Abstract

The curing kinetics of lignin-novolac and methylolated lignin-novolac resins were studied using non-isothermal methods employing differential scanning calorimetry (DSC) at different heating rates. The Belichmeier, Ozawa and Kissinger methods were applied, which give the kinetic parameters of the curing process studied. In addition, the model-fitting Coats-Redfern method was used to analyze the experimental data. The kinetic study evaluated the effect of the lignin (softwood ammonium lignosulfonate), methylolated or not, on the resin curing process. Results for lignin-novolac and modified lignin-novolac resins were compared with a commercial novolac resin as a reference. When lignosulfonate is modified by methylolation and is incorporated in the novolac resin, there is an important reduction in activation energy. The lignin-novolac showed slightly higher values of activation energy than methylolated-lignin resins, but lower values than commercial resins. This behavior has been attributed to the extra methyol groups introduced by lignosulfonate.

Similar content being viewed by others

References

Forss KG, Fuhrmann A. Finnish plywood, particleboard, and fireboard made with a lignin-base adhesive. Forest Prod J. 1979;29(7):39–43.

Vázquez G, González-Álvarez J, López-Suevos F, Freire S, Antorrena G. Curing kinetics of tannin–phenol–formaldehyde adhesives as determined by DSC. J Therm Anal Calorim. 2002;70(1):19–28.

Calvé LR, Shields JA, Blanchette L, Fréchet JMJ. A practical lignin-based adhesive for waferboard/OSB. Forest Prod J. 1988;38(5):15–20.

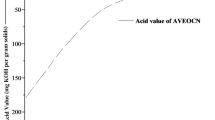

Alonso MV, Rodríguez JJ, Oliet M, Rodríguez F, García J, Gilarranz MA. Characterization and structural modification of ammonic lignosulfonate by methylolation. J Appl Polym Sci. 2001;82(11):2661–8.

Allan GG, Dalan JA, Foster NC. Modification of lignins for use in phenolic resins. In: Adhesives from renewable resources. American Chemical Society, Symposium Series; 1989.

Gardziella A, Pilato LA, Knop A. Phenolic resins: chemistry, applications, standardization, safety and ecology. New York: Springer-Verlag; 2000.

Lu MG, Shim MJ, Kim SW. Curing behavior of an unsaturated polyester system analyzed by Avrami equation. Thermochim Acta. 1998;323(1–2):37–42.

Park B-D, Riedl B, Hsu EW, Shields J. Differential scanning calorimetry of phenol-formaldehyde resins cure-accelerated by carbonates. Polymer. 1999;40(7):1689−99.

Alonso MV, Oliet M, Pérez JM, Rodríguez F, Echeverría J. Determination of curing kinetic parameters of lignin–phenol–formaldehyde resol resins by several dynamic differential scanning calorimetry methods. Thermochim Acta. 2004;419(1–2):161–7.

Belichmeier JA, Cammenga HK, Schneider PB, Steer AG. A simple method for determining activation energies of organic reactions from DSC curves. Termochim Acta. 1998;310(1–2):147–51.

Ozawa T. A new method of analysing thermogravimetric data. Bull Chem Soc Jpn. 1965;38(1):1881–6.

Kissinger HE. Reaction kinetics in diferential thermal analysis. Anal Chem. 1957;29:1702–6.

Coats AW, Redfern JP. Kinetic parameters from thermogravimetric data. Nature. 1964;201(4914):68–9.

Maciejewski M. Computational aspects of kinetic analysis. Part B: The ICTAC Kinetics Project – the decomposition kinetics of calcium carbonate revisited, or some tips on survival in the kinetic minefield. Thermochim Acta. 2000;355(1–2):145–54.

Carotenuto G, Nicolais L. Kinetic study of phenolic resin cure by IR spectroscopy. J Appl Polym Sci. 1999;74(11):2703–15.

He G, Riedl B, Aït-Kadi A. Curing process of powdered phenol–formaldehyde resol resins and the role of water in the curing systems. J Appl Polym Sci. 2003;89(5):1371–8.

Wang M, Wei L, Zhao T. Cure study of addition-cure-type and condensation-addition-type phenolic resins. Eur Polym J. 2005;41(5):903–12.

Alonso M, Oliet M, García J, Rodríguez F, Echeverría J. Gelation and isoconversional kinetic analysis of lignin-phenol-formaldehyde resol resins cure. Chem Eng J. 2006;122(3):159–66.

Alonso M, Oliet M, García J, Rodríguez F, Echeverría J. Transformation of dynamic DSC results into isothermal data for the curing kinetics study of the resol resins. J Therm Anal Calorim. 2006;86(3):797–802.

Vázquez G, López-Suevos F, González-Alvarez J, Antorrena G. Curing process of phenol–urea–formaldehyde–tannin (PUFT) adhesives. J Therm Anal Calorim. 2005;82(1):143–9.

Gabilondo N, López M, Ramos J, Echeverría J, Mondragon I. Curing kinetics of amine and sodium hydroxide catalyzed phenol–formaldehyde resins. J Therm Anal Calorim. 2007;90(1):229–36.

Siimer K, Kaljuvee T, Christjanson P, Pehk T, Saks I. Effect of alkylresorcinols on curing behaviour of phenol–formaldehyde resol resin. J Therm Anal Calorim. 2008;91(2):365–73.

Tejado A, Kortaberria G, Labidi J, Echeverria JM, Mondragon I. Isoconversional kinetic analysis of novolac-type lignophenolic resins cure. Thermochim Acta. 2008;471(1–2):80–5.

Pérez JM, Rodríguez F, Alonso MV, Oliet M, Echeverría JM. Characterization of a novolac resin substituting phenol by ammonium lignosulfonate as filler or extender. Bioresources. 2007;2(2):270–83.

Ysbrandy RE, Sanderson RD, Gerischer GFR. Adhesives from autohydrolysis bagasse lignin. Part I. Holzforschung. Holzforschung. 1992;46(3):249–52.

Martin JL, Salla JM. Models of reaction commonly employed in the curing of thermosetting resins. Thermochim Acta. 1992;207:279–304.

Bindu RL, Reghunadhan CP, Ninan KN. Phenolic resins bearing maleimide groups: synthesis and characterization. J Polym Sci Pol Chem. 2000;38(3):641–52.

Krajnc M, Golob J, Podraj J, Barboric F. A kinetic model of resol curing in the production of industrial laminates. Acta Chim Slov. 2000;47:99–109.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404(1–2):163–76.

Catalani A, Bonicelli MG. Kinetics of the curing reaction of a diglycidyl ether of bisphenol A with a modified polyamine. Thermochim Acta. 2005;438(1–2):126–9.

Doyle CD. Series approximations to the equation of thermogravimetric data. Nature.1965;207(4994):290–1.

Murray P, White J. Kinetic of the thermal dehydration of clays. Part IV. Interpretation of the differential thermal analysis of the clay minerals. Trans Brot Ceram Soc. 1955;54:204–38.

Weiling P. Development de noeveaux adhesifs bases sur des derives de la lignine. UMI Dissertation Service; 1994.

Tejado A, Kortaberria G, Peña J, Labidi J, Echeverria JM, Mondragon I. Isocyanate curing of novolac-type ligno–phenol–formaldehyde resins. Ind Crops Prod. 2008;27(2):208–13.

Matuana LM, Riedl B, Barry AO. Caracterisation cinetique par analyse enthalpique differentielle des resines phenol–formaldehyde a base de lignosulfonates. Eur Polym J. 1993;29(4):483–90.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;340–341:53–68.

Agrawal R, Saxena NS, Sharma KB, Thomas S, Sreekala MS. Activation energy and crystallization kinetics of untreated and treated oil palm fibre reinforced phenol formaldehyde composites. Mater Sci Eng. 2000;A277(1–2):77–82.

de Medeiros ES, Agnelli JAM, Joseph K, de Carvalho LH, Mattoso LHC. Curing behavior of a novolac-type phenolic resin analyzed by differential scanning calorimetry. J Appl Polym Sci. 2003;90(6):1678–82.

Acknowledgements

The authors gratefully acknowledge the support of “Ministerio de Ciencia y Tecnología” (projects CTQ2004-02031/PPQ and CTQ2007-64071).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pérez, J.M., Rodríguez, F., Alonso, M.V. et al. Curing kinetics of lignin-novolac phenolic resins using non-isothermal methods. J Therm Anal Calorim 97, 979–985 (2009). https://doi.org/10.1007/s10973-009-0103-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0103-7