) mechanism responsible for the decomposition of the copolymer. The estimated kinetic parameters for the decomposition of poly(MMA-co-ethylene) copolymer were Ea= 227.80 kJ mol−1 and A = 6.76 × 1015 s−1.

Similar content being viewed by others

References

Ziegler K, Holzkamp E, Breil H, Martin H. Polymerization of ethylene and other olefins. Angew Chem. 1955;67:426.

Natta G, Pasquon I. The kinetics of the stereospecific polymerization of α-olefins. Adv Catal. 1959;11:1–66.

Sedláček T. Processing techniques for polyolefins. In: Al-Ali AlMa’adeed M, Krupa I, editors. Polyolefin compounds and materials. Springer series on polymer and composite materials. Basel: Springer; 2016. p. 79.

Boffa LS, Novak BM. Copolymerization of polar monomers with olefins using transition metal complexes. Chem Rev. 2000;100:1479–93.

Kermagoret A, Debuigne A, Jerome C, Detrembleur C. Precision design of ethylene-polar-monomer-based copolymers by organometallic mediated radical polymerization. Nat Chem. 2014;6:179–87.

Sugimoto R, Kaneko H, Saito J, Kawahara N, Matsuo S, Matsugi T. Controlled radical polymerization with polyolefin macroinitiator: a convenient and versatile approach to polyolefin based block and graft copolymers. Polym Bull. 2014;71:1421–31.

Franssen NMG, Reek JNH, de Bruin B. Synthesis of functional ‘‘polyolefins’’: state of the art and remaining challenges. Chem Soc Rev. 2013;42:5809–32.

Kato M, Kamigaito M, Sawamoto M, Higashimura T. Polymerization of methyl methacrylate with the carbon tetrachloride/dichlorotris-(triphenylphosphine) ruthenium (II)/methylaluminum bis(2,6-di-tert-butylphenoxide) initiating system: possibility of living radical polymerization. Macromolecules. 1995;28:1721–3.

Nicolay R, Kwak Y, Matyjaszewski K. Dibromotrithiocarbonate iniferter for concurrent ATRP and RAFT polymerization. Effect of monomer, catalyst, and chain transfer agent structure on the polymerization mechanism. Macromolecules. 2008;41:4585–96.

Matyjaszewski K. Transition metal catalysis in controlled radical polymerization: atom transfer radical polymerization. Chem Eur J. 1999;5:3095–102.

Mori H, Muller AHE. New polymeric architectures with (meth)acrylic acid segments. Prog Polym Sci. 2003;28:1403–39.

Saikia PJ, Baruah SD. Controlled radical polymerization of n-hexadecyl methacrylate mediated by tris(2,2′- bipyridine)iron(III) complexes. Polym Bull. 2013;70:3291–303.

Saikia PJ, Hazarika AK, Baruah SD. Iron(III)-mediated ATRP systems of n-docosyl acrylate with AIBN and BPO. Polym Bull. 2013;70:1483–98.

Gromada J, Matyjaszewski K. Simultaneous reverse and normal initiation in atom transfer radical polymerization. Macromolecules. 2001;34:7664–71.

Geroges MK, Veregin RPN, Kazmaier PM, Hamer GK. Narrow molecular weight resins by a free-radical polymerization process. Macromolecules. 1993;26:2987–8.

Elsen AM, Nicolay R, Matyjaszewski K. Dual concurrent ATRP/RAFT of methyl acrylate co-initiated by alkyl halides. Macromolecules. 2011;44:1752–4.

Zhang G, Song IY, Park T, Choi W. Recyclable and stable ruthenium catalyst for free radical polymerization at ambient temperature initiated by visible light photocatalysis. Green Chem. 2012;14:618–21.

Yamago S. Precision polymer synthesis by degenerative transfer controlled/living radical polymerization using organotellurium, organostibine, and organobismuthine chain-transfer agents. Chem Rev. 2009;109:5051–68.

Ma H, Davis RH, Bowman CN. A novel sequential photoinduced living graft polymerization. Macromolecules. 2000;33:331–5.

Saikia PJ, Goswami A, Baruah SD. Transition metal-catalyzed atom transfer radical polymerization of stearyl methacrylate in the presence of carbon tetrabromide and a conventional radical initiator. J App Polym Sci. 2002;86:386–94.

Saikia PJ, Goswami A, Baruah SD. Reverse atom transfer radical polymerization of stearyl methacrylate using 2,2′-azobisisobutyronitrile as the initiator. J App Polym Sci. 2002;85:1236–45.

Wang JS, Matyjaszewski K. “Living”/controlled radical polymerization. Transition-metal-catalyzed atom transfer radical polymerization in the presence of a conventional radical initiator. Macromolecules. 1995;28:7572–3.

Zhu S, Wang W, Tu W, Yan D. Reverse atom transfer radical polymerization of styrene using BPO as the initiator under heterogeneous conditions. Acta Polym. 1999;50:267–9.

Wang W, Yan D, Jiang X, Detrembleur C, Lecomte P, Jérôme R. Reverse atom-transfer radical polymerization at room temperature. Macromol Rapid Commun. 2001;22:439–43.

Xia J, Matyjaszewski K. Homogeneous reverse atom transfer radical polymerization of styrene initiated by peroxides. Macromolecules. 1999;32:5199–202.

Tao W, Akita S, Nakano R, Ito S, Hoshimoto Y, Ogoshi S, Nozaki K. Copolymerisation of ethylene with polar monomers by using palladium catalysts bearing an N-heterocyclic carbene–phosphine oxide bidentate ligand. Chem Commun. 2017;53:2630–3.

Zhai F, Solomon JB, Jordan RF. Copolymerization of ethylene with acrylate monomers by amide-functionalized α-diimine Pd catalysts. Organometallics. 2017;36:1873–9.

Carrow BP, Nozaki K. Transition metal catalyzed functional polyolefin synthesis: effecting control through chelating ancillary ligand design and mechanistic insights. Macromolecules. 2014;47:2541–55.

Nakano R, Chung LW, Watanabe Y, Okuno Y, Okumura Y, Ito S, Morokuma K, Nozaki K. Elucidating the key role of phosphine–sulfonate ligands in palladium-catalyzed ethylene polymerization: effect of ligand structure on the molecular weight and linearity of polyethylene. ACS Catal. 2016;6:6101–13.

Mitsushige Y, Carrow BP, Ito S, Nozaki K. Ligand-controlled insertion regioselectivity accelerates copolymerisation of ethylene with methyl acrylate by cationic bisphosphine monoxide–palladium catalysts. Chem Sci. 2015;7:737–44.

Sui X, Dai S, Chen C. Ethylene polymerization and copolymerization with polar monomers by cationic phosphine phosphonic amide palladium complexes. ACS Catal. 2015;5:5932–7.

Guo L, Dai S, Sui X, Chen C. Palladium and nickel catalyzed chain walking olefin polymerization and copolymerization. ACS Catal. 2016;6:428–41.

Bon SAF, Steward AG, Haddleton DM. Modification of the ω-bromo end group of poly(methacrylate)s prepared by copper(I)-mediated living radical polymerization. J Polym Sci Part A: Polym Chem. 2000;38:2678–86.

Liu S, Elyashiv S, Sen A. Copper-mediated controlled copolymerization of methyl acrylate with 1-alkenes under mild conditions. J Am Chem Soc. 2001;123:12738–9.

Venkatesh R, Klumperman B. Olefin copolymerization via controlled radical polymerization: copolymerization of methyl methacrylate and 1-octene. Macromolecules. 2004;37:1226–33.

Venkatesh R, Harrisson S, Haddleton DM, Klumperman B. Olefin copolymerization via controlled radical polymerization: copolymerization of acrylate and 1-octene. Macromolecules. 2004;37:4406–16.

Tanaka K, Matyjaszewski K. Controlled copolymerization of n-butyl acrylate with nonpolar 1-alkenes using activators regenerated by electron transfer for atom-transfer radical polymerization. Macromolecules. 2007;40:5255–60.

Dommanget C, D’Agosto F, Monteil V. Polymerization of ethylene through reversible addition–fragmentation chain transfer (RAFT). Angew Chem Int Ed. 2014;53:6683–6.

Saikia M, Borphukan S, Baruah U, Gautam A, Saikia PJ, Baruah SD. Poly(ethylene-co-BMA) via dual concurrent ATRP–RAFT and its thermokinetic study. J Therm Anal Calorim. 2017;131:1517–26.

Saikia M, Baruah U, Borphukan S, Saikia BK, Saikia PJ, Baruah SD. Controlled copolymerization of 1-octene and butyl methacrylate via RAFT and their nonisothermal model-free thermokinetic decomposition study. J Polym Sci Part A: Polym Chem. 2019;57:2093–103.

Benarbia A, Elidrissi A, Ganetri I, Touzani R. Synthesis, characterization and thermal degradation kinetics of copolyesters. J Mater Environ Sci. 2014;5:1262–79.

Malek J, Criado JM. A simple method of kinetic-model discrimination, analysis of differential nonisothermal data. Thermochim Acta. 1994;236:187–97.

Atkins P, Paula J. Physical chemistry; Chapter 18. 9th ed. New York: WH Freeman; 2010.

Brown ME. Introduction to thermal analysis; Chapter 3. 2nd ed. Dordrecht: Kluwer; 2001.

Fotso Talla AS, Erchiqui F, Godard F, Kocaefe D. An evaluation of the thermal degradation kinetics of novel melt processed PET–hemp fiber composites. J Therm Anal Calorim. 2016;126:1387–96.

Baruah U, Saikia M, Assanvo EF, Borphukan S, Phukan L, Gautam A, Baruah SD. Synthesis and thermal analysis of poly(methylmethacrylate) oligomer functionalized polyethylene block copolymer. Polym Bull. 2017;74:2137–58.

Das T, Baruah BP, Saikia BK. Thermal behaviour of low-rank Indian coal fines agglomerated with an organic binder. J Therm Anal Calorim. 2016;126:435–46.

Avella M, Avolio R, Bonadies I, Carfagna C. Effect of compatibilization on thermal degradation kinetics of HDPE-based composites containing cellulose reinforcements. J Therm Anal Calorim. 2010;102:975–82.

Zhu F, Feng Q, Xu Y, Liu R, Li K. Kinetics of pyrolysis of ramie fabric wastes from thermogravimetric data. J Therm Anal Calorim. 2015;119:651–7.

Friedman H. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci (Part C): Polym Symp. 1964;6:183–95.

Mothe CG, de Miranda IC. Study of kinetic parameters of thermal decomposition of bagasse and sugarcane straw using Friedman and Ozawa–Flynn–Wall isoconversional methods. J Therm Anal Calorim. 2013;113:497–505.

Cui HW, Jiu JT, Sugahara T, Nagao S, Suganuma K, Uchida H, Schroder KT. Using the Friedman method to study the thermal degradation kinetics of photonically cured electrically conductive adhesives. J Therm Anal Calorim. 2015;119:425–33.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc. 1965;38:1881–6.

Flynn JH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci Part C: Polym Lett. 1966;4:323–8.

Buback M, Dietzsch H. High-pressure free radical copolymerization of ethene and methyl methacrylate. Macromol Chem Phys. 2001;202:1173–81.

Kawahara N, Kojoh S, Matsuo S, Kaneko H, Matsugi T, Saito J, Kashiwa N. Synthetic method of polyethylenepoly(methylmethacrylate) (PE-PMMA) polymer hybrid via reversible addition-fragmentation chain transfer (RAFT) polymerization with functionalized polyethylene. Polym Bull. 2006;57:805–12.

Bakhshi H, Zohuriaan-Mehr MJ, Bouhendi H, Kabiri K. Spectral and chemical determination of copolymer composition of poly (butyl acrylate-co-glycidyl methacrylate) from emulsion polymerization. Polym Test. 2009;28:730–6.

Kook JW, Kim Y, Hwang K, Kim JH, Lee JY. Synthesis of poly(methyl methacrylate-co-butyl acrylate)/perfluorosilyl methacrylate core-shell nanoparticles: novel approach for optimization of coating process. Polymers. 2018;10:1186–99.

Silverstein RM, Blasser GC, Morril TC. Spectrometric identification of organic compounds. 5th ed. Singapore: Wiley; 1991. p. 103–20.

Yaghini N, Iedema PD. Molecular weight and branching distribution modeling in radical polymerization with transfer to polymer and scission under gel conditions and allowing for multiradicals. Macromolecules. 2014;47:4851–63.

Postma A, Davis TP, Li G, Moad G, O’Shea MS. RAFT polymerization with phthalimidomethyl trithiocarbonates or xanthates. On the origin of bimodal molecular weight distributions in living radical polymerization. Macromolecules. 2006;39:5307–18.

Lenzi MK, Cunningham MF, Lima EL, Pinto JC. Producing bimodal molecular weight distribution polymer resins using living and conventional free-radical polymerization. Ind Eng Chem Res. 2005;44:2568–78.

Yang J, Karahalis GJ, Hagadorn JR, Boller TM, Morris EJ, Brant P. Catalysts that produce polyethylene with broad, bimodal molecular weight distribution. WIPO Patent. 2019; WO2019108408.

Yan F, Texter J. Capturing nanoscopic length scales and structures by polymerization in microemulsions. Soft Matter. 2006;2:109–18.

Tehrani-Bagha AR. Waterproof breathable layers—a review. Adv Colloid Interfac Sci. 2019;268:114–35.

Kashiwagi T, Inabi A, Brown JE, Hatada K, Kitayama T, Masuda E. Effects of weak linkages on the thermal and oxidative degradation of poly(methyl methacrylates). Macromolecules. 1986;19:2160–8.

Manring LE. Thermal degradation of poly(methyl methacrylate): random side-group scission. Macromolecules. 1991;24:3304–9.

Holland BJ, Hay JN. The kinetics and mechanisms of the thermal degradation of poly(methyl methacrylate) studied by thermal analysis-Fourier transform infrared spectroscopy. Polymer. 2001;42:4825–35.

Gałka P, Kowalonek J, Kaczmarek H. Thermogravimetric analysis of thermal stability of poly(methyl methacrylate) films modified with photoinitiators. J Therm Anal Calorim. 2014;115:1387–94.

Saikia M, Baruah U, Borphukan S, Saikia PJ, Gautam A, Baruah SD. RAFT mediated miniemulsion copolymerization of ethylene and BMA and their non-isothermal model-free kinetic analysis. Polym Bull. 2019;76:6437–58.

Guo J, Choi KY, Schorck FJ. Miniemulsion copolymerization of ethylene and vinyl acetate. Macromol React Eng. 2009;3:412–8.

Kayacan I, Dogan OM. Pyrolysis of low and high-density polyethylene. Part I: non-isothermal pyrolysis kinetics. Energy Sources Part A Recovery Util Environ Eff. 2008;30:385–91.

Yazdimamaghani M, Pourvala T, Motamedi E, Fathi B, Vashaee D, Tayebi L. Synthesis and characterization of encapsulated nanosilica particles with an acrylic copolymer by in situ emulsion polymerization using thermoresponsive nonionic surfactant. Materials. 2013;6:3727–41.

Biros J, Larina T, Trekoval J, Pouchly J. Dependence of the glass transition temperature of poly (methyl methacrylates) on their tacticity. Colloid Polym Sci. 1982;260:27–30.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;40:53–68.

Skrdla PJ. Dispersive kinetic models predict variation of the activation energy with extent of conversion observed experimentally in isoconversional data. Thermochim Acta. 2014;578:68–73.

Opfermann J. Kinetic analysis using multivariate non-linear regression. I. Basic concepts. J Therm Anal Calorim. 2000;60:641–58.

Budrugeac P. Application of model-free and multivariate non-linear regression methods for evaluation of the thermo-oxidative endurance of a recent manufactured parchment. J Therm Anal Calorim. 2009;97:443–5.

Jankovic B, Mentus A, Jankovic M. A kinetic study of the thermal decomposition process of potassium metabisulfite: estimation of distributed reactivity model. J Phy Chem Solids. 2008;69:1923–33.

Czech Z, Pełech R, Zych K, Swiderska J. Thermal degradation of copolymers based on selected alkyl methacrylates. J Therm Anal Calorim. 2012;109:573–6.

Peterson JD, Vyazovkin S, Wight CA. Kinetic study of stabilizing effect of oxygen on thermal degradation of poly(methyl methacrylate). J Phys Chem. 1999;103:8087–92.

Kang BS, Kim SG, Kim JS. Thermal degradation of poly(methyl methacrylate) polymers: kinetics and recovery of monomers using a fluidized bed reactor. Anal Appl Pyrolysis. 2008;81:7–13.

Jain AA, Mehra A, Ranade VV. Processing of TGA data: analysis of isoconversional and model fitting methods. Fuel. 2016;165:490–8.

Venkatesh M, Ravi P, Tewari SP. Isoconversional kinetic analysis of decomposition of nitroimidazoles: Friedman method vs Flynn–Wall–Ozawa method. J Chem Phys. 2013;117:10162–9.

Gao Z, Kaneko T, Hou D, Nakada M. Kinetics of thermal degradation of poly(methyl methacrylate) studied with the assistance of the fractional conversion at the maximum reaction rate. Polym Degrad Stab. 2004;84:399–403.

Peterson JD, Vyazovkin S, Wigh CA. Kinetics of the thermal and thermo-oxidative degradation of polystyrene, polyethylene and poly(propylene). Macromol Chem Phys. 2001;202:775–84.

Vyazovkin S. Modification of the integral isoconversional method to account for variation in the activation energy. J Comput Chem. 2001;22:178–83.

Vyazovkin S, Sbirrazzuoli N. Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Commun. 2006;27:1515–32.

Budrugeac P. Thermokinetic study of the thermo-oxidative degradation of a composite epoxy resin material. Rev Roum Chim. 2013;58:371–9.

Budrugeac P. Kinetics of the complex process of thermo-oxidative degradation of poly(vinyl alcohol). J Therm Anal Calorim. 2008;92:291–6.

Acknowledgements

The authors wish to thank the Director, CSIR-North East Institute of Science & Technology, Jorhat for his permission to publish the results and CSIR for financial support from CSIR-Network Project CSC-0206. UB also wish to thank CSIR for award of CSIR-Senior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Baruah, U., Borphukan, S., Saikia, M. et al. Non-isothermal decomposition kinetics of in-chain functionalized poly(MMA-co-ethylene). J Therm Anal Calorim 143, 3093–3105 (2021). https://doi.org/10.1007/s10973-020-09464-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09464-7