Abstract

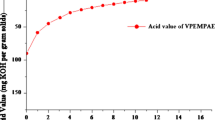

In the present research article, a detailed study on the synthesis, characterization, and structure–property correlation study of the vinyl ester resin (AVEOCN) based on the rosin modified o-cresol-formaldehyde epoxy novolac resin has been done. The rosin was condensed with o-cresol formaldehyde novolac resin to obtain the product (AOCN). The AOCN resin was epoxidized and subsequently esterified with methacrylic acid using triphenylphosphine as a catalyst and inhibitor hydroquinone to get vinyl ester resin (AVEOCN) having acid value ~ 7 mg of KOH per gram of solid. The chemical structures were confirmed using FT-IR, 1H-NMR, 13C-NMR, and DEPT-135° spectroscopic techniques, and their number average molecular weights were evaluated using 1H-NMR spectroscopy as well as Gel Permeation Chromatographic technique (GPC). The curing dynamics of synthesized VER with lignin modeled compounds, methacrylated eugenol (ME) and methacrylated guaiacol (MG), and petroleum-based styrene as reactive diluents was studied using Differential Scanning Calorimetry (DSC). The thermal stability analysis and mechanical performance of the VER samples were done using Thermogravimetric analysis (TGA) and Universal Testing Machine (UTM), respectively. Chemical resistance tests of the above VER samples were also assessed via exposing the sample coated panels to the different chemical environments for 90 days and their % weight loss was determined. The surface morphology of exposed samples was also studied using Scanning Electron Microscopy (SEM). The results obtained were compared to VER systems based on petroleum products and epoxy resins systems and the superior performance of rosin-modified VER systems indicate that they are suited for pressing demands for coating applications.

Similar content being viewed by others

Availability of data and material

Data will be available on request.

References

Jaswal S, Gaur B (2014) New trends in vinyl ester resins. Rev Chem Eng 30:567–581. https://doi.org/10.1515/revce-2014-0012

Gaur B, Rai JSP (1992) Curing and decomposition behaviour of vinyl ester resins. Polymer (Guildf) 33:4210–4214. https://doi.org/10.1016/0032-3861(92)90631-6

Jin L, Agag T, Ishida H (2013) Use of allyl-functional benzoxazine monomers as replacement for styrene in vinyl ester resins. Polym Int 62:71–78. https://doi.org/10.1002/pi.4279

Ragauskas AJ, Williams CK, Davison BH et al (2006) The path forward for biofuels and biomaterials. Science 311:484–489. https://doi.org/10.1126/science.1114736

Bu Z, Hu J, Li B (2014) Thermochimica Acta Novel silicon-modified phenolic novolac resins : Non-isothermal curing kinetics, and mechanical and thermal properties of their biofiber-reinforced composites. Thermochim Acta 575:244–253. https://doi.org/10.1016/j.tca.2013.11.003

Pan G, Du Z, Zhang C et al (2007) Synthesis, characterization, and properties of novel novolac epoxy resin containing naphthalene moiety. Polymer 48:3686–3693. https://doi.org/10.1016/j.polymer.2007.04.032

Hirano K, Asami M (2013) Phenolic resins-100 years of progress and their future. React Funct Polym 73:256–269. https://doi.org/10.1016/j.reactfunctpolym.2012.07.003

Chen GF (1992) Developments in the field of rosin chemistry and its implications in coatings. Prog Org Coatings 20:139–167. https://doi.org/10.1016/0033-0655(92)80002-E

Scala JJ, Logan MS, Sands JM, Palmese GR (2008) Composites based on bimodal vinyl ester resins with low hazardous air pollutant contents. Compos Sci Technol 68:1869–1876. https://doi.org/10.1016/j.compscitech.2008.01.003

Zhang J (2012) Rosin-based chemicals and polymers. Smithers Rapra Technology Ltd, United Kingdom

Thakur T, Jaswal S, Parihar S, Singha AS (2020) Bio-based Epoxy Thermosets with Rosin Derived Imidoamine Curing Agents and their Structure-Property Relationships. Express Polym Lett 14:512–529. https://doi.org/10.3144/expresspolymlett.2020.42

Jaswal S, Gaur B (2015) Structure-property correlation study of bio-based multifunctional vinyl ester resin in presence of methacrylated lignin model compounds. Polym Sci - Ser B 57:417–433. https://doi.org/10.1134/S1560090415050048

Wang Z, Gao P, Chen P (2000) Synthetic reaction of rosin-modified phenolic resin for offset inks. Pigment Resin Technol 29:88–92. https://doi.org/10.1108/03699420010317834

Tuck N, Coyard H, Deligny P (2000) Resins for surface coatings. Wiley, New York

Panda H (2005) Handbook on Speciality Gums, Adhesives, Oils, Rosin & Derivatives, Resins, Oleoresins, Katha. Asia Pacific Business Press Inc, New Delhi, Chemicals with Other Natural Products

Okoshi N, Kudo K, Shimoyama S (1981) Process for producing oil-modified and rosin-modified phenolic resin for printing inks. US patent 4(391):640A

Deblasi DS, Walsh JP (1989) Phenolic-modified rosin ester printing inks. US patent 4(857):624

Kang DW, Yoon DK, Ji SH (2000) Synthesis and characterization of rosinester modified with p-nonylphenolic resole. J Ind Eng Chem 6:256–261

Sathe, Sharad S (1986) Process for the preparation of N-acetyl-P-aminophenol. US Patent 4,565,890

Thakur T, Jaswal S, Gaur B, Singha AS (2020) Thermo-mechanical properties of rosin-modified o-cresol novolac epoxy thermosets comprising rosin-based imidoamine curing agents. Polym Eng Sci 1–21. https://doi.org/10.1002/pen.25562

Pal N, Srivastava A, Rai JSP (2003) Synthesis of vinyl ester resins in the presence of monoepoxies: A kinetic study. Polym - Plast Technol Eng 42:105–122. https://doi.org/10.1081/PPT-120016338

(1954) Division of Paint, Plastics and Printing Ink Chemistry. Chem Eng News Arch 32:3845–3846. https://doi.org/10.1021/cen-v032n039.p3845

Jaswal S, Gaur B (2013) Curing and decomposition behaviour of cresol novolac based vinyl ester resin. Chem Eng Trans 32:1591–1596. https://doi.org/10.3303/CET1332266

Mohan P (2013) A Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym - Plast Technol Eng 52:107–125. https://doi.org/10.1080/03602559.2012.727057

Agrawal S, Singhal R, Rai JSP (1999) Curing and rheological behavior of vinyl ester resins prepared in the presence of tertiary amines. J Macromol Sci Pure Appl Chem 36A:741–757. https://doi.org/10.1081/ma-100101561

Jaswal S, Gaur B (2015) Green methacrylated lignin model compounds as reactive monomers with low VOC emission for thermosetting resins. Green Process Synth 4:191–202. https://doi.org/10.1515/gps-2015-0005

Atta AM, El-Saeed SM, Farag RK (2006) New vinyl ester resins based on rosin for coating applications. React Funct Polym 66:1596–1608. https://doi.org/10.1016/j.reactfunctpolym.2006.06.002

Jaillet F, Nouailhas H, Boutevin B, Caillol S (2015) Synthesis of novel vinylester from dicyclopentadiene prepolymer. Eur Polym J 71:248–258. https://doi.org/10.1016/j.eurpolymj.2015.08.002

Jaswal S, Thakur T, Gaur B, Singha AS (2021) High-performance gum rosin-modified hyperbranched vinyl ester resin derived from multifunctional pentaerythritol. Polym Bull. https://doi.org/10.1007/s00289-020-03511-x

McCool DJ (2000) Van Nostrand’s scientific encyclopedia, revised 8th edition. J Chem Educ 77:36. https://doi.org/10.1021/ed077p36.1

Jaswal S, Gaur B (2015) Morphological, Mechanical and Physio-chemical Performance of ortho-Cresol Epoxy Novolac Based Vinyl Ester Resin. Polish J Chem Technol 17:1–7. https://doi.org/10.1515/pjct-2015-0041

Sultania M, Rai JSP, Srivastava D (2010) Studies on the synthesis and curing of epoxidized novolac vinyl ester resin from renewable resource material. Eur Polym J 46:2019–2032. https://doi.org/10.1016/j.eurpolymj.2010.07.014

Smith CA (1987) Characterisation of polymers used in printed circuit board manufacture. Polym Test 7:79–84. https://doi.org/10.1016/0142-9418(87)90002-X

Dharwadkar SR, Kharkhanawala MD (1969) In Thermal Analysis in Organic Materials and Physical Chemistry. Academic Press, New York, Vol, p 2

Garg MS, Srivastava D (2014) Effect of glycidyl methacrylate (GMA) content on thermal and mechanical properties of ternary blend systems based on cardanol-based vinyl ester resin, styrene and glycidyl methacrylate. Prog Org Coatings 77:1208–1220. https://doi.org/10.1016/j.porgcoat.2014.03.029

Siva P, Varma IK, Patel DM, Sinha TJM (1994) Effect of structure on properties of vinyl ester resins. Bull Mater Sci 17:1095–1101. https://doi.org/10.1007/BF02757587

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest/Competing interests

No conflicts to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jaswal, S., Thakur, T. & Gaur, B. Rosin-modified o-cresol novolac based vinyl ester thermosets containing methacrylated lignin model compounds: synthesis, curing and thermo-mechanical analysis. J Polym Res 28, 111 (2021). https://doi.org/10.1007/s10965-021-02475-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02475-4