Abstract

The increasing attractiveness of the adsorption methods of CO2 capturing from coal power plant flue gas, which can be observed in recent years, is linked directly with the appearance and development of new, efficient CO2 adsorbents. The success of an adsorbent depends on the development of the material that, under flue gas temperature conditions, will have high sorption capacity and selectivity for CO2. At the same time, the ease of regeneration and the usable lifetime of the adsorbent are of key importance. The paper presents the potential of metal–organic frameworks (MOFs) for VPSA method for flue gas CO2 capture. In this study, the thermogravimetric test has been used to screen two kind of MOFs [CuBTC, MIL-53(Al)] and identification of promising materials for CO2 capture. The examination of the sorption capacity, stability and regeneration performance of metal–organic frameworks was carried out using a Mettler TGA/SDTA 851e thermobalance and TG-Vacuum system. The studies of adsorption/desorption on the MOFs showed complete desorption of CO2, which confirmed the reversible nature of the process and the ability to use in multiple cycles in VPSA unit.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The increasing attractiveness of the VPSA (Vacuum Pressure Swing Adsorption) method of CO2 capturing from coal power plant flue gas (compared to the preferred currently absorption methods), which can be observed in recent years, is linked directly with the appearance of new, efficient CO2 adsorbents such as metal–organic frameworks (MOFs) [1]. The most important step in the design of a VPSA plant—cycles—is the selection of the adsorbent. To be used in the VPSA adsorption method, an ideal adsorbent should exhibit not only high selectivity and sorption capacity with respect to CO2 but also easy regeneration and stability during extensive adsorption–desorption cycling. Currently, only activated carbons and zeolites can be used for a large-scale VPSA units [2–4]. The metal–organic frameworks (MOFs) are a new class of nanoporous solids proposed to be used in adsorption VPSA units [5]. Metal–organic frameworks, MOFs, are considered for CO2 capture owing to their large specific surface area (of up to 6240 m2/g), ordered pore structure and large pore volume [5, 6]. The majority of MOFs exhibit high sorption capacity with respect to CO2 in a higher pressure range (of up to 42 bar), thus excelling other physical adsorbents, such as zeolites and activated carbons. In turn, the heat needed for the desorption of CO2 from these compounds is significantly lower than that of zeolites.

Unfortunately, in the range of lower pressures (typical of flue gas), only selected MOFs exhibit the adequate sorption properties with respect to CO2. Among the whole range of MOFs especially recommended for CO2 capture is CuBTC (copper benzene-1,3,5-tricarboxylate). CuBTC was used by Raganati et al. [7] on a laboratory scale for CO2 capture on a fluidized bed. The key parameter of MOFs, which determined their application potential, is porosity and particularly the diameter of the largest nanopore. The larger the nanopore diameter, the easier access by the adsorbed substance to the inner space. Among MOFs, the largest nanopore diameters are exhibited by, e.g., MIL-53 frameworks. This metal–organic structure is also characterized by the highest pore homogeneity. This is one of the reasons why these MOFs were selected for the evaluation of the potential of its use in the VPSA gas stream CO2 separation installation. Due to very high sorption capacity of some MOFs compared to zeolites, these compounds are mentioned as potentially the best adsorbents for VPSA systems. A limitation is the lack of knowledge regarding the behavior of these compounds in actual VPSA systems and a considerable cost at the present stage of their development [5–7].

The regenerability and cyclic stability of adsorbents are among the most important characteristics taken into consideration when looking for CO2 efficient adsorbents. It is essential that the adsorbent does not decrease in its sorption capacity during multiple adsorption–desorption cycles and does not change in its structure and properties.

The ease of adsorbent regeneration is one of the key parameters in choosing the adsorbent for an adsorption CO2 capture plant. To be useful for applications in multistage cycles, the adsorbent should be regenerable, while not losing its sorption properties. Depending on the structural and chemical properties of the adsorbent, the adsorption–desorption cycling can be carried out by changing the temperature and/or pressure (or vacuum). Therefore, the most suitable adsorbent needs to be selected for respective adsorption processes (TSA, PSA, VSA, PTSA). The stability of the adsorbent during extensive adsorption–desorption cycling is another parameter in its selection for adsorption CO2 capture installations. The stability is the key parameter of an adsorbent, as it determines its life and thus the frequency of its replacement in the adsorption plant. The life of adsorbents is therefore equally important as their CO2 sorption capacity, selectivity or kinetics, because it directly influences the economy of the process of CO2 capture by the adsorption method and the possibility of using the adsorbents on a commercial scale.

The sorption capacity, regenerability and sorbent stability in multiple cycles can be determined using thermogravimetric methods (a TGA/SDTA 851e analyzer and TG-Vacuum system), which are commonly used for assessing the sorption capacity of adsorbent samples with respect to CO2. The TG-Vacuum system is used as a straightforward, fast laboratory method enabling the evaluation of the regeneration performance of materials and the determination of their suitability for CO2 separation in VPSA units.

The aim of this study was comparison of regeneration performance of two metal–organic frameworks (MOFs) proposed for VPSA adsorption method for flue gas CO2 capture. The evaluation of sorption capacity and sorbent regeneration in TG-Vacuum system was used to obtain preliminary information about the usefulness of MOFs for use in VPSA installations.

Experimental

Characterization of the adsorbents

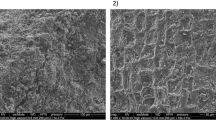

Two types of MOFs were used in test: CuBTC (Basolite C300 produced by BASF) and MIL-53(Al) (Basolite A100 produced by BASF). The metal–organic frameworks [CuBTC and MIL-53(Al)] were characterized by nitrogen adsorption–desorption, TG and SEM analysis. The porous properties of the adsorbents were investigated by determining their N2 gas adsorption and desorption isotherms at −196.15 °C, using an ASAP 2010 Instrument (Micromeritics). The specific surface area was calculated by the BET method from the linear part of BET plot according to IUPAC recommendations using the adsorption isotherm (relative pressure (p/p o) = 0.05–0.23). The pore size distribution was calculated by the BJH method, and the pore volume was obtained from the maximum amount of adsorption at p/p o of 0.99. The microstructures of the adsorbents were observed using an Electron Microscopes (EVO-40 Series, Carl Zeiss SMT).

Thermogravimetric test

The examination of the sorption capacity, regenerability and stability solid adsorbents, including CuBTC and MIL-53(Al), was carried out using a Mettler TGA/SDTA 851e thermobalance and TG-Vacuum system (Fig. 1). TG-Vacuum system is an innovative combination of thermogravimetric methods and vacuum pump properties in one device. The main element of TG-Vacuum System is TGA/SDTA 851e thermobalance (TG). To work in VPSA simulated system, unit has been retrofitted with specially selected Vacuum system. Vacuum system consist vacuum pump, valves–vent valve, the gas trap, cryogenic trap and vacuum controller. Preliminary evaluation of sorption capacity and sorbent regeneration in TG-Vacuum system is used to obtain information about the usefulness of sorbents for use in VPSA installations.

The proposed CO2 thermogravimetric test utilizes the following temperature program.

Adsorbent thermal stability test (TST)

The thermal properties of the metal–organic frameworks were characterized by a thermogravimetric analysis (TG). The TG was performed on a Mettler TGA/SDTA 851e thermobalance. About 10 mg of the sample was heated at 20 °C min−1 to 1000 °C in nitrogen flow (50 mL min−1). The samples were heated in a platinum crucible.

Isothermal adsorption test (IAT)

In the isothermal test, sorbent samples were heated from 25 to 100 or 200 °C in a nitrogen atmosphere (with a heating rate of 10 °C min−1) and held at this temperature for 30 min (until a constant sample mass was achieved). Then, the CO2 sorption process was conducted isothermally (at a temperature of 30 °C), being held at that temperature until an equilibrium state was attained, under atmospheric pressure, using 100 % pure (more specifically, 99.998 %) CO2 at a flow rate of 50 cm3 min−1. This method is commonly used for the evaluation of the maximum equilibrium capacity (the differences relate to varying adsorption time—depending on the type of adsorbents—and the gas flow rate applied).

Cyclic adsorption–desorption test (CADT)

In order to determine the cyclic stability of adsorbents, multistage CO2 adsorption–desorption cycles were carried out. In the cyclic adsorption–desorption test, the pure CO2 was passed for a period of 15 min, at a temperature of 30 °C. Based on the mass increment occurred during this stage, the CO2 sorption capacity at this temperature was determined. After completion of the CO2 sorption process, a desorption process was carried out. For the regeneration of the adsorbent, a vacuum was employed (10 kPa abs.). The sorption/desorption cycles were repeated five times in a continuous manner. The duration of a single sorption/desorption cycle for sorbents was 30 min. The gas flow rate was set at 50 cm3 min−1.

Results

Characterization of the adsorbents

Table 1 gives the textural parameters of the CuBTC and MIL-53(Al). As follows from Table 1, the BET surface area for CuBTC (774.9 m2 g−1) is greater than BET surface area for MIL-53(Al) (299.33 m2 g−1). The pore volume for CuBTC (0.35 cm3 g−1) is also greater than pore volume for MIL-53(Al) (0.22 cm3 g−1).

Figure 2 shows adsorption isotherms for the CuBTC and MIL-53(Al). The adsorption isotherm for the CuBTC is an isotherm of type I, which indicates its ordered microporous structure (none hysteresis loop) [8]. In the case of MIL-53 (Al), we can notice an isotherm of type IV exhibiting a hysteresis loop, which is associated with capillary condensation in mesopores [8, 9].

Figure 3a, b show a SEM photographs of CuBTC and MIL-53(Al). The SEM images of the samples show that the crystals of MOFs are in the shape of an octahedron. The particle size was 2–30 μm [8, 9].

Thermogravimetric CO2 test

Thermal stability

Figure 4 shows the thermal decomposition of two types of as-synthesized MOFs such as CuBTC·nH2O (Fig. 4a) and MIL-53(Al)·nH2O (Fig. 4b) in an inert atmosphere (N2). As indicated by the TG curves (Fig. 4), two mass losses are noticeable in both samples. The first mass loss is due to the desorption of water and amounts to approx. 17 % for CuBTC·nH2O and 9 % for MIL53(Al)·nH2O. The second mass loss in both samples results from the decomposition of the organic part of MOFs and amounts to about 56 % for CuBTC·nH2O and 60 % for MIL53(Al)·nH2O. Based on the TG/DTG curves, it is also possible to determine the MOFs decomposition temperature, which for CuBTC·nH2O and MIL53(Al)·nH2O is, respectively, 300 and 500 °C.

Sorption capacity

Figure 5 shows the results of the isothermal CO2 adsorption test for the CuBTC and MIL-53(Al) (100 vol.% CO2). At the temperature 30 °C, CuBTC had the sorption of capacity at a level of 160 mg CO2 g−1 adsorbent, that is 3 times higher than MIL-53(Al). The differences in CO2 sorption capacity between the two examined types of MOFs might be due to the differences in their pore size and geometry. The high affinity of CO2 molecules in CuBTC results from its 3D microporous structure and the direct interaction of CO2 molecules with the unsaturated copper ions of the metallic cluster. In the case of MIL-53(Al), which has a 1D porous structure, the CO2 adsorption is associated with the interaction of CO2 molecules with the µ2-OH groups [10]. The obtained results confirm the high sorption capacity of the metal–organic frameworks (MOFs) under working pressure conditions, compared to common adsorbents, such as zeolites and activated carbons [3, 4].

Assessment of adsorbent regenerability in multistage cycles

Figure 6 presents adsorption–desorption profiles for metal–organic frameworks (CuBTC and MIL-53(Al) in consecutive CO2 adsorption–desorption. The sorption/desorption cycles were repeated 5 times. The duration of a single sorption/desorption cycle for metal–organic frameworks was 30 min. As follows from Fig. 6, metal–organic frameworks exhibited very good cyclicity and fastness during the course of the entire experiment. The CuBTC had a higher adsorption rate and a constant maximum sorption capacity after five cycles. The monotonous shift during the cycling, visible in Fig. 6, results from the conditions of sample stabilization in the TG-Vacuum system.

As follows from Fig. 6, repeated using of the adsorbent does not cause any noticeable reduction in its adsorption capacity, which obviously confirms the good stability of the adsorbent and the possibility of using it in subsequent cycles. This feature is very important from the point of view of the practical use of the adsorbent in many CO2 sorption/desorption cycles. The desorption capacity for the adsorbent tested was 100 %. The desorption process shows a relatively rapid desorption process and no CO2 seems to remain adsorbed at the end of the experiment. As can be observed, the working capacity of both adsorbents in each cycle is the same. A stable state of adsorbent operation with the use of pure CO2 occurs already after the second cycle. MIL-53(Al) attains then an active sorption capacity of about 55 mg CO2 g−1 adsorbent, while CuBTC attains active sorption capacity at a level of approx. 90 mg CO2 g−1 adsorbent. The preliminary assessment of the MOFs in the TG-Vacuum simulated vacuum system has confirmed the capability of the adsorbents to work in a pressure swing adsorption system, while indicating the need for further investigation.

Conclusions

The research of CO2 adsorption on metal–organic frameworks carried out within this work has shown that these materials are characterized by high CO2 adsorption capacity and have the chance of becoming an efficient adsorbent for application to post-combustion CO2 separation. The studies of adsorption–desorption on the adsorbents showed complete desorption of CO2, which confirmed the reversible nature of the process and the ability to use in multiple cycles in VPSA unit.

The thermogravimetric test for testing solid CO2 adsorbents proposed in the article may provide a helpful tool for preliminary testing of porous materials and establishing their CO2 adsorption potential. The TG-Vacuum test is simple and fast, which enables valuable information to be obtained in a short time. Moreover, complementing the data obtained from the CO2 thermogravimetric test with additional analyses (adsorption equilibrium isotherms) enables the assessment of the quality of the adsorbent and its potential prior to the tests in laboratory and pilot adsorption units, such as the VPSA or TSA. In the light of the immense development of solid CO2 adsorbents that has been occurring in recent years, the preselection of adsorbents requires efficient and straightforward tests to be used, which make it possible to tentatively assess their CO2 removal potential prior to further tests.

References

Sabouni R, Kazemian H, Rohani S. Carbon dioxide capturing technologies: a review focusing on metal organic framework materials (MOFs). Environ Sci Pollut Res. 2014;21:5427–49.

Webley PA. Adsorption technology for CO2 separation and capture: a perspective. Adsorption. 2014;20:225–31.

Bukalak D, Majchrzak-Kucęba I, Nowak W. Assessment of the sorption capacity and regeneration of carbon dioxide sorbents using thermogravimetric methods. J Therm Anal Calorim. 2013;113:157–60.

Krishnamurthy S, Rao VR, Guntuka S, Sharratt P, Haghpanah R, Rajendran A, Amanullah M, Karimi IA, Farooq S. CO2 capture from dry flue gas by vacuum swing adsorption: a pilot plant study. AIChE J. 2014;5:1830–42.

Chen Ch, Kim J, Ahn WS. CO2 capture by amine-functionalized nanoporous materials: a review. Korean J Chem Eng. 2014;31:1919–34.

Sabouni R, Kazemian H, Rohani S. Carbon dioxide capturing technologies: a review focusing on metal organic framework materials (MOFs). Environ Sci Pollut Res. 2014;21:5427–49.

Raganaty F, Gargiulo V, Ammendola P, Alfe M, Chirone R. CO2 capture performance of HKUST-1 in a sound assisted fluidized bed. Chem Eng J. 2014;239:75–86.

Zhang H, Xiao R, Song M, Shen D, Liu J. Hydrogen production from bio-oil by chemical looping reforming. Characteristics of the synthesized metal organic frameworks for CO2 removal. J Therm Anal Calorim. 2014;115:1921–7.

Ye S, Jiang X, Ruan L-W, Liu B, Wang Y-M, Zhu J-F, Qiu L-G. Post-combustion CO2 capture with the HKUST-1 and MIL-101(Cr) metal–organic frameworks: adsorption, separation and regeneration investigations. Microporous Mesoporous Mater. 2013;179:191–7.

Martinez F, Sanz R, Orcajo G, Briones D, Yanguez V. Amino-impregnated MOF materials for CO2 capture at post-combustion conditions. Chem Eng Sci. 2016;142:55–61.

Acknowledgements

The research leading to these results has received funding from the Polish-Norwegian Research Programme operated by the National Centre for Research and Development under the Norwegian Financial Mechanism 2009–2014 in the frame of Project Contract No. Pol-Nor/211319/8/2013. The research leading to these results has received funding from the People Programme (Marie Curie Actions) of the European Union’s Seventh Framework Programme FP7/2007–2013/under REA Grant Agreement No. PIRSES-GA-2013-612699.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Majchrzak-Kucęba, I., Bukalak-Gaik, D. Regeneration performance of metal–organic frameworks. J Therm Anal Calorim 125, 1461–1466 (2016). https://doi.org/10.1007/s10973-016-5624-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5624-2