Abstract

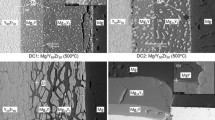

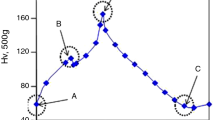

The effects of ageing treatment on phase transformations in Mg–Al alloy have been assessed. The techniques of scanning and transmission electron microscopy, microhardness and differential scanning calorimetric tests were used to characterize the materials obtained after application of artificial ageing. An ageing treatment at 175 °C causes the β-Mg17Al12 precipitation to become evenly distributed along the grain boundary and within the grain together with precipitation of the Al6Mn and the Τ-Mg32(Al,Zn)49 phases. The transformation processes are associated with increased hardness values. The hardness value increases with the ageing time and attains maximum value after 10 h of ageing time. The presence of the β-Mg17Al12 phase acts as an effective barrier to dislocation motion, thus improving the mechanical properties of the alloy. Analysing the DSC data it is found a shift of peak temperatures to higher temperatures with increasing heating rates, which suggests that the solid state reactions are thermally activated and kinetically controlled. The fraction and the rate of transformation, the transformation function and the kinetic parameters such as activation energy and frequency factor for the alloy in artificial ageing conditions were determined.

Similar content being viewed by others

References

Ishikawa K, Watanabe H, Mukai T. High strain rate deformation behaviour of an AZ91 magnesium alloy at elevated temperatures. Mater Lett. 2005;59:1511–5.

Ma YQ, Chen RS, Han EH. Keys to improving the strength and ductility of the AZ64 magnesium alloy. Mater Lett. 2007;61:2527–30.

Ohno M, Mirkovic D, Schmid-Fetzer R. Liquidus and solidus temperatures of Mg-rich Mg–Al–Mn–Zn alloys. Acta Mater. 2006;54:3883–91.

Guan YC, Zhou W. Calorimetric analysis of AZ91D magnesium alloy. Mater Lett. 2008;62:4494–6.

Song G, Atrens A, Dargusch M, Zhang B. Corrosion behaviour of AZ21, AZ501 and AZ91 in sodium chloride. Corr Sci. 1998;40:1769–91.

Bassani P, Gariboldi E, Tuissi A. Calorimetric analysis of AM60 magnesium alloy. J Therm Anal Calorim. 2005;80:739–47.

Celotto S, Bastow TJ. Study of precipitation in aged binary Mg–Al and ternary Mg–Al–Zn alloys using Al-27 NMR spectroscopy. Acta Mater. 2001;49:41–51.

Boumerzoug Z, Fatmi M. Effect of heat treatments on discontinuous precipitation kinetics in Al-30 wt% Zn alloy. Mater Charact. 2009;60:768–74.

Barbagallo S, Laukli HI, Lohne O, Cerri E. Divorced eutectic in a HPDC magnesium–aluminum alloy. J Alloy Compd. 2004;378:226–32.

Sevik H, Açikgöz S, Kurnaz SC. The effect of tin addition on the microstructure and mechanical properties of squeeze cast AM60 alloy. J Alloy Compd. 2010;508:110–4.

Daoudi MI, Triki A, Redjaimia A. DSC study of the kinetic parameters of the metastable phases formation during non-isothermal annealing of an Al–Si–Mg alloy. J Therm Anal Calorim. 2011;104:627–33.

Petrovič DS, Pirnat M, Klančnik G, Mrvar P, Medved J. The effect of cooling rate on the solidification and microstructure evolution in duplex stainless steel. A DSC study. J Therm Anal Calorim. 2012;109:1185–91.

Smetana B, Zlá S, Kroupa A, Žaludová M, Drápala J, Burkovič R, Petlák D. Phase transition temperatures of Sn–Zn–Al system and their comparison with calculated phase diagrams. J Therm Anal Calorim. 2012;110:369–78.

Ohno M, Mirkovic D, Schmid-Fetzer R. Phase equilibria and solidification of Mg-rich Mg–Al–Zn alloys. Mater Sci Eng A. 2006;421:328–37.

Nicolas M, Deschamps A. Precipitate microstructures and resulting properties of Al–Zn–Mg metal inert gas-weld heat-affected zones. Metall Mater Trans A. 2004;35:1437–48.

Abis S, Massazza M, Menegucci P, Riontino G. Early ageing mechanisms in a high-copper AlCuMg alloy. Scripta Mater. 2001;45:685–91.

Vassilev V, Aljihmani L, Paranova V. Phase equilibria in the GeSe2–SnTe system. J Therm Anal Calorim. 2004;76:727–35.

Ghosh KS, Gao N. Determination of kinetic parameters from calorimetric study of solid state reactions in 7150 Al–Zn–Mg alloy. Trans Nonferrous Met Soc China. 2011;21:1199–209.

Wang WX, Chen JJ, Jiang BL, Yuan S, Jie WQ. Deformed microstructure and the eutectic melting activity energy of AZ91D magnesium alloy by SIMA method. Sp Cast Nonferrous Alloys. 2005;25:205–7.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Malakhov DV, Abou Khatwa MK. Constructing a self-consistent integral baseline by using cubic splines. J Therm Anal Calorim. 2007;87:595–9.

Smith GW, Baxter WJ, Mishra RK. Precipitation in 339 and 2124 aluminum: a caveat for calorimetry. J Mater Sci. 2000;35:3871–80.

Banerjee S, Robi PS, Srinivasan A. Calorimetric study of precipitation kinetics of Al–Cu–Mg and Al–Cu–Mg–0.06 wt% Sn alloys. Met Mater Int. 2010;16:523–31.

Gómez de Salazar JM, Barrena MI. Role of Al2O3 particulate reinforcements on precipitation in 7005 Al–matrix composites. Scripta Mater. 2001;44:2489–95.

Acknowledgements

The authors would like to thank MAT2010-20311 and Santander–UCM GR35/10-A projects for the financial support they provided.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barrena, M.I., Gómez de Salazar, J.M., Pascual, L. et al. Determination of the kinetic parameters in magnesium alloy using TEM and DSC techniques. J Therm Anal Calorim 113, 713–720 (2013). https://doi.org/10.1007/s10973-012-2791-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2791-7