Abstract

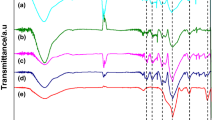

A series of UV-curable nanocomposite coating materials were prepared by sol–gel technique from tetraethoxysilane (TEOS), methacryloxypropyltrimethoxysilane (MAPTMS) in the presence of urethane acrylate resin based on polyethylene glycol 400 (PEG400). The sol–gel precursor content in the hybrid coatings was varied from 0 to 30 wt.%. In addition, acrylated phenylphosphine oxide oligomer (APPO) is replaced with urethane acrylate resin in order to investigate its effect on the nanocomposite property. The physical and mechanical properties such as; gel content, hardness, adhesion, gloss, impact strength as well as tensile strength were examined. Results from these measurements showed that all the properties of the hybrid coatings improved effectively by gradual increase in sol–gel precursor and APPO resin content. The real time infrared technique was used to follow the degree of acrylic double bond conversion. The thermal stabilities of the UV-cured nanocomposites were investigated by thermogravimetric analysis. The results revealed that the addition of sol–gel precursor and APPO oligomer into the organic network leads to an improvement in the thermal and flame resistance properties of the hybrid materials. It was also determined that the APPO containing hybrid coating with 20 wt.% silica content gave higher char yield than the coating without APPO. It is a desirable achievement to improve simultaneously both the flame retardancy and mechanical properties of a protective coating. SEM studies indicated that inorganic particles were dispersed homogenously through the organic matrix. The hybrids were nanocomposite. It was also found that, incorporation of APPO resin might govern the silica organization and this leading to formation of nanofibrillar structure.

Similar content being viewed by others

References

Wu S, Sears MT, Soucek MD, Simonsick WJ (1999) Polymer 40:5675

Huang HH, Orler B, Wilkes GL (1987) Macromolecules 20:1322

Haas KH, Walter H, Opin C (1999) Solid State Mater Sci 4:571

Brinker CJ, Scherer GW (1985) J Non-Cryst Solids 70:301

Brennan AB, Wikes GL (1991) Polymer 32:733

Kickelbick G. (2003) Prog Polym Sci 28:114

Qui W, Luo Y, Chen F, Duo Y, Tan H (2003) Polymer 44:5321

Judeinstein P, Sanchez C (1996) J Mater Chem 6:511

Bakthavatehalam Y, White Car CK (1990) Chem Mater 2:337

Wouters MEL, Wolfs DP, Vander Linde MC, Hovens JHP, Tinnemans AHA (2004) Progr Org Coat 51:312

Gilberts J, Tinnemans AHA (1998) J Sol–gel Sci Technol 11:153

Zong Z, He J, Soucek D (2005) Progr Org Coat 53:83–90

Radhakrishnan S, Pethrick RA (1994) J Appl Polym Sci 51:863

Boogers JAF, Klaase P, Devlieger JJ, Alkema DPW, Tinnemans AHA (1994) Macromolecules 27:197

Decker C, Moussa K (1993) J Coat Tech 65:49

Masson F, Decker C, Jaworek T, Schwalm R (2000) Progr Org Coat 39:115

Wang GA, Wang CC, Chen CY (2006) Polym Degr Stab 91:2683–2690

Wang Q, Shi W. (2006) Euro Polym J 42:2261–2269

Liang H, Shi W (2004) Polym Degr Stab 84:525–532

Chiang CL, Ma MCC (2002) Euro Polym J 38:2219–2224

Chiang CL, Ma MCC, Wang FY, Kuan HC. (2003) Euro Polym J 39:825–830

Wang DY, Ge XG, Wang YZ, Wang C, Qu MH, Zhou Q (2006) Macromol Mater Eng 291:638–645

Camino G, Tartaglione G, Franche A, Manferti C, Finocchiaro P, Falqui L (2006) Fire Polymers IV: Materials and Concepts for Hazard Prevention ACS Symposium Series 922:21–35

Karataş S, Hoşgör Z, Menceloğlu Y, Kayaman-Apohan N, Güngör A (2006) J Appl Polym Sci 102:1906–1914

Kayaman-Apohan N, Demirci R, Çakır M, Güngör A (2005) Rad Phys Chem 73:254–262

Smith CD, Grubbs H, Webster HF, Güngör A, Wightman J, McGrath JE (1991) High Perform Polym 3:211

Yılmaz-Inan T, Ekinci E, Yıldız E, Kuyulu A, Gungor A (2001) Macromol Chem and Phys 202:532–540

Kahraman MV, Kuğu M, Menceloğlu Y, Kayaman-Apohan N, Güngör A (2006) J Non Cryst Solids 352:2143–2151

Karataş S, Kızılkaya C, Kayaman-Apohan N, Güngör A (2007) Progr Org Coat 60:140

Ni H, Simonsick WJ, Skaja AD, Williams JP, Soucek MD (2000) Progr Org Coat 38:97

Lee YJ, Gungor A, Yoon TH, McGrath JE (1995) J Adhesion 55:165–177

Zandi-Zand R, Ershad-Iangroudi A, Rahimi A (2005) J Non Cryst Solids 351:1307–1311

Wicks ZW, Jones FN, Pappas SP (1975) Org Coat Sci and Tech, vol 1. Wiley, New York

Tasic S, Bozic B, Dunzie B (2004) Prog Org Coat 51:321–328

Subramani S, Choi SW, Lee JY, Kim JH (2007) Polymer 48:4691–4703

Xu J, Pang W, Shi W (2006) Thin Solid Films 514:69–75

Huang Z, Shi W (2006) Euro Polym J 42:1506–1515

Wang H, Xu P, Meng S, Zhong W, Du W, Du Q (2006) Polym Degr Stab 91:1455

Acknowledgements

This work was supported by Marmara University, Commission of Scientific Research Project under grant FEN-YLS-100105–0053 and also partially supported by TUBITAK Research Project under grant 106T083. The authors would like to thank Assoc. Prof. Dr. Yusuf Menceloğlu and Burçin Yıldız for 29Si-NMR and 31P-NMR measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Apohan, N.K., Karataş, S., Bilen, B. et al. In situ formed silica nanofiber reinforced UV-curable phenylphosphine oxide containing coatings. J Sol-Gel Sci Technol 46, 87–97 (2008). https://doi.org/10.1007/s10971-008-1709-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-008-1709-0