Abstract

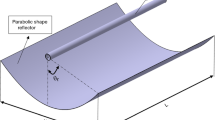

In this study, the thermal and flow characteristics of a parabolic-trough solar collector have been numerically investigated. The turbulent flow inside the receiver tube was modeled via the finite volume method, while a non-uniform concentrated heat flux was imposed on the absorber tube. A Cu–water nanofluid was specified as the heat transfer fluid. The results showed that increasing the Cu nanoparticle concentration led to an increase in the Nusselt number (Nu). Furthermore, the effect of Cu nanoparticle addition on the heat transfer enhancement became more significant as the Reynolds number decreased. This was because nanoparticle addition mainly improved the heat transfer via conduction. As the Reynolds number increased, the role of forced convection overcame that of conduction. Furthermore, it was shown that although Cu nanoparticle addition increased the thermal efficiency, it also increased the pressure drop slightly. The effect of direct normal irradiance changes on the performance of the solar collector was assessed. At Reynolds numbers of 104, 105 and 106, as direct normal irradiance increased from 900 to 1100 W m−2, Nu increased by up to 8.6%, 9.78% and 11.43%, respectively, leading to increases in thermal efficiency of 3.87%, 3.82% and 2.04%. This study provides new insight into the effect of Cu nanoparticle addition on the thermal and flow characteristics of parabolic-trough solar collectors.

Similar content being viewed by others

Abbreviations

- \(C_{\text{d}}\) :

-

Inertial coefficient

- C p :

-

Specific heat (J kg−1 K−1)

- C R :

-

Concentration of the receiver tube

- D :

-

Diameter of the base fluid molecule (m)

- I :

-

Direct normal irradiance

- d p :

-

Diameter of the nanoparticle (m)

- d gi :

-

Inner diameter of receiver’s glass cover (m)

- d ri :

-

Inner diameter of the absorber tube (m)

- T 0 :

-

Bulk temperature (K)

- T :

-

Temperature (K)

- F :

-

Dimensionless friction factor

- G :

-

Gravitational acceleration (m s−2)

- HTF:

-

Heat transfer fluid

- H :

-

Heat transfer coefficient (W m−2 K−1)

- K :

-

Consistency index

- K :

-

Permeability

- \(\Delta P\) :

-

Pressure drop (Pa)

- P :

-

Pressure (Pa)

- \(\vec{v}\) :

-

Velocity field (m s−1)

- PTC:

-

Parabolic-trough collector

- Q :

-

Heat flux

- Re:

-

Reynolds number

- avg:

-

Average

- eff:

-

Effective

- w:

-

Wall

- f:

-

Base fluid

- fr:

-

Reference

- h:

-

Hydrodynamic

- in:

-

Inlet

- m:

-

Mixture (nanofluid)

- p:

-

Nanoparticle

- tot:

-

Total

- x, y, z :

-

Cartesian coordinates (m)

- Α :

-

Thermal diffusivity (m2 s−1)

- \(\alpha_{\text{t}}\) :

-

Turbulent thermal diffusivity (m2 s−1)

- Β :

-

Thermal expansion coefficient (K−1)

- \(\sigma_{\upvarepsilon}\) :

-

Prandtl number for turbulent dissipation rate

- \(\sigma_{\text{k}}\) :

-

Prandtl number for turbulent kinetic energy

- \(\vartheta\) :

-

Nanoparticle volume fraction

- \(\eta\) :

-

Thermal efficiency

- \(\lambda\) :

-

Thermal conductivity (W m−1 K−1)

- Μ :

-

Dynamic viscosity (kg m−1 s−1)

- Ρ :

-

Density (kg m−3)

- \(\sigma\) :

-

Stefan–Boltzmann constant (W m−2 K−4)

References

Ziviani D, Beyene A, Venturini M. Design, analysis and optimization of a micro CHP system based on organic rankine cycle for ultralow grade thermal energy recovery. J Energy Resour Technol. 2014;136:11602.

Calderón A, Palacios A, Barreneche C, Segarra M, Prieto C, Rodriguez-Sanchez A, et al. High temperature systems using solid particles as TES and HTF material: a review. Appl Energy. 2018;213:100–11.

Athar K, Doranehgard MH, Eghbali S, Dehghanpour H. Measuring diffusion coefficients of gaseous propane in heavy oil at elevated temperatures. J Therm Anal Calorim. 2019;1–13. https://doi.org/10.1007/s10973-019-08768-7.

Siavashi M, Doranehgard MH. Particle swarm optimization of thermal enhanced oil recovery from oilfields with temperature control. Appl Therm Eng. 2017;123:658–69.

Doranehgard MH, Siavashi M. The effect of temperature dependent relative permeability on heavy oil recovery during hot water injection process using streamline-based simulation. Appl Therm Eng. 2018;129:106–16.

Mesbah M, Vatani A, Siavashi M, Doranehgard MH. Parallel processing of numerical simulation of two-phase flow in fractured reservoirs considering the effect of natural flow barriers using the streamline simulation method. Int J Heat Mass Transf. 2019;131:574–83.

Ahmadpour M, Siavashi M, Doranehgard MH. Numerical simulation of two-phase flow in fractured porous media using streamline simulation and IMPES methods and comparing results with a commercial software. J Cent South Univ. 2016;23:2630–7.

Xiong Q, Yeganeh MM, Yaghoubi E, Asadi A, Doranehgard MH, Hong K. Parametric investigation on biomass gasification in a fluidized bed gasifier and conceptual design of gasifier. Chem Eng Process Intensif. 2018;127:271–91.

Bidabadi M, Harati M, Xiong Q, Yaghoubi E, Doranehgard MH, Aghajannezhad P. Volatization & combustion of biomass particles in random media: mathematical modeling and analyze the effect of Lewis number. Chem Eng Process Intensif. 2018;126:232–8.

Gao W, Wang S, Li D-X, Liu J-B, Farahini MR, Huo Y, et al. Farahini MR, Huo Y, et al. Techno-economic evaluation of biomass-to-synthesis gas (BtS) based on gasification. Energy Sources Part B Econ Plan Policy. 2018;13:83–90.

Yaghoubi E, Xiong Q, Doranehgard MH, Yeganeh MM, Shahriari G, Bidabadi M. The effect of different operational parameters on hydrogen rich syngas production from biomass gasification in a dual fluidized bed gasifier. Chem Eng Process Intensif. 2018;126:210–21.

Asadi A, Kadijani ON, Doranehgard MH, Bozorg MV, Xiong Q, Shadloo MS, et al. Numerical study on the application of biodiesel and bioethanol in a multiple injection diesel engine. Renew Energy; 2019. https://doi.org/10.1016/j.renene.2019.11.088.

Asadi A, Zhang Y, Mohammadi H, Khorand H, Rui Z, Doranehgard MH, et al. Combustion and emission characteristics of biomass derived biofuel, premixed in a diesel engine: a CFD study. Renew Energy. 2019;138:79–89.

Bidabadi M, Bozorg MV, Bordbar V, Ahmadi G. Flame propagation through heterogeneous combustion of hybrid aluminum-boron poly-disperse particle suspensions in air. Fuel. 2018;215:714–25.

Bozorg MV, Doranehgard MH, Hong K, Xiong Q, Li LKB. A numerical study on discrete combustion of polydisperse magnesium aero-suspensions. Energy; 2019;194:116872.

Bozorg MV, Bidabadi M, Bordbar V. Numerical investigation of flame behavior and quenching distance in randomly distributed poly-dispersed iron dust cloud combustion within a narrow channel. J Hazard Mater. 2019;367:482–91.

Bidabadi M, Bozorg MV, Bordbar V. A three-dimensional simulation of discrete combustion of randomly dispersed micron-aluminum particle dust cloud and applying genetic algorithm to obtain the flame front. Energy. 2017;140:804–17.

Suman S, Khan MK, Pathak M. Performance enhancement of solar collectors—a review. Renew Sustain Energy Rev. 2015;49:192–210.

Saffarian MR, Moravej M, Doranehgard MH. Heat transfer enhancement in a flat plate solar collector with different flow path shapes using nanofluid. Renew Energy. 2020;146:2316–29.

Mokheimer EMA, Dabwan YN. Performance analysis of integrated solar tower with a conventional heat and power co-generation plant. J Energy Resour Technol. 2019;141:21201.

Reddy KS, Kumar KR, Ajay CS. Experimental investigation of porous disc enhanced receiver for solar parabolic trough collector. Renew Energy. 2015;77:308–19.

Fernández-Garc\’\ia A, Zarza E, Valenzuela L, Pérez M. Parabolic-trough solar collectors and their applications. Renew Sustain Energy Rev. 2010;14:1695–721.

Pandya B, Kumar V, Patel J, Matawala VK. Optimum heat source temperature and performance comparison of LiCl–H2O and LiBr–H2O type solar cooling system. J Energy Resour Technol. 2018;140:51204.

Sandeep HM, Arunachala UC. Solar parabolic trough collectors: a review on heat transfer augmentation techniques. Renew Sustain Energy Rev. 2017;69:1218–31.

Bozorg MV, Doranehgard MH, Hong K, Xiong Q. CFD study of heat transfer and fluid flow in a parabolic trough solar receiver with internal annular porous structure and synthetic oil–Al2O3 nanofluid. Renew Energy. 2020;145:2598–614.

Ghasemi SE, Ranjbar AA. Effect of using nanofluids on efficiency of parabolic trough collectors in solar thermal electric power plants. Int J Hydrog Energy. 2017;42:21626–34.

Wang Y, Xu J, Liu Q, Chen Y, Liu H. Performance analysis of a parabolic trough solar collector using Al2O3/synthetic oil nanofluid. Appl Therm Eng. 2016;107:469–78.

Goudarzi K, Shojaeizadeh E, Nejati F. An experimental investigation on the simultaneous effect of CuO–H2O nanofluid and receiver helical pipe on the thermal efficiency of a cylindrical solar collector. Appl Therm Eng. 2014;73:1236–43.

Bellos E, Tzivanidis C, Antonopoulos KA, Gkinis G. Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew Energy. 2016;94:213–22.

Rahimi A, Kasaeipoor A, Amiri A, Doranehgard MH, Malekshah EH, Kolsi L. Lattice Boltzmann method based on Dual-MRT model for three-dimensional natural convection and entropy generation in CuO–water nanofluid filled cuboid enclosure included with discrete active walls. Comput Math Appl. 2018;75:1795–813.

Xiong Q, Bozorg MV, Doranehgard MH, Hong K, Lorenzini G. A CFD investigation of the effect of non-Newtonian behavior of Cu–water nanofluids on their heat transfer and flow friction characteristics. J Therm Anal Calorim; 1–21. https://doi.org/10.1007/s10973-019-08757-w.

Siavashi M, Karimi K, Xiong Q, Doranehgard MH. Numerical analysis of mixed convection of two-phase non-Newtonian nanofluid flow inside a partially porous square enclosure with a rotating cylinder. J Therm Anal Calorim. 2019;137:267–87.

Gholamalipour P, Siavashi M, Doranehgard MH. Eccentricity effects of heat source inside a porous annulus on the natural convection heat transfer and entropy generation of Cu-water nanofluid. Int Commun Heat Mass Transf. 2019;109:104367.

Mahian O, Kianifar A, Heris SZ, Wongwises S. First and second laws analysis of a minichannel-based solar collector using boehmite alumina nanofluids: effects of nanoparticle shape and tube materials. Int J Heat Mass Transf. 2014;78:1166–76.

Mahian O, Kianifar A, Sahin AZ, Wongwises S. Entropy generation during Al2O3/water nanofluid flow in a solar collector: effects of tube roughness, nanoparticle size, and different thermophysical models. Int J Heat Mass Transf. 2014;78:64–75.

Bellos E, Tzivanidis C, Tsimpoukis D. Enhancing the performance of parabolic trough collectors using nanofluids and turbulators. Renew Sustain Energy Rev. 2018;91:358–75.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, et al. Recent advances in modeling and simulation of nanofluid flows-part I: fundamental and theory. Phys Rep; 2018. https://doi.org/10.1016/j.physrep.2018.11.004.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, et al. Recent advances in modeling and simulation of nanofluid flows-part II: applications. Phys Rep. 2018. https://doi.org/10.1016/j.physrep.2018.11.003.

Sarafraz MM, Safaei MR, Tian Z, Goodarzi M, Bandarra Filho EP, Arjomandi M. Thermal assessment of nano-particulate graphene-water/ethylene glycol (WEG 60: 40) nano-suspension in a compact heat exchanger. Energies. 2019;12:1929.

Sarafraz MM, Nikkhah V, Nakhjavani M, Arya A. Thermal performance of a heat sink microchannel working with biologically produced silver-water nanofluid: experimental assessment. Exp Therm Fluid Sci. 2018;91:509–19.

Sarafraz MM, Arjomandi M. Thermal performance analysis of a microchannel heat sink cooling with Copper Oxide-Indium (CuO/In) nano-suspensions at high-temperatures. Appl Therm Eng. 2018;137:700–9.

Derakhshan S, Khosravian M. Exergy optimization of a novel combination of a liquid air energy storage system and a parabolic trough solar collector power plant. J Energy Resour Technol. 2019;141:81901.

Mwesigye A, Huan Z, Meyer JP. Thermal performance and entropy generation analysis of a high concentration ratio parabolic trough solar collector with Cu-Therminol{®} VP-1 nanofluid. Energy Convers Manag. 2016;120:449–65.

Khanafer K, Vafai K. A critical synthesis of thermophysical characteristics of nanofluids. Int J Heat Mass Transf. 2011;54:4410–28.

Haddad Z, Oztop HF, Abu-Nada E, Mataoui A. A review on natural convective heat transfer of nanofluids. Renew Sustain Energy Rev. 2012;16:5363–78.

Zhou S-Q, Ni R. Measurement of the specific heat capacity of water-based Al2O3 nanofluid. Appl Phys Lett. 2008;92:93123.

Corcione M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag. 2011;52:789–93.

Bergman TL, Incropera FP, DeWitt DP, Lavine AS. Fundamentals of heat and mass transfer. New York: Wiley; 2011.

Spalding DB. A novel finite difference formulation for differential expressions involving both first and second derivatives. Int J Numer Methods Eng. 1972;4:551–9.

Patankar S. Numerical heat transfer and fluid flow. Cambridge: CRC Press; 1980.

Cengel YA, Ghajar AJ, Kanoglu M. Fundamentals of Thermal Radiation. Heat Mass Transf Fundam Appl. 2011.

Acknowledgements

This work was supported by the Natural Science Foundation of the Higher Education Institutions of Jiangsu Province (17KJA530001) and Foundation of Huaian Municipal Science and Technology Bureau (HAA201734). Dr. Hong thanks the support of Six Talent Peaks Project of Jiangsu Province (2018-XNY-004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hong, K., Yang, Y., Rashidi, S. et al. Numerical simulations of a Cu–water nanofluid-based parabolic-trough solar collector. J Therm Anal Calorim 143, 4183–4195 (2021). https://doi.org/10.1007/s10973-020-09386-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09386-4