Abstract

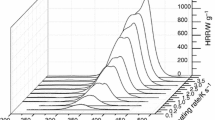

A serial of tests were carried out to evaluate the effect of specimen mass on the test results for PMMA conducted in a micro-scale combustion calorimeter. Seven heating rates were used to test specimens of mass ranging from 0.5 to 6.0 mg with nominal interval of 0.5 mg. Eighty-five specimens were tested. Heat release rate, onset temperature, temperature at maximum heat release rate, total heat release, and heat release capacity were determined. The influence of specimen mass at each heating rate was analyzed. Specimen mass influences the maximum heat release rate, onset temperature, and temperature at maximum heat release rate significantly. The higher the heating rate, the greater the influence. Reliable results could be obtained as long as the specimen mass is more than 1 mg with oxygen concentration above 5 %; thus, the oxygen concentration limit might be extended from 10 to 5 %.

Similar content being viewed by others

Abbreviations

- α :

-

Thermal diffusivity (m−2 s−1)

- β :

-

Heating rate (K s−1)

- E a :

-

Activation energy (kJ mol−1)

- h c :

-

Net calorific value of sample (J g−1)

- h c,gas :

-

Specific heat of combustion of specimen gases (J g−1)

- η c :

-

Heat release capacity (J g−1 K−1)

- K :

-

Thermodynamic temperature (K)

- M o :

-

Initial specimen mass (mg)

- Mean:

-

Mean value of test data

- \(\Delta_{{{\text{O}}_{2} }}\) :

-

The change in the concentration (volume fraction) of O2 in the gas stream (%)

- ρ :

-

Density of oxygen at ambient conditions (kg m−3)

- Q(t):

-

Specific heat release rate at time t, (W g−1)

- Q max :

-

Maximum specific heat release rate, (W g−1)

- r xy :

-

Correlation coefficient

- R :

-

General gas constant (8.314 J mol−1 K−1)

- t :

-

Time (s)

- T :

-

Temperature (°C)

- T max :

-

Temperature of maximum peak heat release rate (°C)

- T onset :

-

Onset temperature of specific heat release rate (°C)

- T P :

-

Temperature of peak pyrolysis (K)

- T P (β):

-

Temperature of maximum pyrolysis at specified heating rate (K)

- Y p :

-

Pyrolysis residue (g g−1)

- σ :

-

Standard deviation

- Φ :

-

Thermokinetic parameter (K s mg−2/3)

References

Govmark Datasheet of Micro-scale Combustion Calorimeter (MCC2), the Govmark Organization, Inc.

Lin TS, Cogen JM, Lyon RE. Correlations between microscale combustion calorimetry and conventional flammability tests for flame retardant wire and cable compounds. International Wire and Cable Symposium, Proceedings of the 56th IWCS, November 11–14, 2007.

Yang CQ, He QL. Textile heat release properties measured by microscale combustion calorimetry: experimental repeatability. Fire Mater. 2012;36:127–37.

Matala A. Methods and applications of pyrolysis modeling for polymeric materials, Doctor degree dissertation, ISSN 2242-119x, VTT Science 44, Nov. 2013.

Xiao X, Hu S, Zhai JG, Chen T, Mai YY. Thermal properties and combustion behaviors of flame-retarded glass fiber-reinforced polyamide 6 with piperazine pyrophosphate and aluminum hypophosphite. J Therm Anal Calorim. 2016;125:175–85.

Majoni S. Thermal and flammability study of polystyrene composites containing magnesium–aluminum layered double hydroxide (MgAl-C16 LDH), and an organophosphate. J Therm Anal Calorim. 2015;120:1435–43.

Chen XY, Cai XF. Synthesis of poly(diethylenetriamine terephthalamide) and its application as a flame retardant for ABS. J Therm Anal Calorim. 2016;125:313–20.

Operation Manual, MCC Microscale Combustion Calorimeter, Govmark Organization, Inc. Version 1, Oct. 2010.

Standard Test Method for Determining Flammability Characteristics of Plastics and Other Solid Materials Using Microscale Combustion Calorimetry, ASTM D7309-07, 2007.

Standard Test Method for Determining Flammability Characteristics of Plastics and Other Solid Materials Using Microscale Combustion Calorimetry, ASTM D7309-11, 2011.

Standard Test Method for Determining Flammability Characteristics of Plastics and Other Solid Materials Using Microscale Combustion Calorimetry, ASTM D7309-13, 2013.

Lyon RE, Walters RN. Pyrolysis combustion flow calorimetry. J Anal Appl Pyrol. 2004;71:27–46.

Lyon RE, Safronava N, Senes J, Stoliarov SI. Thermokinetic model of sample response in nonisothermal analysis. Thermochimi Acta. 2012;545:82–9.

Lyon RE, Walters RN, Stoliarov SI, Safronava N. Principles and practice of microscale combustion calorimetry, DOT/FAA/TC-12/53, April 2013.

Stoliarov SI, Crowley S, Lyon RE, Linteris GT. Prediction of the burning rates of non-charring polymers. Combust Flame. 2009;156:1068–83.

Standard Practice for Use of the Terms Precision and Bias in ASTM Test Methods, ASTM E177-14, 2014.

Kannan P, Biernacki JJ, Visco DP Jr, Lambert W. Kinetics of thermal decomposition of expandable polystyrene in different gaseous environments. J Anal Appl Pyrol. 2009;84:139–44.

Correlation and dependence—Wikipedia, the free encyclopedia.mht. Accessed 20 Jan 2015.

Rhodes BT, Quintiere JG. Burning rate and flame heat flux for PMMA in a cone calorimeter. Fire Safety J. 1996;26:221–40.

Acknowledgements

This research is supported by the National Natural Science Foundation of China, No. 51376093. The research team is honored by “Six Talent Peaks” project of Jiangsu Province, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Q., Jin, C., Griffin, G.J. et al. A PMMA flammability analysis using the MCC. J Therm Anal Calorim 126, 1831–1840 (2016). https://doi.org/10.1007/s10973-016-5688-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5688-z