Abstract

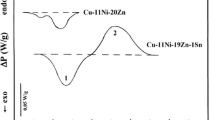

The precipitation processes in a Cu–1.0 at.%Co–0.5 at.%Ti (Cu–1.5 at.%Co2Ti) alloy were studied using differential scanning calorimetry (DSC), transmission electron microscopy (TEM), and microhardeness measurements. The analysis of the calorimetric curves from room temperature to 900 K shows the presence of two exothermic reactions attributed to the formation of CoTi and Co2Ti particles in the copper matrix. On the basis of enthalpy calculations, it was found that the decomposition begins with the precipitation of CoTi, followed by the formation of Co2Ti particles. The activation energies calculated using the modified Kissinger method were lower than the ones corresponding to diffusion of cobalt and titanium in copper. Kinetic parameters were obtained by a convolution method based on the Johnson–Mehl–Avrami (JMA) formalism. The values obtained for the parameter n were indicative of a particle nucleation process from preexistent nuclei. Microhardness measurements and TEM micrographs confirmed the formation of the mentioned phases.

Similar content being viewed by others

References

Varschavsky A, Donoso E. Energetic and kinetic evaluations conducted in a quasi-binary Cu-1at.%Co2Si alloy through DSC. J Thermal Anal Cal. 2002;68:231–41.

Donoso E. Calorimetric evaluation of precipitation in Cu rich, Cu-Co-Si. Rev Metal Madrid. 2001;37:492–8.

Varchavsky A, Donoso E. DSC study of precipitation processes in Cu-Co-Si alloys. J Thermal Anal Cal. 2003;74:41–56.

Albert B. Löslichkeit und ausscheidungsvorgänge in Cu-Co-Si-Legierungen. Z Metallkde. 1985;76:475–8.

Mineau L, Hamar-Thibault S, Allibert CH. Precipitation in Cu-rich Co-Ti ternary alloys. Phys Stat Sol A. 1992;134:93–105.

Batra IS, Laik A, Kale GB, Dey GK, Kulkarni UD. Microstructure and properties of a Cu-Ti-Co alloy. Mater Sci Eng A. 2005;402:118–25.

Donoso E, Diaz G, Criado JM. Kinetics analysis of precipitation in a quasi-binary Cu-1at.% CoTi alloy. J Thermal Anal Cal. 2008;91:491–5.

Fortina G, Leoni M. Caratteristiche strutturali, meccaniche e di resistenza alla corrosion di nuovi tipi di bronzo di alluminio al cobalto. Metal Italiana. 1972;10:470–80.

Sierpinski Z, Gryziecki J. Phase transformations and strengthening during ageing of CuNi10Al3 alloy. Mater Sci Eng A. 1999;264:279–85.

Sierpinski Z, Gryziecki J. Precipitation and recrystallization processes during ageing of plastically deformed Cu-6wt%Ni-3wt%Al. Z Metallkd. 1998;89:551–3.

Donoso E, Diánez MJ, Sayagués MJ, Criado JM, Varschavsky A, Díaz G. Non isothermal calorimetric study of the precipitation processes in a Cu-10%Ni-3%Al alloy. Rev Metal Madrid. 2007;43:117–24.

Pfeifer HU, Bhan S, Schubert K. Zum aufbau des systems Ti—Ni—Cu und einiger quasihomologer legierungen. J Less-common Met. 1968;14:291–302.

Murray JL. The Al-Mg (Aluminium-Magnesium) system. Bull Alloy Phase Diagr. 1982;3:74–85.

Gupta KP. The Co-Cu-Ti (cobalt-copper-titanium) system. J Phase Equil. 2003;24:272–5.

Gotor FJ, Criado JM, Málek J, Koga N. Kinetic analysis of solid-state reactions: the universality of master plots for analyzing isothermal and nonisothermal experiments. J Phys Chem A. 2000;104:10777–82.

Mittemeijer EJ, Cheng L, Van der Shaaf PJ, Brakman CM, Korevaar BM. Analysis of nonisothermal transformation kinetics; tempering of iron-carbon and iron-nitrogen martensites. Metall Trans A. 1988;19:925–32.

Brown AM, Ashby MF. Correlations for diffusion constants. Acta Metall. 1980;28:1085–101.

Coats AW, Redfern JP. Kinetic parameters from thermogravimetric data. Nature 1964;201:68–9.

Ozawa T. A modified method for kinetic analysis of thermoanalytical data. J Thermal Anal. 1976;9:369–73.

Borrego A, González-Doncel G. Calorimetric study of 6061-Al-15vol.%SiCw PM composites extruded at different temperatures. Mater Sci Eng A. 1998;245:10–8.

Borrego A, González-Doncel G. Reply to comments on: calorimetric study of 6061-Al-15vol.%SiCw PM composites extruded at different temperatures. Mater Sci Eng A. 2000;276:292–5.

Christian JW. The theory of transformation of metals and alloys. 2nd ed ed. England: Pergamon Press; 1971. p. 534.

Acknowledgements

The authors would like to acknowledge the Fondo Nacional de Desarrollo Científico y Tecnológico (FONDECYT) for the financial support, Project No. 1090010. The access to specialized facilities and laboratories provided by the Instituto de Ciencias de Materiales de Sevilla, Spain and the Departamento de Ciencia de los Materiales, Facultad de Ciencias Físicas y Matemáticas, Universidad de Chile is also greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Donoso, E., Zúñiga, A., Diánez, M.J. et al. Nonisothermal calorimetric study of the precipitation processes in a Cu–1Co–0.5Ti alloy. J Therm Anal Calorim 100, 975–980 (2010). https://doi.org/10.1007/s10973-009-0642-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0642-y