Abstract

The aim of the study was an analysis of two groups of glasses from the SiO2–P2O5–K2O–CaO–MgO system with various content of network formers in the form of P2O5 and SiO2, modified by the addition of ZnO. Their effect on glass-forming ability, glass transition effect, crystallization process and the kind of crystallizing phases was examined using DSC and XRD methods. It was observed that in both matrixes, the addition of ZnO decreases the glass transition temperature (T g). The lower T g values observed in the phosphate matrix glasses and the accompanying higher values of the changes in molar heat capacity (Δc p) in contrast to the silicate matrix glasses may be considered an indicator of the degree of the reconstruction of their amorphous structure, which facilitates the process of their crystallization. It was found that the crystallizing products of the silicate matrix glasses were silicates and phosphates whose structure contained zinc. In the phosphate matrix glasses, it was observed that zinc inhibited the crystallization of silicate phases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Phosphate and silicate glasses containing zinc have been studied intensively, because many of them have been found useful for special applications.

Zinc phosphate glasses have been developed for use as LED light sources [1, 2] and as substrates for optical waveguides written by f-sec lasers [3–6]. Zinc phosphate glasses also tend to have greater coefficients of thermal expansion with low processing temperatures, which makes them useful as sealing glasses [7, 8]. Because zinc is a trace element that plays an important role in bone formation and mineralization [9, 10], zinc-containing glasses and glass ceramics have been developed for bone engineering applications [11–13]. Zinc has also been cited as a useful antibacterial agent in glass-ionomer-based cements [14] and ceramic coatings [15]. Thus, the addition of zinc to various materials and their use in bone tissue engineering may have important implications for appropriate integration into implant sites with minimal bone infection risk, a complication often associated with the repair of skeletal defects.

It is a well-known fact that the ability to absorb components that function as modifiers is much higher in the phosphate matrix glasses than in the silicate matrix glasses. The ability to take the amorphous form also depends on the kind of introduced modifiers [16, 17]. The works [18–20] show that it is possible to add up to 80 mol% of ZnO into the structure of the glasses from the system P2O5–ZnO. Examining the scope of forming silicate glasses modified with ZnO, Kaur et al. [21] produced silicate glass with the composition 40SiO2–30BaO–20ZnO–10B2O3(Al2O3), and Hurt and Philips [22] introduced 35 mol% ZnO into the structure of the glasses from the Na2O–ZnO–SiO2 system. The research done by Minser et al. [23] shows that it is possible to obtain fully amorphous glass from the Na2O–ZnO–SiO2 system if it contains the addition of ZnO in the amount of up to 30 % mol. The research on the glasses with the composition (100−x)SiO2–7CaO–5K2O–19Na2O–xZnO done by Chen et al. [24] indicates that adding over 19 mol% of ZnO causes their crystallization.

There is little information in the literature about the possibility of introducing zinc into the structure of silicate–phosphate glasses. Goel et al. [25] introduced the additive ZnO into the structure of glasses composed of 36.07CaO–(19.24−x)MgO–xZnO–5.61P2O5–38.49SiO2–0.59CaF2, where x ≤ 10 mol%, produced in the traditional melting process, and Aina et al. [26], employing the same method for the synthesis, obtained fully amorphous glass containing 20.2 mass% ZnO and 37.3 % SiO2, 18.8 % Na2O, 18.9 % CaO, 4.5 % P2O5 (mass%). In the literature, there are also references on the ability to form silicate–phosphate glasses that contain ZnO and are precursors of glass–crystalline materials to which P2O5 was added as a nucleating agent. An example is the work of Demirkesen et al. [27] who obtained fully amorphous silicate glass with the composition 10Li2O–32ZnO–55SiO2–3P2O5 (mass%).

There is little information in the literature on the influence of the addition of ZnO on thermal properties of silicate and phosphate glasses, and even less on silicate–phosphate glasses.

The authors [28] examined the transformation of the vitreous state of the glasses with the composition 50P2O5–(40−xCaO)–10Na2O–xZnO, where x ≤ 20 mol%. Their research shows that adding increased amounts of ZnO caused a linear decrease in the values of the transition temperature (T g) of those glasses. According to the authors, it resulted from the formation of weaker Zn–O–P bonds that replace Ca–O–P bonds and from the decrease in the crosslink density of those glasses. Thermal test carried out on the glasses with the composition (MnO)x·(P2O5)40·(ZnO)60−x where x = 0–20 % mol. [29] showed that a gradual decrease in ZnO content in the structure of the above-mentioned glasses caused a slight decrease in the T g, yet all T g values were close to 415 °C so zinc phosphate matrix is poorly affected by the substitution of ZnO with MnO up to 20 mol%. On the other hand, thermal tests of glasses with the compositions (50−x)ZnO·xMgO·50P2O5 (0 ≥ x ≥ 50) and (60−y)ZnO·yMgO·40P2O5 (0 ≥ x ≥ 60) [30] indicate that a gradual decrease in the content of ZnO and the simultaneous increase in the content of MgO cause an increase in the T g value from ~450 to ~600 °C. Testing glasses from the system Li2O–ZnO–Al2O3–SiO2, Demirkesen and Maytalman [31] observed an increase in the T g value of the glasses parallel to the decrease in the content of ZnO with the simultaneous increase in the amount of the introduced Al2O3. This behaviour can be attributed to strengthening of the bonds within the glass network upon replacement of ZnO by Al2O3. The research done by the authors [32] indicates that the increased addition of ZnO into the structure of bioactive silicate–phosphate glass from the SiO2–CaO–Na2O–P2O5–ZnO system at the expense of the simultaneous decrease in the content of CaO and Na2O does not cause major changes in the T g value or in the crystallization temperature of those glasses.

The object of those studies was silicate–phosphate glasses from the SiO2–P2O5–K2O–CaO–MgO system which can act as slow-dissolving fertilizers providing plant macroelements (P, K, Ca, and Mg) [33], as well as zinc acting as microelement. Zinc plays an active role in many life processes of plants, including the metabolism of carbohydrates, proteins, and phosphorus compounds. It also influences the synthesis of auxins, regulates the formation of ribosomes, and affects the permeability of cell membranes [34].

The presented work includes the results of comparative studies on the influence of the addition of zinc ions introduced at the expense of the decrease in the amount of calcium and magnesium on the glass-forming ability and the thermal characteristics of the glasses from the above-mentioned system, with different content of such network formers as SiO2 and P2O5.

Experimental

Two groups of glasses from SiO2–P2O5–K2O–CaO–MgO system differing in glass network formers content (the Si group of glasses and the P group of glasses) modified by ZnO addition were prepared. In each group of glasses, constant quantities of SiO2, P2O5, and K2O were kept and increasing amount of ZnO was introduced at the cost of decreasing amount of MgO and CaO, with the constant MgO/CaO ratio. The glasses were produced by melting the mixture of raw materials, i.e. SiO2, (NH4)2HPO4, K2CO3, MgO, CaCO3, and ZnO in platinum crucibles at 1100 °C (the phosphate glasses) and at 1450 °C (the silicate glasses). The obtained glasses were ground to 0.1- to 0.3-mm grain size.

The chemical composition of the synthesized glasses was determined by the X-ray fluorescence spectrometry (XRF) method, using the ARL Advant’XP spectrometer.

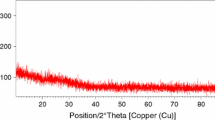

The X-ray diffraction method was used to confirm the amorphous state of the samples using X’Pert Pro Diffractometer (Phillips) with a step of 0.008° and collecting time 45 s.

Thermal stability of the obtained glasses was determined by DSC measurements conducted on STA 449 F3 Jupiter 7 (Netzsch) operating in the heat flux DSC mode. The temperature and heat calibrations of the instrument were performed using the melting temperatures and melting enthalpies of high-purity aluminium, tin, zinc, silver, and gold. The samples (~40 mg) were heated in platinum crucibles at 10 °C min−1 in dry nitrogen atmosphere up to 1100 °C. The glass transformation temperature T g determined as the midpoint of the c p changes in the glass transformation region and changes in specific heat (∆c p) accompanying the glass transformation was determined by applying the Netzsch Proteus Thermal Analysis Program (version 5.0.0.). The ability of glasses to crystallize was evaluated from the values of the thermal stability parameter of glasses (∆T) determined as:

where T onset is the onset temperature of the first crystallization stage and T g is the glass transition temperature of the given sample.

The samples containing the particle size of 0.1–0.3 mm were isothermally heated for 5 h at the crystallization temperatures that were inferred from DSC measurements. The temperature stability was better than ±5 °C. The resulted crystalline phases were detected and identified by XRD method.

Results and discussion

Homogeneous, transparent glasses were obtained from all compositions studied. The nominal chemical composition of the glasses determined by the X-ray fluorescence spectrometry (XRF) method is presented in Table 1.

The chemical analysis of the chosen glasses showed a satisfying conformance of their assumed and real chemical compositions. Therefore, it was assumed that the chemical compositions of all melted glasses fulfil the assumptions.

Glass-forming ability

The XRD tests (Fig. 1) showed that all obtained glasses are fully amorphous in the concentration range in question. Hence, the solubility of ZnO in the structure of the glasses from the SiO2–P2O5–K2O–CaO–MgO system in the examined concentration range does not depend on the content of network formers (SiO2, P2O5).

Glass transition

During heating and cooling, vitreous substances exhibit glass transition effect which is induced by relaxation of stresses being the consequence of a disordered arrangement of the atoms forming the glass structure. The relaxation of stresses in the glass structure taking place at transition temperature (T g) is related to a change in such properties as heat capacity, linear and volume expansion coefficients, and viscosity. Parameters characterizing the glass transition effect depend on the nature and the number of components forming the glassy structure.

The DSC tests showed that the increase in the addition of ZnO into the structure of both glass groups causes a gradual decrease in their T g value (Fig. 2a, b). The T g values are higher by about 150 °C in the silicate matrix glasses (41Si) (Fig. 3) than in the phosphate matrix glasses (41P).

Regardless of the vitreous matrix, the decrease in the T g value was accompanied by a decrease in the ∆c p value, which was better visible in the glasses with the higher content of SiO2 (Table 2).

The changes in the glass transition temperature values (T g) could be explained based on the nature of chemical bonds in the structure of the glasses. The ionicity (i G) value of the bonds of the component atoms with oxygen according to Görlich’s scale [35] was applied as a parameter characterizing the strength of the bonds. It increases with decreasing iconicity. Another parameter is the localization of the bonding electron “L” = \( \overline{{Z_{\text{eff}} }} = \sqrt {Z_{{{\text{eff}}1}} \cdot Z_{{{\text{eff}}2}} } \) [35]. Its value increases with the covalence of the bonds with oxygen, and this parameter has been accepted as a measure of the rigidity of the bonds. The more covalent character of Zn–O bonds (i G = 0.639, L = 1.914) replacing the more ionic bonds such as Ca–O bonds (i G = 0.707, L = 1.725) and Mg–O bonds (i G = 0.670, L = 1.830) made the glass structure more rigid the consequence of which was increased stress in the glass. Its relaxation required less energy and hence lower T g value with the increase in the content of ZnO in the structure of both types of glasses. Simultaneously, due to the more covalent character of P–O bonds (i G = 0.314, L = 2.640) compared to Si–O bonds (i G = 0.428, L = 2.410), the phosphate matrix glasses show lower T g temperature values than silicate matrix glasses. The relaxation of more stresses in the structure of phosphate matrix glasses (41P) than in the structure of silicate matrix glasses (41Si) was accompanied by a slightly higher change in the ∆c p parameter accompanying the transition of the vitreous state.

Crystallization

The thermal tests carried out on the analysed glasses allowed to determine the influence of the increasing addition of ZnO and the network formers on their crystallization ability determined based on the ∆T parameter (Table 2).

It was observed that the crystallization ability of the phosphate matrix glasses (41P) modified by ZnO addition is higher than crystallization ability of the silicate matrix glasses (41Si). The crystallization ability of 41Si glasses decreases with increasing amount of ZnO up to 15 mol% addition, while the addition of 30 mol% of ZnO causes the rapid reduction in ∆T parameter value.

In reference to the already conducted analysis of the atomic reactions in the structures of the examined glasses, based on the characteristic of the nature of the formed chemical bonds, it should be noted that lower T g values accompanied by higher ∆c p values that are related to the reduction in structural stresses (breaking chemical bonds) are equivalent to the higher level of reconstruction of the amorphous structure of the glass which takes place before the crystallization process. Hence, the phosphate matrix glasses have lower thermal stability and higher crystallization ability compared to the silicate matrix glasses. The glass transition effect expressed with such parameters as T g and ∆c p may be treated as an indicator of the level of the reconstruction of the disordered structure of glasses towards their crystallization [36].

The DSC curves of glasses (Fig. 2a, b) show that the crystallization of the base glasses (0Zn) from the two examined groups of glass was a multi-stage process with four stages (Si group glass) and two stages (P group glass). The introduction of the increasing amount of ZnO to the composition of the studied glasses changed the character of exothermal effects whose number was reduced and they were overlapping.

The analysis of the crystallization products of the silicate matrix glasses showed that the main crystallizing phases found in the base glass (0Zn41Si) are orthophosphate of Ca9MgK(PO4)7 type and disilicate of CaMgSi2O6 type (Table 3).

It was found that the increasing amount of zinc ions in the structure of those glasses facilitates the formation of Ca9ZnK(PO4)7 orthophosphate during their crystallization (Fig. 4). It was also observed that the increase in the content of ZnO in the structure of the studied glasses caused a diversification of crystallization products in the form of silicates. Apart from CaMgSi2O6-type silicate (diopside), the crystallization products included Mg2SiO4-type orthosilicate (forsterite) and an orthosilicate containing zinc Zn2SiO4 (willemite).

The XRD study of the base glass with phosphate matrix (0Zn41P) (Table 3) showed that the crystallization products of the glass are polyphosphate compounds composed of KMg(PO3)3 and CaMgP2O7. The type of the formed phosphate networks conforms to the structural classification of phosphate glasses based on the O/P ratio [37]. In the group of the tested phosphate matrix glasses, the O/P ratio was 3.3, which conforms to the structures typical of meta- and pyrophosphates.

The increase in the amount of ZnO up to 15 mol% apart from the above-mentioned types of phosphates results in the formation of pyrophosphates containing zinc, such as K2ZnP2O7 (Fig. 5). For the glass 30Zn41P, there is no evidence of crystallization of KMg(PO3)3 and CaMgP2O7 compounds, but apart from the formation of K2ZnP2O7, the appearance of magnesium-rich metaphosphate of Mg2P4O12 type was detected.

It should also be noted that the introduction of increasing amounts of ZnO into the structure of phosphate matrix glasses inhibits the crystallization of silicate phases.

It was found that the succession of the appearance of the crystallization products in the form of phosphates and silicates in the analysed glasses (Table 4) resulted from the value of Gibbs free enthalpy in the formation of phosphates and silicates from oxides (ΔG) which determines the probability of their formation (Table 4).

Conclusions

Thermal properties of SiO2–P2O5–K2O–CaO–ZnO glasses with various contents of SiO2, and P2O5 were investigated. The increased amount of ZnO-replaced MgO and CaO in the structure of glasses with both silicate and phosphate matrixes caused decrease in T g temperature. The lower T g values observed in the phosphate matrix glasses and the accompanying higher changes in molar heat capacity (Δc p) in contrast to silicate matrix glasses may be regarded as an indicator of the level of transition of their amorphous structure, which facilitates their crystallization. It was found that the increasing amount of zinc in the structure of both groups of glasses facilitates the formation of complex phosphates containing zinc, which took place during their crystallization. On the other hand, the increasing amount of zinc in the structure of the silicate matrix glasses caused the diversification of crystallization products in the form of silicates containing zinc in contrast to the phosphate matrix glass in which the inhibiting effect of zinc on the crystallization of the silicate phases was observed. The nature of the studied thermal transitions is in accordance with the kinds of bonds in the analysed glasses (crystallochemical factors) and Gibbs free enthalpy of the formation of crystalline compounds (chemical affinity of the glass components).

References

Martinez-Martinez R, Speghini A, Bettinelli M, Falcony C, Caldino U. White light generation through the zinc metaphosphate glass activated by Ce3+, Tb3+ and Mn2+ ions. J Lumin. 2009;129:1276–80.

Eriah E, Bhat SG. Optical properties of samarium doped zinc-phosphate glasses. J Phys Chem Solids. 2007;68:581–5.

Fletcher LB, Witcher JJ, Troy N, Reis ST, Brow RK, Krol DM. Effects of rare-earth doping on femtosecond laser waveguide writing in zinc polyphosphate glass. J Appl Phys 2012;112:023109.1-6.

Fletcher LB, Witcher JJ, Troy N, Reis ST, Brow RK, Vazques RM, Osellame R, Krol DM. Femtosecond laser writing of waveguides in zinc phosphate glasses. Opt Mater Express. 2011;1:845–55.

Fletcher LB, Witcher JJ, Troy N, Reis ST, Brow RK, Krol DM. Direct femtosecond laser waveguide writing inside zinc phosphate glass. Opt Mater Express. 2011;19:7929–36.

Canioni L, Bellec M, Royon A, Bousquet B, Cardinal T. Three-dimensional optical data storage using third-harmonic generation in silver zinc phosphate glass. Opt Lett. 2008;33:360–2.

Wilder JA Jr. Glasses and glass ceramics for sealing to aluminum alloys. J Non-Cryst Solids. 1980;388 & 339:879–84.

Morena RM. Phosphate glasses as alternatives to Pb-based sealing frits. J Non-Cryst Solids. 2000;263 & 264:382–7.

Hall SL, Dimai HP, Farley JR. Effects of zinc on human skeletal alkaline phosphatase activity in vitro. Calcif Tissue Int. 1999;64:163–72.

Wu X, Itoh N, Taniguchi T, Nakanishi T, Tatsu Y, Yumoto N, Tanaka K. Zinc-induced sodium-dependent vitamin C transporter 2 expression: potent roles in osteoblast differentiation. Arch Biochem Biophys. 2003;420:114–20.

Ramswamy Y, Wu C, Zhou H, Zreiquat H. Biological response of human bone cells to zinc-modified Ca-Si based ceramics. Acta Biomater. 2008;3:1487–97.

Ito A, Ojima K, Natio H, Ichinose N, Tateischi T. Preparation, solubility and cytompatibility of zinc-releasing calcium phosphate ceramics. J Biomed Mater Res. 2000;50:178–83.

Salih V, Patel A, Knowles JC. Zinc-containing phosphate-based glasses for tissue engineering. Biomed Mater. 2007;2:11–20.

Osinaga PW, Grande RH, Ballester RY, Simionato MR, Delgado Rodrigues CR, Muench A. Zinc sulfate addition to glass-ionomer-based cements: influence on physical and antibacterial properties, zinc and fluoride release. Dent Mater. 2003;19:212–7.

Bright KR, Gerba CP, Rusin PA. Rapid reduction of Staphylococcus aureus populations on stainless steel surfaces by zeolite ceramic coatings containing silver and zinc ions. J Hosp Infect. 2002;52:307–9.

Szumera M, Wacławska I. Effect of molybdenum addition on the thermal properties of silicate–phosphate glasses. J Therm Anal Cal. 2012;109:649–55.

Sułowska J, Wacławska I, Szumera M. Effect of copper addition on glass transition of silicate–phosphate glasses. J Therm Anal Cal. 2012;109:705–10.

Takebe H, Baba Y, Kuwabara M. Dissolution behavior of ZnO–P2O5 glasses in water. J Non-Cryst Solids. 2006;352:3088–94.

Wiench J, Pruski M, Tischendorf B, Otaigbe J, Sales B. Structural studies of zinc polyphosphate glasses by nuclear magnetic resonance. J Non-Cryst Solids. 2000;263–264:101–10.

Tischendorf B, Otaigbe J, Wiench J, Pruski M, Sales B. A study of short and intermediate range order in zinc phosphate glasses. J Non-Cryst Solids. 2001;282:147–58.

Kaur G, Sharma P, Kumar V, Singh K. Assessment of in vitro bioactivity of SiO2–BaO–ZnO–B2O3–Al2O3 glasses: an optico-analytical approach. Mater Sci Eng, C. 2012;32:1941–7.

Hurt J, Philips C. Structural role of zinc oxide in glasses in the system Na2O–ZnO–SiO2. J Am Ceram Sci. 1970;53:269–73.

Minser D, Walden B, White W. Structure of alkali-zinc silicate glasses by Raman Spectroscopy. Commun Am Ceram Sci. 1984:C-47.

Chen X, Brauer D, Karpukhina N, Waite R, Barry M, McKay I, Hill R. ‘Smart’ acid-degradable zinc-releasing silicate glasses. Mater Lett. 2014;126:278–80.

Goel A, Kappor S, Tilocca A, Rajagopal R, Ferreira M. Structural role of zinc in biodegradation of alkali-free bioactive glasses. J Mater Chem B. 2013;1:3073–82.

Aina V, Malavasi G, Fiorio Pla A, Munaron L, Morterra C. Zinc-containing bioactive glasses: surface reactivity and behaviour towards endothelial cells. Acta Biomater. 2009;5:1211–22.

Demirkesen E, Maytalman E. Effect of Al2O3 additions on the crystallization behaviour and bending strength of Li2O–ZnO–SiO2 glasses. J Non-Cryst Solids. 2001;27:287–93.

Abou Neel EA, O’Dell LA, Smith ME, Knowles JC. Processing, characterisation, and biocompatibility of zinc modified metaphosphate based glasses for biomedical applications. J Mater Sci Mater Med. 2008;19:1669–79.

Pascuta P, Bosca M, Borodi G, Culea E. Thermal, structural and magnetic properties of some zinc phosphate glasses doped with manganese ions. J Alloy Compd. 2011;509:4314–9.

Smith CE, Brow RK. The properties and structure of zinc magnesium phosphate glasses. J Non-Cryst Solids. 2014;390:51–8.

Demirkesen E, Maytalman E. Effect of Al2O3 additions on the crystallization behavior and bending strength of a Li2O–ZnO–SiO2 glass-ceramic. Ceram Int. 2001;27:99–104.

Wers E, Oudadesse H. Thermal behavior and excess entropy of bioactive glasses and Zn-doped glasses. J Therm Anal Cal. 2014;115:2137–44.

Stoch L, Stoch Z, Wacławska I. Silicate glass fertilizer. Patent PL 185 229 B1. 2003 [Polish].

Kabata Pendias A, Pendias H. Biogeochemistry of trace elements. Warsaw: Polish Scientific Publishers (PWN); 1993 (in Polish).

Görlich E. The effective charges and the electronegativity. Krakow: Polish Academy of Art and Science; 1997.

Stoch L. Thermal analysis and thermochemistry of vitreous into crystalline state transition. J Therm Anal Cal. 2004;77:7–16.

Brow RK, Click CA, Alam TM. Modifier coordination and phosphate glass networks. J Non-Cryst Solids. 2000;274:9–16.

Barin I, Knacke O. Thermochemical properties of inorganic substances. Berlin: Springer; 1973.

Acknowledgments

The work was supported by Faculty of Materials Science and Ceramics AGH—University of Science and Technology No 11.11.160.617.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sułowska, J., Wacławska, I. & Szumera, M. Comparative study of zinc addition effect on thermal properties of silicate and phosphate glasses. J Therm Anal Calorim 123, 1091–1098 (2016). https://doi.org/10.1007/s10973-015-5044-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-5044-8