Abstract

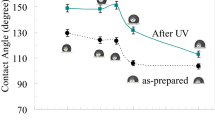

Superhydrophilic surfaces without the need of other stimuli are usually realized by constructing a rough morphology. However, constructing rough surfaces usually require specialized equipment or complicated processing. Besides, rough surfaces can cause undesirable scattering, which strongly limits the use in optical devices. In this article, we prepared superhydrophilic TiO2 films with ultra-smooth surfaces using simple sol-gel dip-coating method. The hydrophilicity of the TiO2 films varied with different post-heat treatments. The films heat-treated at 400 °C exhibited a durable superhydrophilicity and anti-fogging property. This superhydrophilicity was attributed to the decrease of surface hydrophobic alkoxy groups and the formation of point defects, i.e., Ti3+ and oxygen vacancies, which are favourable for dissociative water adsorption. The amount of surface organic groups was influenced by autophobicity effects, further hydrolysis and decomposition of residual alkoxy groups. Additionally, the wettability behaviours of the films were also explained from the perspective of the surface energy. These results can benefit the design and manufacture of anti-fogging and self-cleaning superhydrophilic TiO2 films.

The TiO2 films exhibited intrinsic superhydrophilicity and anti-fogging property; the superhydrophilicity can maintain 30 days.

Highlights

-

The TiO2 films exhibited durability, superhydrophilicity and anti-fogging property.

-

The superhydrophilicity films with smooth surface were capable of being optical materials.

-

The mechanism of the superhydrophilicity was well studied.

Similar content being viewed by others

References

Saxena N, Naik T, Paria S (2017) J Phys Chem C 121:2428–2436

Shi H, He Y, Pan Y, Di H, Zeng G, Zhang L, Zhang C (2016) J Memb Sci 506:60–70

Faustini M, Grenier A, Naudin G, Li R, Grosso D (2015) Nanoscale 7:19419–17425

Fujima T, Futakuchi E, Tomita T, Orai Y, Sunaoshi T (2014) Langmuir 30:14494–14497

Wang R, Hashimoto K, Fujishima A, Chikuni M, Kojima E, Kitamura A, Shimohigoshi M, Watanabe T (1997) Nature 388:431–432

Sakai N, Fujishima A, Watanabe T, Hashimoto K (2003) J Phys Chem B 107:1028–1035

Fujishima A, Zhang X, Tryk D (2008) Surf Sci Rep 63:515–582

Park JJ, Kim DY, Latthe SS, Lee JG, Swihart MT, Yoon SS (2013) ACS Appl Mater Interfaces 5:6155–6160

Diebold U (2003) Surf Sci Rep 48:53–229

Bharti B, Kumar S, Kumar R (2016) Appl Surf Sci 364:51–60

Yao L, He J (2014) J Mater Chem A 2:6994–7003

Wenzel RN (1949) J Phys Colloid Chem 53:1466–1467

Song S, Jing L, Li S, Fu H, Luan Y (2008) Mater Lett 62:3503–3505

Wang J, Wang JJ, Sun Y-L, Wang C-W (2013) J Sol-Gel Sci Technol 68:75–80

Huang W, Chen Y, Yang C, Situ Y, Huang H (2015) Ceram Int 41:7573–7581

Kumar R, Singh RK, Kumar M, Barthwal SK (2007) J Appl Polym Sci 104:767–772

Ebert J, Pannhorst H, Küster H, Welling H (1979) Appl Opt 18:818–822

Xiong Y, Lai M, Li J, Yong H, Qian H, Xu C, Zhong K, Xiao S (2015) Surf Coat Technol 265:78–82

Ashkarran AA, Mohammadizadeh MR (2008) Mater Res Bull 43:522–530

Zhang H, Liu Y, Wu Y, Ruan K (2015) J Nanosci Nanotechnol 15:2531–2536

Livage J, Henry M, Sanchez C (1988) Progress Solid State Chem 18:259–341

Vold MJ (1963) J Colloid Sci 18:684–695

Tan SN, Zeng X, Fokkink B (2013) Surf Eng 16:235–238

Vargas MA, Rodríguez-Páez JE (2017) J Non-Cryst Solids 459:192–205

Li X, He J (2013) ACS Appl Mater Interfaces 5:5282–5290

Di Mundo R, d’Agostino R, Palumbo F (2014) ACS Appl Mater Interfaces 6:17059–17066

Wang R, Hashimoto K, Fujishima A, Chikuni M, Kojima E, Kitamura A, Shimohigoshi M, Watanabe T (1998) Adv Mater 10:135–138

Lu GQ, Linsebigler A, Yates JT (1994) J Phys Chem 98:11733–11738

Henderson MA (1996) Surf Sci 355:151–166

Kumar R, Govindarajan S, Siri Kiran Janardhana RK, Rao TN, Joshi SV, Anandan S (2016) ACS Appl Mater Interfaces 8:27642–27653

Song Z, Hrbek J, Osgood R (2005) Nano Lett 5:1327–1332

Yu J, Zhao X, Zhao Q (2000) Thin Solid Films 379:7–14

Pouilleau J, Devilliers D, Groult H, Marcus P (1997) J Mater Sci 32:5645–5651

Dupin J-C, Gonbeau D, Vinatier P, Levasseur A (2000) Phys Chem Chem Phys 2:1319–1324

Naldoni A, Allieta M, Santangelo S, Marelli M, Fabbri F, Cappelli S, Bianchi CL, Psaro R, Dal Santo V (2012) J Am Chem Soc 134:7600–7603

Zuo F, Wang L, Wu T, Zhang Z, Borchardt D, Feng P (2010) J Am Chem Soc 132:11856–11857

Tauc J, Grigorovici R, Vancu A (1966) Phys Status Solidi 15:627–631

Tanemura S, Miao L, Jin P, Kaneko K, Terai A, Nabatova-Gabain N (2003) Appl Surf Sci 212–213:654–660

Justicia I, Ordejon P, Canto G, Mozos JL, Fraxedas J, Battiston GA, Gerbasi R, Figueras A (2002) Adv Mater 14:1399–1402

Owens DK, Wendt RC (1969) J Appl Polym Sci 13:1741–1748

Kong F, Xia Y, Jiao X, Chen D (2017) New J Chem 41:7562–7570

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Informed consent

Informed consent was obtained from all individual participants included in the study. This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Li, Y., Xia, B. & Jiang, B. Thermal-induced durable superhydrophilicity of TiO2 films with ultra-smooth surfaces. J Sol-Gel Sci Technol 87, 50–58 (2018). https://doi.org/10.1007/s10971-018-4684-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4684-0