Abstract

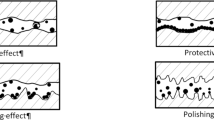

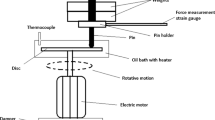

Today, nanoparticles are used as additives because of their unique properties. The aim of the present research is to investigate the effect of the addition of TiO2 nanoparticles to pure oil on properties such as viscosity, viscosity index, flash point, density, friction coefficient and frictional force in the pin-on-disk system. For this purpose, the nanofluids were synthesized using turbine meter oil as a base oil and TiO2 additive with 0.05, 0.1, 0.2, 0.3, 0.4 and 1 mass% and oleic acid surfactants, followed by testing the mentioned properties. The results show that the kinematic viscosity of the oil is increased with increasing nanoparticles and reducing the temperature. Viscosity index and flash point temperature in 0.4 mass% were increased by 6.65% and 1.77%, respectively. The pour point temperature in 0.05–0.2 mass% was increased by 3%. A pin-on-disk system was used to measure the friction coefficient and the frictional force between the pin and disk in the presence of pure oil and nanofluids after 2 h of abrasion. The results showed that friction coefficient and frictional force were, respectively, decreased by 37.1% and 37.1% by adding 0.1 mass% of TiO2. The depth of the abrasive pins for 4 h was measured by the SEM analysis. The addition of TiO2 nanoparticles showed the lowest abrasion and the most improvement were related to 0.1 mass% TiO2 nanoparticles with a wear depth of 38.46 μm. Compared with turbine meter oil, it shows a 71.43% improvement.

Similar content being viewed by others

References

Yu W, Xie H. A review on nanofluids: preparation, stability mechanisms, and applications. J Nanomater. 2012;2012:1–17. https://doi.org/10.1155/2012/435873.

Wu YY, Tsui WC, Liu TC. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear. 2007;262(7–8):819–25. https://doi.org/10.1016/j.wear.2006.08.021Get.

Kao MJ, Lin CR. Evaluating the role of spherical titanium oxide nanoparticles in reducing friction between two pieces of cast iron. J Alloy Compd. 2009;483(1–2):456–9. https://doi.org/10.1016/j.jallcom.2008.07.223.

Hu KH, Hu XG, Xu YF, Huang F, Liu JS. The effect of morphology on the tribological properties of MoS2 in liquid paraffin. Tribol Lett. 2010;40(1):155–65. https://doi.org/10.1007/s11249-010-9651-z.

Hwang Y, Lee C, Choi Y, Cheong S, Kim D, Lee K, Lee J, Kim SH. Effect of the size and morphology of particles dispersed in nano-oil on friction performance between rotating discs. J Mech Sci Technol. 2011;25(11):2853–7. https://doi.org/10.1007/s12206-011-0724-1.

Sabareesh RK, Gobinath N, Sajith V, Das S, Sobhan CB. Application of TiO2 nanoparticles as a lubricant-additive for vapor compression refrigeration systems–An experimental investigation. Int J Refrig. 2012;35(7):1989–96. https://doi.org/10.1016/j.ijrefrig.2012.07.002.

Ettefaghi E, Ahmadi H, Rashidi A, Mohtasebi SS, Soltani R. Effects of nano-particles on properties of engine oil and its functionality rate on wear reduction. J Engine Res. 2012; 24: 3–12. http://engineresearch.ir/article-1-261-en.html.

Ingole S, Charanpahari A, Kakade A, Umare SS, Bhatt DV, Menghani J. Tribological behavior of nano TiO2 as an additive in base oil. Wear. 2013;301(1–2):776–85. https://doi.org/10.1016/j.wear.2013.01.037.

Beheshti A, Shanbedi M, Heris SZ. Heat transfer and rheological properties of transformer oil-oxidized MWCNT nanofluid. J Therm Anal Calorim. 2014;118(3):1451–60. https://doi.org/10.1007/s10973-014-4048-0.

Ali MK, Xianjun H. Improving the tribological behavior of internal combustion engines via the addition of nanoparticles to engine oils. Nanotechnol Rev. 2015;4(4):347–58. https://doi.org/10.1515/ntrev-2015-0031.

Zhelezny VP, Lukianov NN, Khliyeva OY, Nikulina AS, Melnyk AV. A complex investigation of the nanofluids R600a-mineral oil-AL2O3 and R600a-mineral oil-TiO2.Thermophysical properties. Int J Refrig. 2017;74:488–504. https://doi.org/10.1016/j.ijrefrig.2016.11.008.

Salimi-Yasar H, Heris SZ, Shanbedi M. Influence of soluble oil-based TiO2 nanofluid on heat transfer performance of cutting fluid. Tribol Int. 2017;112:147–54. https://doi.org/10.1016/j.triboint.2017.04.004.

Esfe MH. On the evaluation of the dynamic viscosity of non-Newtonian oil based nanofluids. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6903-2.

Shababi K, Firouzi M, Fakhar A. An experimental study on rheological behavior of SAE50 engine oil. J Therm Anal Calorim. 2018;131(3):2311–20. https://doi.org/10.1007/s10973-017-6693-6.

Naddaf A, Heris SZ. Density and rheological properties of different nanofluids based on diesel oil at different mass concentrations. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7456-8.

Goodarzi M, Toghraie D, Reiszadeh M, Afrand M. Experimental evaluation of dynamic viscosity of ZnO–MWCNTs/engine oil hybrid nanolubricant based on changes in temperature and concentration. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7707-8.

Qiu L, Guo P, Zou H, Feng Y, Zhang X, Pervaiz S, Wen D. Extremely low thermal conductivity of graphene nanoplatelets using nanoparticle decoration. ES Energy Environ. 2018. https://doi.org/10.30919/esee8c139.

Qiu L, Zou H, Zhu N, Feng Y, Zhang X, Zhang X. Iodine nanoparticle-enhancing electrical and thermal transport for carbon nanotube fibers. Appl Therm Eng. 2018;141:913–20. https://doi.org/10.1016/j.applthermaleng.2018.06.049.

Qiu L, Zou H, Wang X, Feng Y, Zhang X, Zhao J, Zhang X, Li Q. Enhancing the interfacial interaction of carbon nanotubes fibers by Au nanoparticles with improved performance of the electrical and thermal conductivity. Carbon. 2019;141:497–505. https://doi.org/10.1016/j.carbon.2018.09.073.

Xu Y, Geng J, Peng Y, Liu Z, Yu J, Hu X. Lubricating mechanism of Fe3O4@ MoS2 core-shell nanocomposites as oil additives for steel/steel contact. Tribol Int. 2018;121:241–51. https://doi.org/10.1016/j.triboint.2018.01.051.

Kole M, Dey TK. Effect of aggregation on the viscosity of copper oxide–gear oil nanofluids. Int J Therm Sci. 2011;50(9):1741–7. https://doi.org/10.1016/j.ijthermalsci.2011.03.027.

Sango A, La Rocca A, Shayler P. Investigating the effect of carbon nanoparticles on the viscosity of lubricant oil from light duty automotive diesel engines. SAE Tech Pap. 2014;01:1480–4. https://doi.org/10.4271/2014-01-1481.

Kotia A, Ghosh SK. Experimental analysis for rheological properties of aluminium oxide (Al2O3)/gear oil (SAE EP-90) nanolubricant used in HEMM. Ind Lubr Tribol. 2015;67(6):600–5. https://doi.org/10.1108/ILT-03-2015-0029.

Yang M, Zhu X, Ren G, Men X, Guo F, Li P, Zhang Z. Tribological behaviors of polyurethane composite coatings filled with ionic liquid core/silica gel shell microcapsules. Tribol Lett. 2015;58(1):1–9. https://doi.org/10.1007/s11249-015-0492-7.

Dubey MK, Bijwe J, Ramakumar SS. Nano-PTFE: new entrant as a very promising EP additive. Tribol Int. 2015;87:121–31. https://doi.org/10.1016/j.triboint.2015.01.026.

Fedele L, Colla L, Minetto S, Scattolini M, Bellomare F, Bobbo S, Zin V. Nanofluids characterization and application as nanolubricants in heat pump systems. Sci Technol Built Environ. 2015;21(5):621–30.

Ghasemi R, Fazlali A, Mohammadi AH. Effects of TiO2 nanoparticles and oleic acid surfactant on the rheological behavior of engine lubricant oil. J Mol Liq. 2018;268:925–30. https://doi.org/10.1016/j.molliq.2018.07.002.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Siavashi M, Taylor RA, Niazmand H, Wongwises S. Recent advances in modeling and simulation of nanofluid flows-part I: fundamental and theory. Phys Rep. 2019;790:1–48. https://doi.org/10.1016/j.physrep.2018.11.004.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Taylor RA, Abu-Nada E, Rashidi S, Niazmand H. Recent advances in modeling and simulation of nanofluid flows-part II: applications. Phys Rep. 2019;791:1–59. https://doi.org/10.1016/j.physrep.2018.11.003.

Mahian O, Kianifar A, Heris SZ, Wongwises S. Natural convection of silica nanofluids in square and triangular enclosures: theoretical and experimental study. Int J Heat Mass Transf. 2016;99:792–804. https://doi.org/10.1016/j.ijheatmasstransfer.2016.03.045.

Mahian O, Kianifar A, Sahin AZ, Wongwises S. Performance analysis of a minichannel-based solar collector using different nanofluids. Energy Convers Manag. 2014;88:129–38. https://doi.org/10.1016/j.enconman.2014.08.021.

Brinkman HC. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20(4):571. https://doi.org/10.1063/1.1700493.

Sharma KV, Sarma PK, Azmi WH, Mamat R, Kadirgama K. Correlations to predict friction and forced convection heat transfer coefficients of water based nanofluids for turbulent flow in a tube. Int J Microscale Nanoscale Therm Fluid Transp Phenom. 2012;3(4):1–25.

Corcione M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag. 2011;52(1):789–93. https://doi.org/10.1016/j.enconman.2010.06.072.

Lee K, Hwang Y, Cheong S, Choi Y, Kwon L, Lee J, Kim SH. Understanding the role of nanoparticles in nano-oil lubrication. Tribol Lett. 2009;35(2):127–31. https://doi.org/10.1007/s11249-009-9441-7.

Acknowledgements

The authors would like to thank East Azarbaijan Province Gas Company for financial supports.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pourpasha, H., Zeinali Heris, S. & Asadi, A. Experimental investigation of nano-TiO2/turbine meter oil nanofluid. J Therm Anal Calorim 138, 57–67 (2019). https://doi.org/10.1007/s10973-019-08155-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08155-2