Abstract

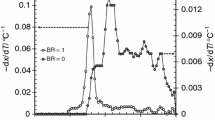

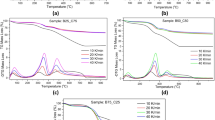

The interaction effects between sugarcane bagasse and a Brazilian coal during co-firing were investigated by means of thermal decomposition behavior, comparison between theoretical and experimental results, activation energy, and ignition temperature. The blends were prepared in the ratios of 100:0; 75:25; 50:50; 25:75; 0:100 (bagasse/coal). The interaction effect evaluated in this study was related to the interference of the bagasse volatile matter content in the coal thermal decomposition. The thermal decomposition behavior analyses were performed in a thermogravimetric balance, and the apparent activation energy was determined by two different models—model-free and local linear integral isoconversional method—under two different heating rate ranges. The results showed that the high volatile content of the sugarcane bagasse leads to more intense combustion, lower ignition temperature, and more complex reaction mechanism, as compared to coal. When the fuels are blended, there is a temperature anticipation of the events related to the decomposition of the coal portion in the mixture, the reaction rates increase and the ash formation is affected. The kinetic data also suggested that the interaction between both materials may occur and improve the burnout of the blend in relation to the pure coal firing due to the contribution of sugarcane bagasse volatile matter. Nevertheless, the presence of the bagasse did not allow to lower activation energy during the blends devolatilization process.

Similar content being viewed by others

References

Kazanç F, Khatami R, Crnkovic PM, Levendis Y. Emissions of NO x from coals of various ranks, bagasse, and coal-bagasse blends burning in O2/N2 and O2/CO2 environments. Energy Fuel. 2011;25(7):2850–61.

Gao C, Vejahaty F, Katalambula H, Gupta R. Co-gasification of biomass with coal and oil sand coke in a drop tube furnace. Energy Fuel. 2010;24:232–40.

Rasul MG, Rudolph V. Fluidized bed combustion of Australian bagasse. Fuel. 2000;79:123–30.

Woytiuk K, Sanscartier D, Amichev BY, Campbell W, Rees KV. Modeling and analysis: life-cycle assessment of torrefied coppice willow co-firing with lignite coal in an existing pulverized coal boiler. Biofuels Bioprod Bioref. 2017;11(5):830–46.

FAO—Food and Agriculture Organization of the United Nations. http://www.fao.org/docrep/003/w3647e/w3647e03.htm. Accessed 5 May 2016.

Unica—Brazilian Sugarcane Industry Association: http://www.unicadata.com.br/listagem.php?idMn=88. Accessed 5 May 2016.

BEN 2015 Report. https://ben.epe.gov.br/downloads/Relatorio_Final_BEN_2015.pdf. Accessed 5 May 2016.

Munir S, Daood SS, Nimmo W, Cunliffe AM, Gibbs BM. Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour Technol. 2009;100:1413–8.

Shen DK, Gu S, Luo KH, Bridgwater AV, Fang MX. Kinetic study on thermal decomposition of woods in oxidative environment. Fuel. 2009;88:1024–39.

Torquato LM, Braz CEM, Ribeiro CA, Capela JMV, Crespi MS. Kinetic study of the co-firing of bagasse-sludge blends. J Therm Anal Calorim. 2015;21:499–507.

Al-Qayim K, Nimmo W, Hughes K, Pourkashanian M. Kinetic parameters of the intrinsic reactivity of woody biomass and coal chars via thermogravimetric analysis. Fuel. 2017;210:811–25.

Yuzbasi NS, Seçuk N. Air and oxy-fuel combustion characteristics of biomass/lignite blends in TGA-FTIR. Fuel Process Technol. 2011;92:1101–8.

Mureddu M, Dessì F, Orsini A, Ferrara F, Pettinau A. Air- and oxygen-blown characterization of coal and biomass by thermogravimetric analysis. Fuel. 2018;212:626–37.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

El-Sayed SA, Mostafa ME. Kinetic parameters determination of biomass pyrolysis fuels using TGA and DTA techniques. Waste Biomass Valor. 2015;6:401–15.

Alwani MS, Abdul Khalil HPS, Sulaiman O, Islam MN, Dungani R. An approach to using agricultural waste fibres in biocomposites application: thermogravimetric analysis and activation energy study. BioResources. 2014;9(1):218–30.

Fermoso J, Gil M, Pevida C, Pis J, Rubiera F. Kinetic models comparison for non-isothermal steam gasification of coal–biomass blend chars. Chem Eng J. 2010;161:276–84.

Edreis EMA, Luo G, Li A, Chao C, Hua H, Zhang S, Gui B, Xiao L, Xua K, Zhang P, Yao H. CO2 co-gasification of lower sulphur petroleum coke and sugar cane bagasse via TG–FTIR analysis technique. Bioresour Technol. 2013;136:595–603.

Bragato M, Joshi K, Carlson JB, Tenório JAS, Levendis YA. Combustion of coal, bagasse and blends thereof part II: speciation of PAH emissions. Fuel. 2012;96:51–8.

Krerkkaiwan S, Fushimi C, Yamamoto H, Tsutsumi A, Kuchonthara P. Influences of heating rate during coal char preparation and AAEMs on volatile–char interaction with different sources of biomass volatile. Fuel Process Technol. 2014;119:10–8.

Kastanaki E, Vamvuka D. A comparative reactivity and kinetic study on the combustion of coal-biomass char blends. Fuel. 2006;85:1186–93.

Idris SS, Rahman NA, Ismail K, Alias AB, Rashid ZA, Aris MJ. Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour Technol. 2010;101:4584–92.

Sahu SG, Chakraborty N, Sarkar P. Coal biomass co-combustion: an overview. Renew Sust Energy Rev. 2014;39:575–86.

Demirbas A. Sustainable cofiring of biomass with coal. Energy Convers Manage. 2003;44:1465–79.

Ávila I, Crnkovic PM, Luna CMR, Milioli FE. Use of a fluidized bed combustor and thermogravimetric analyzer for the study of coal ignition temperature. Appl Therm Eng. 2017;114:984–92.

Tognotti L, Malotti A, Petarca L, Zanelli S. Measurement of ignition temperature of coal particles using a thermogravimetric technique. Combust Sci Technol. 1985;44:15–28.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;340:53–68.

Wanjun T, Donghua C. An integral method to determine variation in activation energy with extent of conversion. Thermochim Acta. 2005;433(1–2):72–6.

Da Silva DR, Crespi MS, Ribeiro CA, Capela JMV. Thermal decomposition kinetics of sugarcane mills wastes. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6270-z.

Yurdakul S. Determination of co-combustion properties and thermal kinetics of poultry litter/coal blends using thermogravimetry. Renew Energy. 2016;89:215–23.

Quensanga A, Picard C. Thermal degradation of sugar cane bagasse. Thermochim Acta. 1988;125:87–9.

Aiman S, Stubington JF. The pyrolysis kinetics of bagasse at low heating rates. Biomass Bioenergy. 1993;5(2):113–20.

Byrne CE, Nagle DC. Carbonization of wood for advanced materials applications. Carbon. 1996;35(2):259–66.

Yang H, Yan R, Chen H, Lee DH, Zheng C. Characteristics of hemicelluloses, cellulose and lignin pyrolysis. Fuel. 2007;86:1781–8.

Guimarães JI, Frollini E, Silva CG, Wypych F, Satyanarayana KG. Characterization of banana, sugarcane bagasse and sponge gourd fibers of Brazil. Ind Crop Prod. 2009;30:407–15.

Avila T, Wu E, Lester E. Estimating the spontaneous combustion potential of coals using thermogravimetric analysis. Energy Fuel. 2014;28:1765–73.

Li B, Chen G, Zhang H, Sheng CD. Development of non-isothermal TGA–DSC for kinetics analysis of low temperature coal oxidation prior to ignition. Fuel. 2014;118:385–91.

Yuanyuan Z, Yanxia G, Fangqin C, Kezhou Y, Yan C. Investigation of combustion characteristics and kinetics of coal gangue with different feedstock properties by thermogravimetric analysis. Thermochim Acta. 2015;614:137–48.

Fang X, Jia L, Yin IA. Weighted average global process model based on two-stage kinetic scheme for biomass combustion. Biomass Bioenergy. 2013;48:43–5.

Da Silva DR, Crespi MS, Crnkovic PCGM, Ribeiro CA. Pyrolysis, combustion and oxy-combustion studies of sugarcane industry wastes and its blends. J Therm Anal Calorim. 2015;121(1):309–18.

Nimmo W, Daood SS, Gibbs BM. The effect of O2 enrichment on NO x formation in biomass co-fired pulverized coal combustion. Fuel. 2010;89(10):2945–52.

Buratti C, Barbanera M, Bartocci P, Fantozzi F. Thermogravimetric analysis of the behavior of sub-bituminous coal and cellulosic ethanol residue during co-combustion. Bioresour Technol. 2015;186:154–62.

Motaunga TE, Anandjiwala RD. Effect of alkali and acid treatment on thermal degradation kinetics of sugar cane bagasse. Ind Crop Prod. 2015;74:472–7.

Brown ME, Gallagher PK. Handbook of thermal analysis and calorimetry, recent advances, techniques and applications, vol. 5. Amsterdam: Elsevier; 2008.

Faúndez J, Arias B, Rubiera F, Arenillas A, García X, Gordon AL, Pis JJ. Ignition characteristics of coal blends in an entrained flow furnace. Fuel. 2007;86:2076–80.

Riaza J, Álvarez L, Gil MV, Pevida C, Pis JJ, Rubiera F. Ignition and NO emissions of coal and biomass blends under different oxy-fuel atmospheres. Energy Proced. 2013;37:1405–12.

Acknowledgements

The authors would like to acknowledge FAPESP Research Foundation of São Paulo State (Project 2011/00183-2) and Coordenacão de Aperfeiçoamento de Pessoal de Nıvel Superior (CAPES), for the financial support provided to this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mortari, D.A., Torquato, L.D.M., Crespi, M.S. et al. Co-firing of blends of sugarcane bagasse and coal. J Therm Anal Calorim 132, 1333–1345 (2018). https://doi.org/10.1007/s10973-018-6996-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-6996-2