Abstract

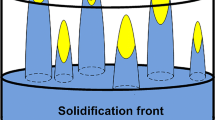

The solidification structure of 430 ferritic stainless steel has been calculated in the solidification process by using 3D-CAFE model under the condition of water cooling. The calculated results consistent with those obtained from experiment. Under watercooling condition, the solidification structure consists of chilled layer, columnar grain zone, transition zone and equiaxed grain zone.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

C. Charbon et al., “3D Stochastic modelling of equiaxed solidification in the presence of grainmovement,” Acta Metallurgical et Materialia, 42(2)(1994), 3953–3966.

M. F. Zhu et al., “A modified cellular automaton model for the simulation of dendritic growth in solidification of alloy,” ISIJ International, 41(5)(2001), 436–445.

G. Gildas et al., “Modeling of macrosegregation and solidification grain structures with a coupled cellular automaton—finite element model,” ISIJ International, 46 (6)(2006), 880–895.

H. Nguyen-Thi et al., “In-situ and real-time investigation of columnar-to-equiaxed transition in metallic alloy,” Metallurgical andMaterials Transactions A, 38(7)(2007), 1458–1464.

C. Hervé et al., “Modeling of equiaxed grain evolution and macrosegregations development in steel ingots,” Transactions of the Indian Institute of Metals, 62(4–5)(2009), 285–290.

T. Wang et al., “Structure simulation in unidirectionally solidified turbine blade by dendrite envelope tracking model (II): model validation and defects prediction,” Transactions of Nonferrous Metals Society of China, 16(4)(2006), 753–759.

M. A. Martorano et al., “A solutal interaction mechanism for the columnar-to-equiaxed transition in alloy solidification,” Metallurgical and Materials Transactions A, 34(8)(2003), 1657–1674.

G. Guillemota et al., “Interaction between single grain solidification and macrosegregation: Application of a cellular automaton—finite element model,” Journal of Crystal Growth, 303(1)(2007), 58–68.

J. S. Hyunget et al., “The effect of texture on riding of ferritic stainless steel,” Acta Materialia, 51(16)(2003), 4693–4706.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Pang, R., Li, C., Wang, F., Hu, L. (2015). Simulation Computation of 430 Ferritic Stainless Steel Solidification. In: Jiang, T., et al. 6th International Symposium on High-Temperature Metallurgical Processing. Springer, Cham. https://doi.org/10.1007/978-3-319-48217-0_56

Download citation

DOI: https://doi.org/10.1007/978-3-319-48217-0_56

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48603-1

Online ISBN: 978-3-319-48217-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)