Abstract

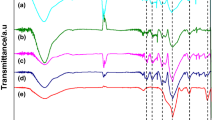

Organic–inorganic hybrid coatings of crosslinked epoxy and thiol silicates (TGST) were synthesized for the corrosion protection of low carbon steel via a waterborne sol-gel route. The coatings were synthesized in two stages; in the first step two separate aqueous formulations of epoxy and thiol decorated silica colloids were prepared and subsequently crosslinked in a 1:1 ratio in the second stage. The structure and rate of crosslinking was monitored using Raman spectroscopy. Formulation stability was measured based on viscosity changes and pot-life assessment. The novel material was characterized for its particle size using dynamic light scattering. Viscosity average molecular weight was calculated using Fikentscher’s equation and using polyethylene oxide molecular weights as a calibration standard. The covalently bonded epoxy-thiol silicate thin-film coating was uniform and defect free. Accelerated corrosion resistance was tested by exposing the panels to standard salt solution tests. TGST showed a 96% improvement in corrosion inhibition over the non-crosslinked formulations in a corrosive environment. The synthesis and characterization of TGST using a simple approach, revealed key synthetic parameters for generating optimized sol-gel corrosion prevention materials.

Schematic representation of the crosslinking of the epoxy (TG) and thiol (ST) decorated silica colloids by the waterborne sol-gel route at room temperature to form the crosslinked TGST formulation effective for the corrosion prevention of low carbon steel substrates

Highlights

-

Crosslinked epoxy-thiol decorated silicate coatings for corrosion prevention were synthesized.

-

Green, non-toxic formulations were prepared via a waterborne sol-gel route at room temperature.

-

Enhanced barrier properties showing 96% improved corrosion resistance of crosslinked coatings over the non-crosslinked formulations on low carbon steel were achieved.

-

Coatings were smooth, defect-free, and showed easy applicability to suit dip or spray coating.

-

The two-component coating system showed a commercially attractive pot-life.

Similar content being viewed by others

References

Koch G, Varney J, Thompson N, Moghissi O, Gould M, Payer J (2016) International Measures of Prevention, Application, and Economics of Corrosion Technologies Study. NACE International IMPACT Report

Brinker CJ, Scherer GW (2013) Sol-gel science: the physics and chemistry of sol-gel processing. Academic press, San Diego, California, USA

Vreugdenhil AJ, Woods ME (2005) Triggered release of molecular additives from epoxy-amine sol–gel coatings. Prog Org Coat 53(2):119–125

Woods ME, Vreugdenhil AJ (2006) Continuously responsive epoxy-amine cross-linked silicon sol–gel materials. J Mater Sci 41(22):7545–7554

Feng Y, Cheng YF (2016) Fabrication of Halloysite nanocontainers and their compatibility with epoxy coating for anti-corrosion performance. Corros Eng Sci Technol 51(7):489–497

Rezaee S, Rashed G, Golozar MA (2013) Effect of water/alkoxide molar ratio on the synthesis process and electrochemical behavior of yttria-doped zirconia sol-gel films. Iran J Oil Gas Sci Technol 2(1):57–70

Al-Sagheer F, Merchant S (2011) Visco-elastic properties of chitosan–titania nano-composites. Carbohydr Polym 85(2):356–362

Guin AK, Nayak S, Rout TK, Bandyopadhyay N, Sengupta DK (2011) Corrosion resistance nano-hybrid sol–gel coating on steel sheet. ISIJ Int 51(3):435–440

Guin A, Nayak S, Rout T, Bandyopadhyay N, Sengupta D (2012) Corrosion behavior of nanohybrid titania–silica composite coating on phosphated steel sheet. J Coat Technol Res 9(1):97–106

Brinker CJ, Scherer G (1990) The Processing and the Chemistry of Sol-Gel Processing. In: Sol-gel sciences. Academic Press, San Diego, California, USA

Li G, Wang X, Li A, Wang W, Zheng L (2007) Fabrication and adhesive properties of thin organosilane films coated on low carbon steel substrates. Surf Coat Technol 201(24):9571–9578

Bera S, Udayabhanu G, Narayan R, Rout T (2016) High performance chrome free coating for white rust protection of zinc. Mater Sci Technol 32(4):338–347

Deflorian F, Rossi S, Fedrizzi L, Fedel M (2008) Integrated electrochemical approach for the investigation of silane pre-treatments for painting copper. Prog Org Coat 63(3):338–344

Balaji J, Sethuraman MG (2016) Corrosion protection of copper with hybrid sol-gel containing 1H-1, 2, 4-triazole-3-thiol. Iran J Chem Chem Eng 35(4):61–71

Vreugenhil AJST (2016) Anti-corrosion sol-gel material. Patent CA2979568A1. Trent University, Peterborough Ontario, Canada

Fikentscher VH (1932) Systematik der cellulosen auf grund ihrer viskosität in lösung. Zellul Chem 13:58

Beccaria AM, Padeletti G, Montesperelli G, Chiaruttini L (1999) The effect of pretreatments with siloxanes on the corrosion resistance of aluminium in NaCl solution. Surf Coat Technol 111(2):240–246

Rueden CT, Schindelin J, Hiner MC, DeZonia BE, Walter AE, Arena ET, Eliceiri KW (2017) ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinformatics 18(1):529. https://doi.org/10.1186/s12859-017-1934-z

Lin-Vien D, Colthup NB, Fateley WG, Grasselli JG (1991) The handbook of infrared and Raman characteristic frequencies of organic molecules. Elsevier, San Diego, California, USA

Allen E, Smith P (2001) A review of particle agglomeration. Surfaces 85(86):87

Berggren A, Palmqvist AE (2008) Particle size control of colloidal suspensions of mesostructured silica. J Phys Chem C 112(3):732–737

Vreugdenhil A, Balbyshev V, Donley M (2001) Nanostructured silicon sol-gel surface treatments for Al 2024-T3 protection. J Coat Technol 73(915):35–43

Wang D, Bierwagen GP (2009) Sol–gel coatings on metals for corrosion protection. Prog Org Coat 64(4):327–338

Metroke TL, Gandhi JS, Apblett A (2004) Corrosion resistance properties of Ormosil coatings on 2024-T3 aluminum alloy. Prog Org Coat 50(4):231–246

Zheng S, Li J (2010) Inorganic–organic sol gel hybrid coatings for corrosion protection of metals. J Sol Gel Sci Technol 54(2):174–187

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

All co-authors have been informed and consent to the publication.

Rights and permissions

About this article

Cite this article

Shetranjiwalla, S., Vreugdenhil, A. & Stotesbury, T. Waterborne epoxy-thiol decorated silica sol-gel coatings: impact of crosslinking on corrosion prevention. J Sol-Gel Sci Technol 87, 504–513 (2018). https://doi.org/10.1007/s10971-018-4739-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4739-2