Abstract

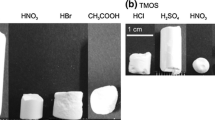

Macroporous gels with bicontinuous morphology in micrometer range were prepared in a titania–silica system containing 5 and 7.6 mass % titania using tetraethoxysilane and four kinds of Ti precursors, two titanium alkoxides, titanium chloride and titanium sulfate, under coexistence of poly(ethylene glycol) (PEG) with an average molecular weight of 20,000. In all the systems with different Ti precursors, the addition of PEG induced phase separation, and the macroporous morphology was formed when the transitional structure of phase separation was frozen-in by sol–gel transition of inorganic components. However, we can see large differences in phase separation tendency and Ti dispersion in silica network depending on the Ti precursors used. When titanium alkoxides were added into pure silica sol–gel system, phase separation tendency largely decreased, so that low temperature reaction was necessary for macropore formation. When we used titanium salts, on the other hand, phase separation tendency does not change much from pure silica system. The difference has been tentatively attributed to the difference in the mixing level of Ti in silica network. Although titania tended to aggregate when titanium alkoxides were used as precursors, Ti could be well dispersed in silica gel matrix when acetylacetone was added in the alkoxide system or when titanium salts were used as Ti precursors.

Similar content being viewed by others

References

Takahashi R, Nakanishi K, Soga N (1998) J Ceram Soc Jpn 106:772–777

Takahashi R, Sato S, Sodesawa T, Suzuki K, Tafu M, Nakanishi K, Soga N (2001) J Am Ceram Soc 84(9):1968–1976

Nishihara H, Mukai SR, Fujii Y, Tago T, Masuda T, Tamon H (2006) J Mater Chem 16(31):3231–3236

Tokudome Y, Miyasaka A, Nakanishi K, Hanada T (2011) J Sol–Gel Sci Technol 57:269–278

Hoffmann F, Cornelius M, Morell J, Fröba M (2006) J Nanosci Nanotechnol 6(2):265–288

Cho EB, Kim D, Jaroniec M (2007) Langmuir 23(23):11844–11849

Vaudreuil S, Bousmina M, Kaliaguine S, Bonneviot L (2001) Microporous Mesoporous Mater 44–45:249–258

Takahashi R, Sato S, Sodesawa T, Kawakita M, Ogura K (2000) J Phys Chem B 104:12184–12191

Nakanishi K, Tanaka N (2007) Acc Chem Res 40:863–873

Nakanishi K (1997) J Porous Mater 4:67–112

Nakanishi K, Takahashi R, Nagaakane T, Kitayama K, Koheya N, Shikata H, Soga N (2000) J Sol–Gel Sci Technol 17:191–210

Tokudome Y, Nakanishi K, Kanamori K, Fujita K, Akamatsu H, Hanada T (2009) J Colloid Interface Sci 338:506–513

Takahashi R, Sato S, Tomiyama S, Ohashi T, Nakamura N (2007) Microporous Mesoporous Mater 98:107–114

Tanaka N, Kobayashi H, Nakanishi K, Minakuchi H, Ishizuka N (2001) Anal Chem 73:420A–429A

Cabrera K (2004) J Sep Sci 27:843–852

Konishi J, Fujita K, Nakanishi K, Hirao K, Morisato K, Miyazaki Sh, Ohira M (2009) J Chromatogr A 1216:7375–7383

Himaguchi T (2001) Catal Surv Jpn 5:59

Beck C, Mallat T, Burgi T, Baiker A (2001) J Catal 204:428–439

Konishi J, Fujita K, Nakanishi K, Hirao K (2006) Chem Mater 18:6069–6074

Takahashi R, Sato S, Sodesawa T, Yabuki M (2001) J Catal 200:197–202

Takahashi R, Nakanishi K, Soga N (1997) J Sol–Gel Sci Technol 8:71–76

Takahashi R, Sato S, Sodesawa T, Kato M, Yoshida S (2000) J Sol–Gel Sci Technol 19:715–718

Takahashi R, Sato S, Sodesawa T, Arai K, Yabuki M (2005) J Catal 229:24–29

Nakamura N, Takahashi R, Sato S, Sodesawa T, Yoshida S (2000) Phys Chem Chem Phys 2:4983–4990

Sato S, Takahashi R, Sodesawa T, Kobata M (2005) Appl Catal A:Gen 284:247–251

Yabuki M, Takahashi R, Sato S, Sodesawa T, Ogura K (2002) Phys Chem Chem Phys 4:4830–4837

Zhu H, Pan Z, Chen B, Lee B, Mahurin SM, Overbury SH, Dai S (2004) J Phys Chem B 108:20038–20044

Tang J, Liu J, Yang J, Feng Z, Fan F, Yang Q (2009) J Colloid Interface Sci 335:203–209

Kim WI, Hong IK (2003) J Ind Eng Chem 9(6):728–734

Melero JA, Arsuaga JM, Frutos PG, Iglesias J, Sainz J, Blazquez S (2005) Microporous Mesoporous Mater 86:364–373

Zhang WH, Lu JQ, Han B, Li MJ, Xiu JH, Ying PL, Li C (2002) Chem Mater 14:3413–3421

Liu G, Liu Y, Yang G, Li S, Zu Y, Zhang W, Jia M (2009) J Phys Chem C 113:9345–9351

Chena HJ, Wang L, Chiu WY (2007) Mater Chem Phys 101:12–19

Brinker CJ, Scherer GW (1990) Sol–gel science. The physics and chemistry of sol–gel processing. Academic Press, New York

Rupp W, Husing N, Schubert U (2002) J Mater Chem 12:2594–2596

Lenza RFS, Vasconcelos WL (2002) Mater Res 5:497–502

Nakanishi K, Motowaki S, Soga N (1992) Bull Inst Chem Res Kyoto Univ 70:144–151

Nakanishi K, Komura H, Takahashi R, Soga N (1994) Bull Chem Soc Jpn 67:1327

Nakanishi K, Soga N (1997) Bull Chem Soc Jpn 70:587–592

Chen X, Mao SS (2007) Chem Rev 107:2891–2959

Takahashi R, Sato S, Sodesawa T, Suzuki M, Ogura K (2000) Bull Chem Soc Jpn 73:765–774

Rouquerol F, Rouquerol J, Sing K (1999) Adsorption by powders and porous solids. Academic Press, San-Diego

Acknowledgments

This study was financially supported by Industrial Research Grant Program in 04A25503c from New Energy and Industrial Technology Development Organization (NEDO) of Japan and the Grant-in-Aid for Scientific Research C (21560700) from the Japan Society for the Promotion of Science. O. R. appreciates deeply the research fellowship from Matsumae International Foundation, Japan (09G09).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ruzimuradov, O., Nurmanov, S., Kodani, Y. et al. Morphology and dispersion control of titania–silica monolith with macro–meso pore system. J Sol-Gel Sci Technol 64, 684–693 (2012). https://doi.org/10.1007/s10971-012-2903-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-012-2903-7