Abstract

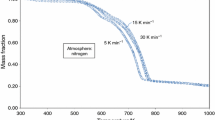

The pyrolysis and combustion of automotive shredder residue (ASR) were studied by dynamic thermogravimetry and derivative thermogravimetry at heating rates of 5, 15 and 30 K min−1 at atmospheric pressure. For the simulation of pyrolysis and combustion processes, two different kinetic models are proposed. One of them is based on the distribution of activation energies (DAEM), with three pools of reactants (three pseudocomponents) because of the complexity of the samples studied. The other model assumes a simple first-order decomposition of the three different fractions. The experimental thermogravimetric data of pyrolysis (oxygen absence) and combustion (at two different oxygen concentrations) processes were simultaneously fitted to determine a single set of kinetic parameters able to describe both processes at the different heating rates. The comparison of the models permits to discuss the importance to consider a DAEM. The experimental results and kinetic parameters may provide useful data for the design of thermal decomposition processing system using ASR as feedstock.

Similar content being viewed by others

References

Gonzalez-Fernandez O, Hidalgo M, Margui E, Carvalho ML, Queralt I. Heavy metals’ content of automotive shredder residues (ASR): evaluation of environmental risk. Environ Pollut. 2008;153(2):476–82. doi:10.1016/j.envpol.2007.08.002.

Santini A, Morselli L, Passarini F, Vassura I, Di Carlo S, Bonino F. End-of-life vehicles management: Italian material and energy recovery efficiency. Waste Manag. 2011;31(3):489–94. doi:10.1016/j.wasman.2010.09.015.

Morselli L, Santini A, Passarini F, Vassura I. Automotive shredder residue (ASR) characterization for a valuable management. Waste Manag. 2010;30(11):2228–34. doi:10.1016/j.wasman.2010.05.017.

Reddy MS, Kurose K, Okuda T, Nishijima W, Okada M. Selective recovery of PVC-free polymers from ASR polymers by ozonation and froth flotation. Resour Conserv Recycl. 2008;52(6):941–6. doi:10.1016/j.resconrec.2008.02.003.

Guo Q, Zhang X, Li C, Liu X, Li J. TG-MS study of the thermo-oxidative behavior of plastic automobile shredder residues. J Hazard Mater. 2012;209–210:443–8. doi:10.1016/j.jhazmat.2012.01.051.

Conesa JA, Font R, Fullana A, Martín-Gullón I, Aracil I, Gálvez A, et al. Comparison between emissions from the pyrolysis and combustion of different wastes. J Anal Appl Pyrolysis. 2009;84(1):95–102.

Rausa R, Pollesel P. Pyrolysis of automotive shredder residue (ASR) influence of temperature on the distribution of products. J Anal Appl Pyrolysis. 1997;40–41:383–401.

Font R, Fullana A, Conesa J. Kinetic models for the pyrolysis and combustion of two types of sewage sludge. J Anal Appl Pyrolysis. 2005;74(1–2):429–38.

Conesa JA, Font R, Fullana A, Caballero JA. Kinetic model for the combustion of tyre wastes. Fuel. 1998;77(13):1469–75.

Conesa JA, Domene A. Biomasses pyrolysis and combustion kinetics through n-th order parallel reactions. Thermochim Acta. 2011;523(1–2):176–81.

Donaj P, Yang W, Blasiak W, Forsgren C, editors. Kinetic study of decomposition of ASR residues after pyrolysis in inert and oxidative atmosphere. In: Joint conference: international thermal treatment technologies (IT3) and hazardous waste combustors (HWC); 2009.

Avni E, Coughlin RW, Solomon PR, King HH. Mathematical modelling of lignin pyrolysis. Fuel. 1985;64(11):1495–501. doi:10.1016/0016-2361(85)90362-x.

Várhegyi G, Szabó P, Jakab E, Till F. Least squares criteria for the kinetic evaluation of thermoanalytical experiments. Examples from a char reactivity study. J Anal Appl Pyrolysis. 2001;57(2):203–22.

Várhegyi G, Bobály B, Jakab E, Chen H. Thermogravimetric study of biomass pyrolysis kinetics. A distributed activation energy model with prediction tests. Energy Fuels. 2011;25(1):24–32.

Conesa JA, Urueña A, Díez D. Corn stover thermal decomposition in pyrolytic and oxidant atmosphere. J Anal Appl Pyrolysis. 2014;106:132–7. doi:10.1016/j.jaap.2014.01.010.

de Jong W, Di Nola G, Venneker BCH, Spliethoff H, Wójtowicz MA. TG-FTIR pyrolysis of coal and secondary biomass fuels: determination of pyrolysis kinetic parameters for main species and NOx precursors. Fuel. 2007;86(15):2367–76. doi:10.1016/j.fuel.2007.01.032.

Caballero JA, Conesa JA. Mathematical considerations for nonisothermal kinetics in thermal decomposition. J Anal Appl Pyrolysis. 2005;73(1):85–100.

Gómez-Rico MF, Martín-Gullón I, Fullana A, Conesa JA, Font R. Pyrolysis and combustion kinetics and emissions of waste lube oils. J Anal Appl Pyrolysis. 2003;68–69:527–46.

Font R, Conesa JA, Molto J, Munoz M. Kinetics of pyrolysis and combustion of pine needles and cones. J Anal Appl Pyrolysis. 2009;85(1–2):276–86.

Aracil I, Font R, Conesa JA, Fullana A. TG-MS analysis of the thermo-oxidative decomposition of polychloroprene. J Anal Appl Pyrolysis 2007;79(1-2 SPEC. ISS.):327–36.

Conesa JA, Moltá J, Font R, Egea S. Polyvinyl chloride and halogen-free electric wires thermal decomposition. Ind Eng Chem Res. 2010;49(22):11841–7.

Conesa JA, Rey L. Thermogravimetric and kinetic analysis of the decomposition of solid recovered fuel from municipal solid waste. J Therm Anal Calorim. 2015;120(2):1233. doi:10.1007/s10973-015-4396-4.

Caballero JA, Conesa JA. New approach to thermal analysis kinetics by considering several first order reactions. Thermochim Acta. 2011;525(1–2):40–9.

Miura K. A new and simple method to estimate f(E) and k0(E) in the distributed activation energy model from three sets of experimental data. Energy Fuels. 1995;9(2):302–7.

Miura K, Maki T. A simple method for estimating f(E) and k0(E) in the distributed activation energy model. Energy Fuels. 1998;12(5):864–9.

Suuberg EM, Peters WA, Howard JB. Product composition and kinetics of lignite pyrolysis. Ind Eng Chem Process Des Dev. 1978;17(1):37–46.

Acknowledgements

Support for this work was provided by the CTQ2013-41006-R project from the Ministry of Economy and Competitiveness (Spain) and the PROMETEOII/2014/007 project from the Valencian Community Government (Spain).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Conesa, J.A., Rey, L. & Aracil, I. Modeling the thermal decomposition of automotive shredder residue. J Therm Anal Calorim 124, 317–327 (2016). https://doi.org/10.1007/s10973-015-5143-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-5143-6