Abstract

This paper focuses on an experimental study of the surface tension of nanofluids based on ethylene glycol with various types of nitride nanoparticles. Samples were prepared using a two-step method with mass content between 1 and 5% of particles. Nanofluids contain three types of nitride nanoparticles: aluminum nitride, silicon nitride and titanium nitride with various particle average sizes. Surface tension of nanofluids was investigated at a constant temperature of 298.15 K with two different techniques: du Noüy ring method and pendant drop method. It is presented that experimental values obtained with both methods are in good agreement with each other. Also, results obtained during this study show that the addition of this type of nanoparticles does not have a significant impact on the surface tension of base fluid for the concentrations and diameters of nitride nanoparticles considered.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Choi and Eastman [1] presented the results of their work on thermal conductivity of suspensions containing nanoparticles. The word nanofluid appeared in the scientific literature for the first time. However, the first paper on the thermal conductivity of suspension of nanoparticles was presented by Masuda et al. [2]. As described in those papers, adding nanoparticles enhances the thermal conductivity of fluids which brings an expectation that using nanofluids in heat exchangers and advanced power systems could lead to the increase in their efficiency. Those results coincided with those of the worldwide discussion on improving the efficiency of energy systems, resulting in the 1997 Kyoto agreement being signed. Since then many research papers on potential application of nanofluids were presented. Some of them have been summarized in recent review papers [3,4,5,6,7,8,9,10,11].

For the last 20 years, many research activities were carried out to understand the mechanism behind changes in physical properties of fluids after adding nanoparticles to them. Part of that research was the experimental studies on the properties of nanofluids which has been presented and summarized in the literature. In addition to the review papers on thermal conductivity [12,13,14,15,16], one can find interesting reviews on rheological properties [17,18,19,20,21], heat capacity [22], breakdown voltage [23], and dielectric properties [24]. Recently, a lot of work on modeling nanofluids flow has been done, as summarized in Refs. [25, 26].

Considering potential applications of nanofluids, not only thermal conductivity and viscosity should be taken into account, but also other physical properties such as surface tension (ST) which may become a key-role parameter. In a recent review paper by Estellé et al. [27], the state-of-the-art findings in the field of surface tension studies have been presented. Authors summarized results of experimental investigations on the influence of temperature, fraction of particles and their size on surface tension of nanofluids. Besides reviewing previous experimental investigations, they discussed some thermal configurations and applications on which surface tension has an influence, and those properties are listed in Fig. 1.

Thermal configurations and applications in which surface tension plays a main role. Detailed discussion of each of them could be found in Ref. [27]

According to the authors' best knowledge, there are only a few papers on the surface tension of ethylene glycol-based nanofluids available in the literature. Moosavi et al. [28] examined the surface tension of ZnO-EG nanofluids with du Noüy ring method. They observed an increase in the surface tension with volume fraction of particles. Harikrishnan et al. [29] used pendant drop method to measure surface tension of Bi\(_2\)O\(_3\)-EG and CuO-EG at 303.15 K. They noted that the surface tension of those nanofluids does not increase with the mass concentration of nanoparticles in suspension.

This paper focuses on the surface tension of ethylene glycol-based nanofluids containing three different types of nitrides, namely aluminum nitride (AlN), silicon nitride (Si\(_3\)N\(_4\)) and titanium nitride (TiN). Other physical properties of those nanosuspensions, such as thermal conductivity, viscosity, density and isobaric heat capacity, have been previously investigated, and results of those studies could be found elsewhere [30,31,32,33]. Nanofluids have been prepared with a two-step method, and two sizes of particles of each type of nitride has been employed. Measurements of surface tension has been conducted using two (different) techniques, and it allows comparing results and provides information on the consistency of techniques.

Sample preparation

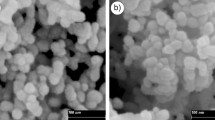

Three types of nanoparticles, each with two different particle sizes, were used in this research: aluminum nitride with size of 20 nm and 50 nm (labeled throughout the paper as AlN20 and AlN50, respectively), silicon nitride with an average size of 20 nm and 80 nm (Si\(_3\)N\(_4\)20 and Si\(_3\)N\(_4\)80) and titanium nitride with average size of 20 nm and 50 nm (TiN20 and TiN50). Information about the physical properties of those nanoparticles is summarized in Table 1, and scanning electron microscopy (SEM) pictures of these materials are presented in Fig. 2.

SEM images of dry nanoparticles: a AlN20 at [\(\times\)90,000] magnification, b AlN50 [\(\times\)85,000], c Si\(_3\)N\(_4\)20 [\(\times\)60,000], d Si\(_3\)N\(_4\)80 [\(\times\)80,000], e TiN20 [\(\times\)100,000] and f TiN50 [\(\times\)130,000]. Reused with permission from Ref. [33]

All samples were prepared with a two-step method: Dry nanoparticles were dispersed in base fluid–ethylene glycol. Nanofluids were prepared with three mass fractions of nanoparticles in suspensions: 0.01, 0.025 and 0.05. The amounts of base fluid and nanoadditives necessary to obtain desired concentrations were weighed on an analytical balance WAS 220/X (Radwag, Radom, Poland). Then mechanical mixing using a Genius 3 Vortex (IKA, Staufen, Germany) was applied for 30 min. After that, ultrasonic bath Emmi 60 HC (EMAG, Moerfelden-Walldorf, Germany) was employed to sonicate samples for 200 min to break down remaining agglomerates.

Methods

In this study, two different methods of surface tension measurement were considered. The first was du Noüy ring method used in tensionmeter PI-MT1A.KOM (Polon-Izot, Warsaw, Poland), and the second one was pendant drop method used in Drop Shape Analyzer (KRÜSS GmbH, Hamburg, Germany). Basic principles of both methods are described in the following subsections.

Du Noüy’s ring method

Visual presentation of du Noüy ring method is depicted in Fig. 3a). In the first step, platinum–iridium ring is immersed in liquid and then pulled up with constant speed (0.1 m s\(^{-1}\)) until it is detached from the sample.

Tensionmeter PI-MT1A.KOM uses du Noüy’s ring method in the following manner. Twenty-five milliliters of sample is placed in a vessel whose temperature is controlled with 0.1 K accuracy by means of a Peltier system. Ring is hung under analytical balance (which measure mass with uncertainty of 0.0001 g). While moving down the vessel, surface tension resists the force trying to detach the ring from the fluid, which makes it possible to calculate the maximum force necessary to pull up the ring. The maximum value of ST (just before detachment) is presented in Fig. 3b). Reported experimental values of surface tension measured with this method were calculated as an average of ten measurements.

To define the uncertainty of surface tension measurements conducted with this equipment, ten measurements of surface tension of pure EG at 298.15 K were performed. Obtained result 47.49 mN m\(^{-1}\) with standard deviation 0.03 mN m\(^{-1}\) is in good agreement with NIST literature values (48.11 mN m\(^{-1}\) [35, 36], 48.6 mN m\(^{-1}\) [37], 48.03 mN m\(^{-1}\) [38], 47.14 mN m\(^{-1}\) [39], 47.89 mN m\(^{-1}\) [40]). Taking into account those factors, the relative uncertainty was estimated as 1%. Figure 4 shows the value of surface tension obtained in this examination (solid line), with 1% relative uncertainty area (doted lines), and literature values.

Comparison value of surface tension, \(\gamma\), for pure ethylene glycol at 298.15 K with literature data a results obtained with du Noüy ring method, b results obtained with pendant drop method. Points are values from the NIST literature [35,36,37,38,39,40]; solid lines represent the experimentally determined surface tension in this work, and the dotted lines express 1% measurement relative uncertainty

Pendant drop method

Drop Shape Analyzer uses pendant drop method to measure surface tension between air and fluid. In this method, fluid droplet is produced at the end of a blunt needle, image of a drop is captured by a camera and then analyzed by software with Young–Laplace equation [41]. Defined uncertainty of device was achieved by measuring surface tension ten times for each of the three examined drops of EG at 298.15 K. Obtained in this examination value (47.53 mN m\(^{-1}\) with standard deviation 0.05 mN m\(^{-1}\)) is in good agreement with NIST data, as presented in Fig. 4. A comprehensive description of experimental procedure and its validation with water can be found elsewhere [42]. Finally, the relative uncertainty of the surface tension measurement with this equipment was evaluated as 1% as presented in Ref. [32].

Environmental chamber (KRÜSS GmbH, Hamburg, Germany) allows controlling the temperature of the sample with an accuracy of 0.1 K. Experimental values of ST presented in this paper were obtained with pendant drop method as an average from ten analyses for three different droplets. Representative image of the system during measurements is presented in Fig. 5.

Sample image of measuring the surface tension of pure ethylene glycol with pendant drop method on Drop Shape Analyzer (KRUSS GmbH, Hamburg, Germany). Reused with permission from Ref. [32]

Performed measurements

Measurements were performed with both devices at the same temperature 298.15 K, and samples were stabilized for at least 10 min prior to measurements. All nanofluids were stable during experiments as seen from pendant drop measurement, drop volume keeping constant with time. Both techniques require information about the density of nanofluids in order to measure ST; same values were taken from experimental results on density of those materials presented in Ref. [33].

Results and discussion

Surface tension results obtained for the different nitride nanofluids using both experimental methods are summarized in Table 2.

In the case of nanofluids containing AlN nanoparticles with 20 nm diameter, both methods show that ST increases slightly with the concentration of nanoadditions. Values of surface tension for sample including 1% of AlN nanoparticles are: 47.44 mN m\(^{-1}\) for du Noüy ring method and 47.52 mN m\(^{-1}\) for pendant drop method, which are just slightly less than those for pure ethylene glycol (47.49 mN m\(^{-1}\) and 47.53 mN m\(^{-1}\), respectively). For one containing 5% of AlN, results are: 47.65 mN m\(^{-1}\) and 47.78 mN m\(^{-1}\). Data of ST of AlN20-EG nanofluids are presented in Fig. 6a) for du Noüy ring method, Fig. 6b) for pendant drop method, and Fig. 6c) comparison of results from both methods.

Dependence of surface tension, \(\gamma\), on mass fraction, \(\varphi _{\rm m}\), of nanoparticles at 298.15 K for a AlN20-EG—du Noüy ring method, b AlN20-EG—pendant drop method, c AlN20-EG—comparison of results obtained with both methods, d AlN50-EG—du Noüy ring method, e AlN50-EG—pendant drop method, f AlN50-EG—comparison of results obtained with both methods. Points are experimental results, and dotted lines express 1% uncertainty of the pure EG surface tension value

Results obtained for AlN-EG nanofluid with particle size of 50 nm show almost constant value for all concentrations with du Noüy ring method, which is almost the same as ST of EG 47.49 mN m\(^{-1}\) (maximum difference is 0.06 mN m\(^{-1}\) for one containing 2.5% of nanoparticles). Data gained with the pendant drop method show a decrease in ST for 1% mass concentration 47.09 mN m\(^{-1}\) and an increase with concentration up to 47.70 mN m\(^{-1}\) for sample containing mass concentration of 5% of AlN50. Values of surface tension of AlN50-EG nanofluids are shown in Fig. 6d) obtained with du Noüy ring method, Fig. 6e) for pendant drop method, and Fig. 6f) comparison of results from both methods.

For Si\(_3\)N\(_4\)20-EG, ST values oscillate around value of 47.49 mN m\(^{-1}\) (ST of pure EG) for both measurement methods. Slight increase in the surface tension is visible for samples containing 1% of nanoparticles (47.51 mN m\(^{-1}\)), while results are close to those of EG for samples with 5% Si\(_3\)N\(_4\)20 (47.46 mN m\(^{-1}\)). These results are presented in Fig. 7a) for du Noüy ring method, Fig. 7b) for pendant drop method, and Fig. 7c) comparison of results from both methods.

Dependence of surface tension, \(\gamma\), on mass fraction, \(\varphi _{\rm m}\), of nanoparticles at 298.15 K for a Si\(_3\)N\(_4\)20-EG—du Noüy ring method, b Si\(_3\)N\(_4\)20-EG—pendant drop method, c Si\(_3\)N\(_4\)20-EG—comparison of results obtained with both methods, d Si\(_3\)N\(_4\)80-EG—du Noüy ring method, e Si\(_3\)N\(_4\)80-EG–pendant drop method, f Si\(_3\)N\(_4\)80-EG—comparison of results obtained with both methods. Points are experimental results, and dotted lines express 1% uncertainty of the pure EG surface tension value

Values obtained with du Noüy ring method for nanofluids containing Si\(_3\)N\(_4\)80 show a bit of increase, highest value 47.80 mN m\(^{-1}\) for 5% nanofluid. Results from pendant drop method are centered on a value of around 47.5 mN m\(^{-1}\), which is the ST value of ethylene glycol. ST data of Si\(_3\)N\(_4\)80-EG nanofluids are presented in Fig. 7d) for du Noüy ring method, Fig. 7e) for pendant drop method, while Fig. 7f) shows a comparison of results from both methods.

Surface tension of TiN20-EG nanofluids increases with nanoparticle concentration and is observed in both methods. For sample containing 5% of TiN, nanofluid ST is 47.82 mN m\(^{-1}\) (du Noüy ring method) and 47.90 mN m\(^{-1}\) (pendant drop method), which are the highest increasements among all studied nanofluids. Data of ST of TiN20-EG nanofluids are presented in Fig. 8a for du Noüy ring method, Fig. 8b for pendant drop method, and Fig. 8c comparison of results from both methods.

Dependence of surface tension, \(\gamma\), on mass fraction, \(\varphi _{\rm m}\), of nanoparticles at 298.15 K for a TiN20-EG—du Noüy ring method, b TiN20-EG—pendant drop method, c TiN20-EG—comparison of results obtained with both methods, d TiN50-EG—du Noüy ring method, e TiN50-EG—pendant drop method, f TiN50-EG—comparison of results obtained with both methods. Points are experimental results, and dotted lines express 1% uncertainty of the pure EG surface tension value

Nanofluids with TiN50 nanoparticles also show ST increase with mass concentration which is visible for du Noüy ring method with the highest value of 47.70 mN m\(^{-1}\) for 5% addition of TiN50. Results of pendant drop method oscillate around 47.53 mN m\(^{-1}\). Surface tension values of TiN50-EG nanofluids are shown in Fig. 8d) for du Noüy ring method, Fig. 8e) for pendant drop method, and Fig. 8f) comparison of results from both methods. Slight increase in ST for TiN-EG nanofluids with fraction of the particles and higher values for samples containing nanoparticles with smaller size agreed with results obtained earlier by Żyła et al. [32].

Finally, while some changes in surface tension values were noticed from experiments, as discussed previously, they appear to be within experimental uncertainty. Hence, for the tested nanoparticles, there is no strong effect of size, morphology, surface area or concentration on the surface tension of EG-based nanofluids. Such a behavior can be attributed to the high viscosity of EG and its low polarity as explained by Harikrishnan et al. [29] who measured ST of Bi\(_2\)O\(_3\)-EG and CuO-EG nanofluids.

Conclusions

The paper presents results of experimental investigation of the surface tension of ethylene glycol-based nanofluids containing different types of nitrides. In this study, two experimental techniques were used: (a) du Noüy ring and (b) pendant drop. For each type of nitride (AlN, Si\(_3\)N\(_4\) and TiN), two different nanofluids sets, containing particles with different sizes in range 20–80 nm, were prepared. It was presented that the type of used measuring method does not affect the surface tension value obtained for these nanosuspensions. Results show that the addition of these nanoparticles in the 1–5% mass concentration range changes slightly the value of surface tension for some nanofluids, but only within experimental uncertainty.

References

Choi SUS, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Technical report. Lemont, IL: Argonne National Lab; 1995.

Masuda H, Ebata A, Teramae K. Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles. Dispersion of Al2O3, SiO2 and TiO2 ultra-fine particles. Netsu Bussei. 1993;7(4):227–33.

Wen D, Lin G, Vafaei S, Zhang K. Review of nanofluids for heat transfer applications. Particuology. 2009;7(2):141–50.

Huminic G, Huminic A. Application of nanofluids in heat exchangers: a review. Renew Sustain Energy Rev. 2012;16(8):5625–38.

Taylor R, Coulombe S, Otanicar T, Phelan P, Gunawan A, Lv W, Rosengarten G, Prasher R, Tyagi H. Small particles, big impacts: a review of the diverse applications of nanofluids. J Appl Phys. 2013;113(1):1.

Mahian O, Kianifar A, Kalogirou SA, Pop I, Wongwises S. A review of the applications of nanofluids in solar energy. Int J Heat Mass Transfer. 2013;57(2):582–94.

Wu JM, Zhao J. A review of nanofluid heat transfer and critical heat flux enhancement: research gap to engineering application. Prog Nucl Energy. 2013;66:13–24.

Verma SK, Tiwari AK. Progress of nanofluid application in solar collectors: a review. Energy Convers manag. 2015;100:324–46.

Rashidi S, Eskandarian M, Mahian O, Poncet S. Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim. 2019;135(1):437–60. https://doi.org/10.1007/s10973-018-7070-9.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems. J Therm Anal Calorim. 2018;131(3):2027–39.

Sheikhani H, Barzegarian R, Heydari A, Kianifar A, Kasaeian A, Gróf G, Mahian O. A review of solar absorption cooling systems combined with various auxiliary energy devices. J Therm Anal Calorim. 2018;134(3):2197–212.

Yu W, France DM, Routbort JL, Choi SUS. Review and comparison of nanofluid thermal conductivity and heat transfer enhancements. Heat Transfer Eng. 2008;29(5):432–60.

Özerinç S, Kakaç S, Yazıcıoğlu AG. Enhanced thermal conductivity of nanofluids: a state-of-the-art review. Microfluidics Nanofluidics. 2010;8(2):145–70.

Aybar HŞ, Sharifpur M, Azizian MR, Mehrabi M, Meyer JP. A review of thermal conductivity models for nanofluids. Heat Transfer Eng. 2015;36(13):1085–110.

Bashirnezhad K, Rashidi MM, Yang Z, Bazri S, Yan W-M. A comprehensive review of last experimental studies on thermal conductivity of nanofluids. J Therm Anal Calorim. 2015;122(2):863–84.

Asadi A, Aberoumand S, Moradikazerouni A, Pourfattah F, Żyła G, Estellé P, Mahian O, Wongwises S, Nguyen HM, Arabkoohsar A. Recent advances in preparation methods and thermophysical properties of oil-based nanofluids: a state-of-the-art review. Powder Technol. 2019;352:209–26.

Mishra PC, Mukherjee S, Nayak SK, Panda A. A brief review on viscosity of nanofluids. Int Nano Lett. 2014;4(4):109–20.

Sharma AK, Tiwari AK, Dixit AR. Rheological behaviour of nanofluids: a review. Renew Sustain Energy Rev. 2016;53:779–91.

Murshed SMS, Estellé P. A state of the art review on viscosity of nanofluids. Renew Sustain Energy Rev. 2017;76:1134–52.

Nadooshan AA, Eshgarf H, Afrand M. Evaluating the effects of different parameters on rheological behavior of nanofluids: a comprehensive review. Powder Technol. 2018;338:342–53.

Koca HD, Doganay S, Turgut A, Tavman IH, Saidur R, Mahbubul IM. Effect of particle size on the viscosity of nanofluids: a review. Renew Sustain Energy Rev. 2018;82:1664–74.

Shahrul IM, Mahbubul IM, Khaleduzzaman SS, Saidur R, Sabri MFM. A comparative review on the specific heat of nanofluids for energy perspective. Renew Sustain Energy Rev. 2014;38:88–98.

Fal J, Mahian O, Żyła G. Nanofluids in the service of high voltage transformers: breakdown properties of transformer oils with nanoparticles, a review. Energies. 2018;11(11):2942.

Ahmad F, Khan AA, Khan Q, Hussain R. State-of-art in nano-based dielectric oil: a review. IEEE Access. 2019;7:13396.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Siavashi M, Taylor RA, Niazmand H, et al. Recent advances in modeling and simulation of nanofluid flows-part I: fundamental and theory. Phys Rep. 2019;790:1–48.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Taylor RA, Abu-Nada E, Rashidi S, et al. Recent advances in modeling and simulation of nanofluid flows-part II: applications. Phys Rep. 2019;791:1–59.

Estellé P, Cabaleiro D, Żyła G, Lugo L, Murshed SMS. Current trends in surface tension and wetting behavior of nanofluids. Renew Sustain Energy Rev. 2018;94:931–44.

Moosavi M, Goharshadi EK, Youssefi A. Fabrication, characterization, and measurement of some physicochemical properties of ZnO nanofluids. Int J Heat Fluid Flow. 2010;31(4):599–605.

Harikrishnan AR, Dhar P, Agnihotri PK, Gedupudi S, Das SK. Effects of interplay of nanoparticles, surfactants and base fluid on the surface tension of nanocolloids. Eur Phys J E. 2017;40(5):53.

Żyła G, Fal J. Experimental studies on viscosity, thermal and electrical conductivity of aluminum nitride-ethylene glycol (AlN-EG) nanofluids. Thermochim Acta. 2016;637:11–6.

Żyła G, Fal J, Bikić S, Wanic M. Ethylene glycol based silicon nitride nanofluids: an experimental study on their thermophysical, electrical and optical properties. Phys E Low Dimens Syst Nanostruct. 2018;104:82–90.

Żyła G, Fal J, Estellé P. Thermophysical and dielectric profiles of ethylene glycol based titanium nitride (TiN-EG) nanofluids with various size of particles. Int J Heat Mass Transfer. 2017;113:1189–99.

Żyła G, Vallejo JP, Lugo L. Isobaric heat capacity and density of ethylene glycol based nanofluids containing various nitride nanoparticle types: an experimental study. J Mol Liquids. 2018;261:530–9.

Pierson HO. Handbook of refractory carbides and nitrides: properties, characteristics, processing and apps. Norwich: William Andrew; 1996.

Azizian S, Hemmati M. Surface tension of binary mixtures of ethanol+ ethylene glycol from 20 to 50 C. J Chem Eng Data. 2003;48(3):662–3.

Azizian S, Bashavard N. Surface tensions of dilute solutions of cycloheptanol in ethylene glycol. J Chem Eng Data. 2005;50(3):1091–4.

Azizian S, Bashavard N. Surface properties of pure liquids and binary liquid mixtures of ethylene glycol+ methylcyclohexanols. J Chem Eng Data. 2004;49(4):1059–63.

Azizian S, Bashavard N. Equilibrium surface tensions of benzyl alcohol+ ethylene glycol mixtures. J Chem Eng Data. 2005;50(2):709–12.

Jimenez E, Cabanas M, Segade L, Garcia-Garabal S, Casas H. Excess volume, changes of refractive index and surface tension of binary 1, 2-ethanediol+ 1-propanol or 1-butanol mixtures at several temperatures. Fluid Phase Equilib. 2001;180(1–2):151–64.

Rafati AA, Ghasemian E, Abdolmaleki M. Surface properties of binary mixtures of ethylene glycol with a series of aliphatic alcohols (1-pentanol, 1-hexanol, and 1-heptanol). J Chem Eng Data. 2008;53(8):1944–9.

Berry JD, Neeson MJ, Dagastine RR, Chan DYC, Tabor RF. Measurement of surface and interfacial tension using pendant drop tensiometry. J Colloid Interface Sci. 2015;454:226–37.

Gómez-Villarejo R, Aguilar T, Hamze S, Estellé P, Navas J. Experimental analysis of water-based nanofluids using boron nitride nanotubes with improved thermal properties. J Mol Liq. 2019;277:93–103.

Acknowledgements

Research was partially supported by EU COST Action CA15119: Overcoming Barriers to Nanofluids Market Uptake. MW acknowledges EU COST for the STSM Grant Ref. COST-STSM-CA15119-42458. DC was a recipient of a postdoctoral fellowship from Xunta de Galicia (Spain) and acknowledges EU COST for the STSM Grant Ref. COST-STSM-CA15119-42918. PE acknowledges the European Union through the European Regional Development Fund (ERDF), the Ministry of Higher Education and Research, the French region of Brittany and Rennes Métropole for the financial support of surface tension experimental device.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wanic, M., Cabaleiro, D., Hamze, S. et al. Surface tension of ethylene glycol-based nanofluids containing various types of nitrides. J Therm Anal Calorim 139, 799–806 (2020). https://doi.org/10.1007/s10973-019-08512-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08512-1