Abstract

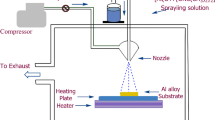

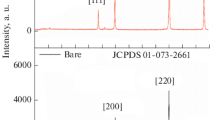

Multilayered alumina film was deposited onto metallic substrate using cycles of dip-coating method. The film thickness was found not always growing linearly with the increase of the number of dipping cycles, and even a zero-growth in thickness was observed after 20 cycles of dip coatings. This phenomenon was found to be attributed to the dissolving behavior of alumina gel material in original sol. A heat treatment at a temperature higher than 230 °C was found to be able to effectively lower the dissolvability of Al2O3 gel material, but an extra high temperature, i.e., 600 °C led to the formation of cracks in the multilayered film due to the increase of interfacial tension force. It was examined by IR and XRD analyses that a heat treatment at 250 °C for 10 min before each coating process could yield an amorphous multilayered film with no crack formed after calcinations at 600 °C. A crack-free Al2O3 film with a thickness up to 2 μm after 22 cycles of dip coating process could be produced and it showed an excellent antioxidation performance for steel substrate.

Similar content being viewed by others

References

Kobayashi Y, Ishizaka T, Kurokawa Y (2005) J Mater Sci 40:263

Emmerich R, Enders B, Martin H, Stippich F (1997) Surf Coat Techol 89:47

Rsveh A, Tsameret ZK, Grossman E (1996) Surf Coat Techol 88:103

Reisfeld R, Saraidarov T (2006) Opt Mater 28:64

Jing CB, Hou JX, Zhang YH (2006) J Phys D, Appl Phys 39:1174

Yu JG, Yu JC, WK H, Jiang ZT (2002) New J Chem 26:607

Chen YC, Al X, Huang CZ (2000) Mater Sci Eng B 77:221

Ishizaka T, Kurokawa Y, Makino T, Segawa Y (2001) Opt Mater 15:293

Fu Q, Cao CB, Zhu HS (1999) Thin Solid Films 348:99

Wright JD, Sommerdijk JM (2001) In: Sol-gel materials chemistry and applications. Gordon and Breach Science, Singapore, p 1

Olding T, Sayer M, Barrow D (2001) Thin Solid Films 398–399:581

Ono S, Tsuge H, Nishi Y, Hirano SI (2004) J Sol-Gel Sci Technol 29:147

Drabarek E, Finnie KS, Bartlett JR, Woolfrey JL, Mitchell D (1998) Ceram Trans 81:119

Lombardi T, Klein LC (1998) Adv Ceram Mater 3:167

Kozodoy RL, Harrington JA (1995) Appl Opt 34:7840

Kozuka H, Kajimura M, Hirano T, Katayama K (2000) J Sol-Gel Sci Technol 19:205

Kozuka H, Kajimura M (2000) J Am Ceram Soc 83:1056

Kozuka H, Higuchi A (2003) J Am Ceram Soc 86:33

Jing CB, Zhao XJ, Tao HZ, Wang XN, Liu AY (2003) J Mater Chem 13:3066

Pierre AC (1998) Introduction to sol-gel processing. Kluwer Academic, London, p 93

Acknowledgments

This work was financially supported by the Key Project of Wuhan City for International Cooperation, P.R. China No. 981001009, Program for Changjiang Scholars and Innovative Research Team in University (PCSIRT), and the Doctoral Fund of Qingdao University of Technology & Science, P.R. China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jing, C., Zhao, X. & Zhang, Y. Elimination of a zero-growth in thickness of Al2O3 protective film deposited by cycles of dip-coating method. J Sol-Gel Sci Technol 42, 151–156 (2007). https://doi.org/10.1007/s10971-007-1533-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-007-1533-y