Abstract

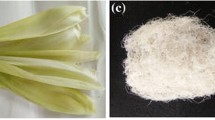

The conventional cellulose nitrate (NC), used in many applications such as coating agent, main charge of propellant, museum artefacts, biofilter material, solid-phase immobilization supports for proteins, was mainly prepared from wood or cotton. The conventional NC presents many drawbacks such as low density, high friability and low combustion temperature. One approach to improve these shortcomings is the modification of the structure of the NC precursor (cellulose). In this work, microcrystalline cellulose nitrate was successfully produced from an inexpensive and easily renewable source which is Alfa grass. Fourier transform infrared spectroscopy indicates some modifications in the peak positions and intensities, suggesting that a significant difference between conventional and microcrystalline cellulose nitrate samples exists. According to X-ray diffraction results, microcrystalline cellulose nitrate samples were more crystalline than the conventional cellulose nitrate samples, where the increase of the crystallinity is 22 %. The morphology was investigated using scanning electron microscopy, showing a compact structure and a rough surface. In comparison with the commercial nitrocellulose material, the microcrystalline cellulose nitrate particles have good thermal stability, low viscosity, high nitrogen content and important quantity of gas released. Besides on these results, Alfa microcrystalline cellulose nitrate showed tremendous potential use as a propellant and gas generator component or other high value-added applications.

Similar content being viewed by others

References

Pappu A, Patil V, Jain S, Mahindrakar A, Haque R, Thakur VK. Advances in industrial prospective of cellulosic macromolecules enriched banana biofibre resources: a review. Int J Biol Macromol. 2015;79:449–58.

Thakur VK, Thakur MK. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr Polym. 2014;109:102–17.

Thakur VK, Thakur MK. Recent advances in graft copolymerization and applications of Chitosane: a review. ACS Sustain Chem Eng. 2014;2(12):2637–52.

Thakur VK, Singha AS. KPS-initiated graft copolymerization onto modified cellulosic biofibers. Int J Polym Anal Charact. 2014;15:471–85.

Thakur VK, Kessler MR. Self-healing polymer nanocomposites materials: a review. Polymer. 2015;69:369–83.

García-Fayos P, Gasque M. Seed vs. microsite limitation for seedling emergence in the perennial grass Stipatenacissima L. (Poaceae). Acta Oecol. 2006;30:276–82.

Trache D, Donnot A, Khimeche K, Benelmir R, Brosse N. Physico-chemical properties and thermal stability of microcrystalline cellulose isolated from Alfa fibres. Carbohydr Polym. 2014;104:223–30.

Bessadok A, Marais S, Gouanve F, Colasse L, Zimmerlin I, Roudesli S, et al. Effect of chemical treatments of Alfa (Stipatenacissima) fibres on water-sorption properties. Compos Sci Technol. 2007;67:685–97.

Maafi EM, Malek F, Tighzert L, Dony P. Synthesis of polyurethane and characterization of its composites based on Alfa cellulose fibers. J Polym Environ. 2010;18:638–46.

Moniruzzaman M, Bellerby JM, et Bohn MA. Activation energies for the decomposition of nitrate ester groups at the anhydroglucopyranose ring positions C2, C3 and C6 of nitrocellulose using the nitration of a dye as probe. Polym Degrad Stab. 2014;102:49–58.

Jin M, Luo N, Li, G, Luo Y. The thermal decomposition mechanism of nitrocellulose aerogel. J Therm Anal Cal. 2015. doi:10.1007/s10973-015-4574-4.

Fernández de la Ossa MA, López-López M, Torre M, García-Ruiz C. Analytical techniques in the study of highly-nitrated nitrocellulose. Trends Anal Chem. 2011;30:1740–55.

López-López M, Fernández de la Ossa MA, Galindo JS, Ferrando JL, Vega A, Torre M, et al. New protocol for the isolation of nitrocellulose from gun powders: utility in their identification. Talanta. 2010;81:1742–9.

López-López M, Alegre JMR, García-Ruiz C, Torre M. Determination of the nitrogen content of nitrocellulose from smokeless gunpowders and collodions by alkaline hydrolysis and ion chromatography. Anal Chim Acta. 2011;685:196–203.

Trache D, Khimeche K, Benelmir R, Dahmani A. DSC measurement and prediction of phase diagrams for binary mixtures of energetic materials’ stabilizers. Thermochim Acta. 2013;565:8–16.

Trache D, Khimeche K, Benziane M, Dahmani A. Solid–liquid phase equilibria for binary mixtures of propellant’s stabilizers. J Therm Anal Cal. 2013;112:215–22.

Trache D, Khimeche K. Study on the influence of ageing on chemical and mechanical properties of N, N’-dimethyl-N, N’-diphenylcarbamide stabilized propellants. J Therm Anal Cal. 2013;111:305–12.

Princi E, Vicini S, Marsano E, Trefiletti V. Influence of the artificial weathering on thermal stability of paper based materials. Thermochim Acta. 2008;468:27–34.

Roberts JC. The chemistry of paper. The Royal Society of Chemistry, 1996. p. 21.

Yang FF, Shao Z, Li NK, Wang FJ, Zhang Y. A novel cellulose-based azide energetic material: 1-azido-2-hydroxypropyl cellulose ether. J Energ Mater. 2011;29(3):241–60.

Nickel RR, Wlker RR. Method for manufacture of microcrystalline nitrocellulose. US patent, 2006.0180253 A1.

Betzler FM, Klapötke TM, Sproll S. Energetic nitrogen-rich polymers based on cellulose. Cent Eur J Energ Mater. 2011;8(3):157–71.

Shamsipur M, Pourmortazavi SM, Hajimirsadeghi SS, Atifeh SM. Effect of functional group on thermal stability of cellulose derivative energetic polymers. Fuel. 2012;95:394–9.

Pourmortazavi SM, Sadri M, Rahimi-Nasrabadi M, Shamsipur M, Jabbarzade Y, Khalaki MS, et al. Thermal decomposition kinetics of electrospun azidodeoxy cellulose nitrate and polyurethane nanofibers. J Therm Anal Cal. 2014. doi:10.1007/s10973-014-4064-0.

Nickel RR. Microcrystalline nitrocellulose pyrotechnic compositions. US Patent, 2007.0068610 A1.

Cheng HN, Dowd MK, Selling GW, Biswas A. Synthesis of cellulose acetate from cotton byproducts. Carbohydr Polym. 2010;80:449–52.

Urbansky T. Chemistry and technology of explosives. London: Pergamon Press; 1965. p. 213–413.

Moore JA. Macromolecular syntheses: collective volume, Vol. 1. New York: Wiley Ltd.; 1977. p. 363–6.

Lin CP, Shu CM. A comparison of thermal decomposition energy and nitrogen content of nitrocellulose in non-fat process of linters by DSC and EA. J Therm Anal Cal. 2009;95(2):547–52.

Wu Y, Ge Z, Luo Y. Properties and application of a novel type of glycidyl azide polymer modified double-base spherical powders. J Therm Anal Cal. 2015. doi:10.1007/s10973-015-5122-y.

Zhang X, Weeks BL. Preparation of sub-micron nitrocellulose particles for improved combustion behaviour. J Hazard Mater. 2014;268:224–8.

Dennis LM. Gaz analysis. New York: Macmillan & Co.; 1913.

Eremeeva TE, Bykova TO, Gromov VS. Problems in the size-exclusion chromatography of cellulose nitrates: non-exclusion effects and universal calibration. J Chromatogr A. 1990;522:67–75.

Kim ST, Lim JY, Choi HJ, Hyun H. Solution characteristics of nitrocellulose. J Ind Eng Chem. 2006;12(1):161–4.

Meiling Y, Dong H, Lianghe S. A new type low shear rate viscometer for high molecular weight polymer. Chin J Polym Sci. 1996;14(4):311–7.

Moniruzzaman M, Bellerby JM, Mai N. The effect of light on the viscosity and molecular mass of nitrocellulose. Polym Degrad Stab. 2011;96:929–35.

Quye A, Littlejohn D, Pethrick RA, Stewart RA. Investigation of inherent degradation in cellulose nitrate museum artefacts. Polym Degrad Stab. 2011;96(7):1369–76.

Berthumeyrie S, Collin S, Bussiere PO, Therias S. Photooxidation of cellulose nitrate: new insights into degradation mechanisms. J Hazard Mater. 2014;272:137–47.

Kazemi A, Hayaty M, Mousaviazar A, Samani KY, Keshavarz MH. The synthesis and characterization of polyvinyl nitrate as an energetic polymer and study of its thermal behavior. J Therm Anal Cal. 2014. doi:10.1007/s10973-014-4173-9.

Krouit M, Bras J, Belgacem MN. Cellulose surface grafting with polycaprolactone by heterogeneous click-chemistry. Eur Polym J. 2008;44(12):4074–81.

Kalita RD, Nath Y, Ochubiojo ME, Buragohain AK. Extraction and characterization of microcrystalline cellulose from fodder grass; Setaria glauca (L) P. Beauv, and its potential as a drug delivery vehicle for isoniazid, a first line antituberculosis drug. Colloid Surface B. 2013; 108:85–9.

Milltown RMB, Dover WHG. Nitrocellulose product and method of manufacture of propellant grains employing same. US Patent No. 3,422,169. Washington. 1969.

Kraemer EO. Molecular weights of celluloses and cellulose derivates. Ind Eng Chem. 1938;30(10):1200–3.

Daňhelka J, Kössler I, Boháčková V. Determination of molecular weight distribution of cellulose by conversion into tricarbanilate and fractionation. J Polym Sci Polym Chem. 1976;14(2):287–98.

Kačík F, Kačíková D, Jablonský M, Katuščák S. Cellulose degradation in newsprint paper ageing. Polym Degrad Stab. 2009;94(9):1509–14.

Wagner HL. The Mark–Houwink–Sakurada Equation for the viscosity of linear polyethylene. J Phys Chem Ref Data. 1985;14(2):611–7.

Ratanakamnuan U, Atong D, Aht-Ong D. Cellulose esters from waste cotton fabric via conventional and microwave heating. Carbohydr Polym. 2012;87(1):84–94.

Kovalenko VI. Inhomogeneity in the molecular structure of cellulose nitrates. Russ Chem Rev. 1995;64(8):753–66.

Herrmann M, Förter-Barth U, Mauß JB, Bohn M. Microstructure of nitrocellulose investigated by X-ray diffraction. In: Proceedings 42nd international annual conference of ICT on energetic materials; June 26 to 29, 2011. p. 53/1–7.

Vaughan BR, Higginbotham Z, Mangalam A, Ben’Ous L, Bonnett P. Laboratory scale nitration of cellulose as a cost effective risk mitigation tool for the production of nitrocellulose at Radford Army Ammunition Plant. In: Proceedings insensitive munitions and energetic materials technology symposium, Tucson, AZ, 2009. p. 12.

Miles FD. The molecular aggregation of nitrocellulose. Trans Faraday Soc. 1933;29(140):110–21.

Short RD, Munro HS. Conclusions drawn from a study of cellulose nitration in technical mixed acids by X-ray photoelectron spectroscopy and 13C nuclear magnetic resonance. Polym. 1993;34(13):2714–9.

Yu J, Wu Y, Wang S, Ma X. The preparation of cellulose nitrate derivatives and their adsorption properties for creatinine. Carbohydr Polym. 2007;70(1):8–14.

Nishiyama Y, Johnson GP, French AD. Diffraction from nonperiodic models of cellulose crystals. Cellulose. 2012;19(2):319–36.

Freire CSR, Silvestre AJD, Neto CP, Belgacem MN, Gandini A. Controlled heterogeneous modification of cellulose fibers with fatty acids: effect of reaction conditions on the extent of esterification and fiber properties. J Appl Polym Sci. 2006;100(2):1093–102.

Poletto M, Pistor V, Zeni M, Zattera AJ. Crystalline properties and decomposition kinetics of cellulose fibers in wood pulp obtained by two pulping processes. Polym Degrad Stab. 2011;96:679–85.

Rodrigues Filho G, da Cruz SF, Pasquini D, Cerqueira D, Prado VD, Assuncao RMN. Water flux through cellulose triacetate films produced from heterogeneous acetylation of sugar cane bagasse. J Membr Sci. 2000; 177 (1–2): 225–31.

Pourmortazavi SM, Hosseini SG, Rahimi-Nasrabadi M, Hajimirsadeghi SS, Momenian H. Effect of nitrate content on thermal decomposition of nitrocellulose. J Hazard Mater. 2009;162:1141–4.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Trache D, Khimeche K. Study on the influence of ageing on thermal decomposition of double-base propellants and prediction of their in-use time. Fire Mater. 2013;37:328–36.

Sunitha M, Reghunadhan Nair CP, Krishnan K, Ninan KN. Kinetic of aldre-ene reaction of tris(2-allylphenoxy)triphenoxycyclotriphosphazene and bismaleimides: dSC study. Thermochim Acta. 2001;374:159–69.

Rychly J, Lattuati-Derieux A, Matisova-Rychla L, Csomorova K, Janigova I, Lavédrine B. Degradation of aged nitrocellulose investigated by thermal analysis and chemiluminescence. J Therm Anal Cal. 2012;107:1267–76.

Wang H, Zhang H, Hu R, Yao E, Guo P. Estimation of the critical rate of temperature rise for thermal explosion of nitrocellulose using non-isothermal DSC. J Therm Anal Cal. 2014;115:1099–110.

Abusaidi H, Ghaieni HR, Pourmortazavi SM, Motaled-Shariati SH. Effect of nitro content on thermal stability and decomposition kinetics of nitro-HTPB. J Therm Anal Cal. 2015. doi:10.1007/s10973-015-5178-8.

Sovizi MR, Hajimirsadeghi SS, Naderizadeh B. Effect of particle size on thermal decomposition of nitrocellulose. J Hazard Mater. 2009;168:1134–9.

Huang MR, Li XG. Thermal degradation of cellulose and cellulose esters. J Appl Polym Sci. 1998;68(2):293–304.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Trache, D., Khimeche, K., Mezroua, A. et al. Physicochemical properties of microcrystalline nitrocellulose from Alfa grass fibres and its thermal stability. J Therm Anal Calorim 124, 1485–1496 (2016). https://doi.org/10.1007/s10973-016-5293-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5293-1