Abstract

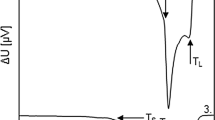

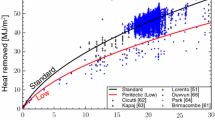

In this study, solidification of a low alloyed steel used for armor material was simulated at various transformation temperatures by the help of thermodynamical calculations using Thermo-Calc software. Differential thermal analysis (DTA) was carried out to determine the critical transformation temperatures for the phases and results were compared with those calculated by Thermo-Calc. It is concluded that the temperatures calculated by Thermo-Calc software are in good agreement with the results obtained from DTA. These results will be very useful to determine the proper austenization temperature having an important effect on the properties of steel serving as an armor material.

Similar content being viewed by others

References

Shi P, Engström A, Höglund L, Chen Q, Sundman B, Ågren J, Hillert M. Computational thermodynamics and kinetics in materials modeling and simulations. J Iron Steel Res Int. 2007;14:210–5.

Laschet G, Benke S. Thermomechanical two-phase modelling of the mushy zone during solidification in casting processes. In: Proceedings, International Conference on Computational Methods for Coupled Problems in Science and Engineering, Barcelona; 2005.

Boettinger WJ, Warren JA, Beckermann C, Karma A. Phase-field simulation of solidification. Annu Rev Mater Res. 2002;32:163–94.

Djebaili H, Zedira H, Djelloul A, Boumaza A. Characterization of precipitates in a 7.9Cr–1.65Mo–1.25Si–1.2 V steel during tempering. Mater Charact. 2009;60:946–52.

Gojic M, Suceska M, Rajic M. Thermal analysis of low alloy Cr–Mo steel. J Therm Anal Calorim. 2004;75:947–56.

Saunders N, Miodownika AP. CALPHAD (calculation of phase diagrams): a comprehensive guide. Oxford: Pergamon Materials Series (Elsevier); 1998.

Andersson JO, Helander T, Höghlund L, Shi P, Sundman B. Thermo-Calc & Dictra, computational tools for materials science. Calphad. 2002;26:273–312.

Erişir E, Prahl U, Bleck W. Effect of precipitation on hot formability of high nitrogen steels. Mater Sci Eng A. 2010;528:519–25.

Karagöz Ş, Atapek ŞH, Yılmaz A. Microstructural and fractographical studies on quenched and tempered armor steels. Mater Test. 2010;52:316–22.

Thermo-Calc TCC Software User’ Guide-Version Q. 2005.

TCFE5, TCS steels/Fe-alloys database (v.5) for Thermo-Calc. 2008.

Shan Y, Luo X, Hu X, Liu S. Mechanisms of solidification structure improvement of ultra pure 17 wt% Cr ferritic stainless steel by Ti, Nb addition. J Mater Sci Technol. 2011;27:352–8.

Huang F, Wang X, Zhang J, Ji C, Fang Y, Yu Y. In situ observation of solidification process of AISI 304 austenitic stainless steel. J Iron Steel Res Int. 2008;15:78–82.

Petrovič DS, Klančnik G, Pirnat M, Medved J. Differential scanning calorimetry study of the solidification sequence of austenitic stainless steel. J Therm Anal Calorim. 2011;105:251–7.

Petrovič DS, Pirnat M, Klančnik G, Mrvar P, Medved J. The effect of cooling rate on the solidification and microstructure evolution in duplex stainless steel. J Therm Anal Calorim. 2012;109:1185–91.

Li D, Liu L, Zhang Y, Ye C, Ren X, Yang Y, Yang Q. Phase diagram calculation of high chromium cast irons and influence of its chemical composition. Mater Design. 2009;30:340–5.

Homolová V, Janovec J, Kroupa A. Experimental and thermodynamic studies of phase transformations in Cr–V low alloy steels. Mater Sci Eng A. 2002;335:290–7.

Hu J, Song H, Yu M, Jiang L. Thermo-Calc calculation and experimental study of microstructure of SUS 410S and SUS 430 ferrite stainless steels at high temperature. In: Proceedings, Sino-Swedish structural materials symposium, China; 2007.

Wang B, Fu W, Li Y, Jiang P, Zhang W, Tian Y. Study of the phase diagram and continuous cooling transformation of 12 % Cr ultra-super-critical rotor steel. Mater Charact. 2008;59:1133–6.

Hu X, Xiao N, Luo X, Li D. Transformation behavior of precipitates in a W-alloyed 10 wt pct Cr steel for ultra-supercritical power plants. J Mater Sci Technol. 2010;26:817–22.

Ma D, Chi H, Zhou J, Yong Q. Microstructure and mechanical properties of martensitic stainless steel 6Cr15MoV. J Iron Steel Res Int. 2012;19:56–61.

Knežević V, Balun J, Sauthoff G, Inden G, Schneider A. Design of martensitic/ferritic heat-resistant steels for application at 650 °C with supporting thermodynamic modelling. Mater Sci Eng A. 2008;477:334–43.

Yan H, Bi H, Li X, Xu Z. Precipitation and mechanical properties of Nb-modified ferritic stainless steel during isothermal aging. Mater Charact. 2009;60:204–9.

Schneider A, Inden G. Simulation of the kinetics of precipitation reactions in ferritic steels. Acta Mater. 2005;53:519–31.

Maweja K, Stumpf W. The design of advanced performance high strength low-carbon martensitic armour steels: microstructural considerations. Mater Sci Eng A. 2008;480:160–6.

Jena PK, Mishra B, Rameshbabu M, Babu A, Singh AK, Sivakumar K, Bhat TB. Effect of heat treatment on mechanical and ballistic properties of a high strength armour steel. Int J Impact Eng. 2010;37:242–9.

Maweja K, Stumpf W, Van der Berg N. The design of advanced performance high strength low-carbon martensitic armour steels : microstructural considerations. Mater Sci Eng A. 2009;519:121–7.

Sangoy L, Meunier Y, Pont G. Steels for ballistic protection. Israel J Tech. 1988;24:319–26.

Crouch IG. Metallic armour: from cast aluminium alloys to high strength steels. Mater Forums. 1998;12:31–7.

Atapek ŞH. Development of a boron added armor steel along the principles of physical metallurgy and evaluation of its ballistic performance. PhD Thesis. Kocaeli University-Turkey, 2010.

Atapek ŞH, Karagöz Ş. Ballistic impact behaviour of a tempered bainitic steel against 7.62 mm armor piercing projectile. Def Sci J. 2011;61:81–7.

Atapek ŞH. Formation of adiabatic shear bands in tempered steel under dynamic loading and their damage effects. Mater Test. 2012;54:625–31.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hakan Atapek, Ş., Erişir, E. & Gümüş, S. Modeling and thermal analysis of solidification in a low alloy steel. J Therm Anal Calorim 114, 179–183 (2013). https://doi.org/10.1007/s10973-012-2930-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2930-1