Abstract

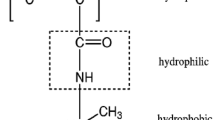

Hydrophilic silica aerogel nanoparticles’ surface was functionalized with 3-(trimethoxysilyl)propyl methacrylate (MPS). Then, the resultant functionalized nanoparticles were used in grafting through copolymerization of styrene and butyl acrylate by simultaneous reverse and normal initiation technique for atom transfer radical copolymerization (SR&NI ATRP) to synthesize tailor-made random poly (styrene-co-butyl acrylate) nanocomposites with twofold chains. Successful surface modification of hydrophilic silica aerogel nanoparticles with MPS is demonstrated by Fourier transform infrared spectroscopy and thermogravimetric analysis (TG). Nitrogen adsorption/desorption isotherm is applied to examine surface area and structural characteristics of the synthesized silica aerogel nanoparticles. Evaluation of size distribution and morphological studies were also performed by scanning and transmission electron microscopy. Conversion and molecular weight determinations were carried out using gas and size exclusion chromatography, respectively. Addition of MPS-functionalized nanoparticles by 3 mass% results in a decrease in conversion from 71 to 46 %. Molecular weight (M n) of the free poly (styrene-co-butyl acrylate) chains decreases by adding 3 mass% MPS-functionalized silica aerogel nanoparticles; however, polydispersity index (PDI) value increases from 1.17 to 1.48. Although PDI values of the attached poly (styrene-co-butyl acrylate) chains are increased from 1.54 to 1.76, M n values reveal an increment by adding silica aerogel nanoparticles. 1H NMR spectroscopy results indicate that the molar ration of each monomer in the copolymer chains is approximately similar to the initial selected mole ratio of the monomers. Increasing thermal stability of the nanocomposites is demonstrated by TG. Differential scanning calorimetry also shows a decrease in glass transition temperature by increasing modified silica aerogel nanoparticles.

Similar content being viewed by others

References

Fu X, Qutubuddin S. Polymer. 2001;42:807–13.

Li X, Huang C, Yang H, Li Y, Cheng Y. J Therm Anal Calorim. 2016;124:899–907.

Hasan M, Kumar R, Barakat MA, Lee M. RSC Adv. 2015;5:14393–9.

Wei L, Hu N, Zhang Y. Materials. 2010;3:4066.

Nguyen Q, Baird D. Adv Polym Technol. 2006;25:270–85.

Malucelli G, Alongi J, Gioffredi E, Lazzari M. J Therm Anal Calorim. 2013;111:1303–10.

Ribeiro T, Baleizão C, Farinha JPS. Materials. 2014;7:3881–900.

Ji X, Hampsey JE, Hu Q, He J, Yang Z, Lu Y. Chem Mater. 2003;15:3656–62.

Khezri K, Haddadi-Asl V, Roghani-Mamaqani H. NANO 2014; 9, Art Number: 1450023.

Cabanas A, Enciso E, Carbajo MC, Torralvo MJ, Pando C, Renuncio JAR. Chem Mater. 2005;17:6137–45.

Logar NZ, Kaučič V. Acta Chim Slov. 2006;53:117–35.

Zhang J, Grischkowsky D. J Phys Chem B. 2004;108:18590–600.

Davis ME. Nature. 2002;417:813–21.

Wei T, Lu S, Chang Y. J Phys Chem B. 2008;112:11881–6.

Bandi S, Bell M, Schiraldi DA. Macromolecules. 2005;38:9216–20.

Hwang S-W, Kim T-Y, Hyun S-H. Microporous Mesoporous Mater. 2010;130:295–302.

Dunn BC, Cole P, Covington D, Webster MC, Pugmire RJ, Ernst RD, Eyring EM, Shah N, Huffman GP. Appl Catal A Gen. 2005;278:233–8.

Rao AV, Kulkarni MM, Amalnerkar DP, Seth T. Appl Surf Sci. 2003;206:262–70.

Cha J, Kim S, Park K-W, Lee DR, Jo J-H, Kim S. J Therm Anal Calorim. 2014;116:219–24.

Sarawade PB, Kim J-K, Hilonga A, Kim HT. Sol. State Sci. 2010;12:911–8.

Gelb LD. J Phys Chem C. 2007;111:15792–802.

Tao Y, Endo M, Kaneko K. Rec Pat Chem Eng. 2008;1:192–200.

Braunecker W, Matyjaszewski K. Prog Polym Sci. 2007;32:93–146.

Oh JK. J Polym Sci Part A Polym Chem. 2008;46:6983–7001.

Cunningham MF. Prog Polym Sci. 2008;33:365–98.

Matyjaszewski K, Xia J. Chem Rev. 2001;101:2921–90.

Demirelli K, Kaya E, Coşkun M, Bağci E. J Therm Anal Calorim. 2013;114:917–26.

Bauri K, Roy SG, Arora S, Dey RK, Goswami A, Madras G, De P. J Therm Anal Calorim. 2013;111:753–61.

Sarbu T, Pintauer T, Mckenzie B, Matyjaszewski K. J Polym Sci Part A Polym Chem. 2002;40:3153–60.

Min K, Matyjaszewski K. Cent Eur J Chem. 2009;7:657–74.

Pyun J, Matyjaszewski K. Chem Mater. 2001;13:3436–48.

Ver Meer MA, Narasimhan B, Shanks BH, Mallapragada SK. ACS Appl Mater Interfaces. 2010;2:41–7.

He J, Duan X, Evans DG. J Porous Mater. 2002;9:49–56.

Ding S, Liu B, Zhang C, Wu Y, Xu H, Qu X, Liu J, Yang Z. J Mater Chem. 2009;19:3443–8.

Lowes BJ, Bohrer AG, Tran T, Shipp DA. Polym Bull. 2009;62:281–9.

Sarsabili M, Parvini M, Salami-kalajahi M, Ganjeh-anzabi P. Adv Polym Technol. 2013;32:21372–83.

Li Z, Zhang K, Ma J, Cheng C, Wooley KL. J Polym Sci Part A Polym Chem. 2009;47:5557–63.

Boday DJ, Keng PY, Muriithi B, Pyun J, Loy DA. J Mater Chem. 2010;20:6863–5.

Sobani M, Haddadi-Asl V, Salami-Kalajahi M, Roghani-Mamaqani H, Mirshafiei-Langari S-A, Khezri K. J Sol–Gel Sci Technol. 2013;66:337–44.

Chen-Yang YW, Wang YL, Chen YT, Li YK, Chen HC, Chiu HY. J Power Sources. 2008;182:340–8.

Boday DJ, Stover RJ, Muriithi B, Keller MW, Wertz JT, Obrey KAD, Loy DA. ASC Appl Mater Interfaces. 2009;1:1364–9.

Costela A, Moreno IG, Gómez C, García O, Sastre R, Roig A, Molins E. J Phys Chem B. 2005;109:4475–80.

Khezri K, Haddadi-Asl V, Roghani-Mamaqani H, Salami-Kalajahi M. J Appl Polym Sci. 2012;124:2278–86.

Khezri K, Haddadi-Asl V, Roghani-Mamaqani H, Salami-Kalajahi M. Polym Compos. 2011;32:1979–87.

Mirshafiei-Langari S, Haddadi-Asl V, Roghani-Mamaqani H, Sobani M, Khezri K. Polym Compos. 2013;34:1648–54.

Mirshafiei-Langari S-A, Haddadi-Asl V, Roghani-Mamaqani H, Sobani M, Khezri K. J Polym Res. 2013;20:163–74.

Xi J, Qiu X, Zhu W, Tang X. Microporous Mesoporous Mater. 2006;88:1–7.

Tang W, Matyjaszewski K. Macromol Theory Simul. 2008;17:359–75.

Min K, Li M, Matyjaszewski K. J Polym Sci Part A Polym Chem. 2005;43:3616–22.

Li M, Min K, Matyjaszewski K. Macromolecules. 2004;37:2106–12.

Li M, Jahed NM, Min K, Matyjaszewski K. Macromolecules. 2004;37:2434–41.

Roghani-Mamaqani H, Haddadi-Asl V, Najafi M, Salami-Kalajahi M. Polym Compos. 2010;31:1829–37.

Roghani-mamaqani H, Haddadi-Asl V, Najafi M, Salami-kalajahi M. AIChE J. 2011;57:1873–81.

Khezri K, Roghani-Mamaqani H, Sarsabili M, Sobani M, Mirshafiei-Langari S. Polym Sci Ser B. 2014;56:909–18.

Samakande A, Sanderson RD, Hartmann PC. J Polym Sci Part A Polym Chem. 2008;46:7114–26.

Sarsabili M, Parvini M, Salami-Kalajahi M, Asfadeh A. Iran Polym J. 2013;22:155–63.

Matyjaszewski K, Qiu J, Tsarevsky NV, Charleux B. J Polym Sci Part A Polym Chem. 2000;38:4724–34.

Asfadeh A, Haddadi-Asl V, Salami-Kalajahi M, Sarsabili M, Roghani-Mamaqani H. Nano 2013;8, Art Number: 1350018.

Ahmadian-Alam L, Haddai-Asl V, Roghani-Mamaqani H, Hatami L, Salami-Kalajahi M. J Polym Res. 2012;19:9773–85.

Khezri K, Haddadi-Asl V, Roghani-Mamaqani H, Salami-Kalajahi M. J Polym Eng. 2012;32:111–9.

Subramania S, Choia SW, Lee JY, Kim JH. Polymer. 2007;48:4691–703.

Sobani M, Haddadi-Asl V, Mirshafiei-Langari S-A, Salami-Kalajahi M, Roghani-Mamaqani H, Khezri K. Des Monomers Polym. 2014;17:245–54.

Khezri K, Roghani-Mamaqani H. Mater Res Bull. 2014;59:241–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarsabili, M., Kalantari, K. & Khezri, K. SR&NI atom transfer radical random copolymerization of styrene and butyl acrylate in the presence of MPS-functionalized silica aerogel nanoparticles. J Therm Anal Calorim 126, 1261–1272 (2016). https://doi.org/10.1007/s10973-016-5641-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5641-1