Abstract

Nano ZnO is biosynthesized using Lactobcillus sp. Poly Acrylic acid-co-Acrylonitrile/ZnO, PAACAN/ZnO, and poly Acrylic acid-co-Maleic acid/ZnO, PAACMA/ZnO, nancomposites were synthesized using 60Co γ-rays. PAACAN/ZnO and PAACMA/ZnO nanocomposites were characterized and used as sorbents for 60Co(II) radionuclide. The monolayer adsorption capacities of 60Co(II) onto PAACMA/ZnO and PAACAN/ZnO are 18.235, 7.105 mgg−1, respectively at pH 4.5 and 20 °C. The sorption reaction has a pseudo 2nd order mechanism. 0.1 M EDTA could be used as an eluent for desorption. The desorption efficiencies of 60Co(II) from PAACAN/ZnO and PAACMA/ZnO were 67.51 and 84.85%, respectively. The sorption process is endothermic and spontaneous.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Radioactive waste is considers as an obstacle for scientists all over the world. It needs special management in order to prevent unnecessary effects on the society and the environment [1]. 60Co, in concert consider as one of the radioactive wastes generated from nuclear reactors, may be present in trace amounts in the environment [2, 3]. It decays by gamma radiation and has a relatively long half-life (t1/2 = 5.27 years). External and internal exposure to 60Co can increase cancer risk. Hence, there is a need for a suitable and economically method to eliminate that exposure.

Adsorption [4] is the simplest, most efficient, and most economical method that could be used for radioactive waste treatment. Selecting a suitable adsorbent for such treatment is the main step in the treatment process [5]. Several adsorbents such as activated and impregnated carbon [6], clay [7], aluminosilicates [8], organic and inorganic gels [9] and others have been reported as adsorbents for radioactive waste. Organic composites have much greater interest than inorganic composites especially in industrial applications because they have a higher capacity than inorganic resin.

PolyAcrylic acid (PAA) is an important water sorption and low cost polymer having ionizable hydrophilic properties. The active functional group COOH is responsible for its sorption properties [10].

Even so, due to the poor mechanical characteristics and thus insufficient physical, chemical, or mechanical bonding of polymer chains, the use of PAA is still restricted, especially in the field of tissue engineering [11]. The implementation of artificial cross linkers such as N,N′-methylenebisacrylamide (DAM) for the formation of a polymeric network through the formation of several covalent cross linking points is a common trend for modifying the mechanical properties of PAA. Furthermore, the ease of fabrication, reinforcing techniques based on the incorporation of functionalized nonmaterials as additives or filler materials, such as clay [12], silica nanoparticles [13], carbon nanotubes [14], ferritin particles [15], and graphene oxide [16], the interest of researchers have piqued to prepare nanocomposite materials.

Nano-materials have huge applications for wastewater treatment based totally on the adsorption principle. In comparison to bulk particles, nanoparticles have a higher surface area, more adsorption sites, higher adsorption specificity, high permeability, high chemical stability, lower toxicity and a lower price [17]. The usage of polymer grafted nano metal oxides for the elimination of toxic heavy metals from wastes has continued to attract extensive interest in recent years [18].

Nano ZnO (ZnONPs) is regarded as a good sorbent [19] due to its low cost and non-toxicity. Sol gel techniques [20], wet chemical method [21], green chemistry [22], and microwave-assisted method [23] have all been used to prepare ZnONPs. Chemical and physical methods are quite expensive and require a significant amount of labour and time. The biosynthesis of nano zinc oxide (ZnO NPs) from plants, fungi, and bacteria such as E.coli and Lactobacillus [24] are still a research topic.

Hydrophilic nature as well as good electro-chemical characteristics adequate for adsorption can be influenced through grafting water soluble monomers onto hydrophobic polymers. For grafting modifications, γ-ray and electron beam radiations are widely used as high-energy radiation, and gamma rays are more dominant [25].

In Jiao et al. [26], Poly (acrylic acid-co-maleic acid) was used for the recovery of copper from synthetic aqueous with a yield of 99.84%. Water-soluble transition metal salts were used as catalysts for the polymerization of maleic acid with a water-soluble initiator [27].

This work aims to biosynthesize of ZnO NPs by bacterial culture Lactobcillus sp. for the preparation of two novel nanocomposites; poly (Acrylic acid-co-Acrylonitrile)/ZnO (PAACAN/ZnO) and poly (Acrylic acid-co-Maleic acid)/ZnO (PAACMA/ZnO) by using gamma irradiation of 60Co with a dose of 25 KGy. The prepared nanocomposites used as sorbents for 60Co(II) radionuclide from radioactive waste. PAACAN/ZnO and PAACMA/ZnO nanocomposites characterized by FT-IR, DTA-TGA, SEM, and porosity measurements. pH, contact time, metal ion concentration, ionic strength, and sorbent weight were all studied as influencing factors in the sorption process. The mechanism of the sorption reaction is suggested by evaluating the fit of various kinetic and adsorption isotherm models.

Experimental

Materials and procedure

Bacterial strain

Bacterial cultivation Lactobcillus sp. was obtained from the Microbiology Laboratory, Soil and Water Research Department, Nuclear Research Centre, Atomic Energy Authority, Inshas, Egypt, for the biosynthesis of ZnO NPs. The bacteria were grown on de Man, Rogosa, and Sharp (MRS) agar medium (g L−1) containing meat peptone 10, meat extract 10, yeast extract 5, glucose 20, dipotassium hydrogen phosphate 2, diammonium hydrogen citrate 2, sodium acetate trihydrate 5, magnesium sulphate heptahydrate 0.2, manganese sulphate tetrahydrate 0.05 agar 15, and 1L of dist. water.

Synthesized of nano ZnO

Lactobcillus sp. was grown on de Man, Rogosa, and Sharp (MRS) broth medium, which holds the immediately preceding mixture medium with no agar. The pH was adjusted to 5.4 before pure culturing of Lactobcillus sp. and incubated aerobically for 24 h at 100 rpm on a rotary shaker at 37 °C. The culture solution was diluted four times with sterile distilled water and allowed to grow for another 24 h. Figure 1a–c. After the incubation stage, the pH was adjusted to 6.0 using 0.4 M NaOH to delay the process of transformation. The mixture was then treated with 0.1 M ZnSO4·H2O. The temperature is raised to 80 °C by heating the prepared mixture on water bath. A white precipitate appears at the bottom of flask indicates the hydrolysis of ZnSO4·H2O to hydrous zinc oxide [28] according to chemical Eq. (1)

Synthesize of nano ZnO by Bacterial culture Lactobcillus sp. a, b Macroscopic image of Lactobacillus sp., c macroscopic image of Lactobacillus sp. gram stain under light microscope with magnification power of 10X100. d ZnO NPs deposited at the bottom of the flask. e ZnO NPs was accumulated by centrifugation and washed with deionised water followed by drying at 40 °C in a hot air oven for 4 h. f UV–visible spectrum of ZnO nanoparticles

The flask was removed from water bath and incubated at 37 °C for 12 h then the particles would get deposited at the bottom of the flask (Fig. 1d, e). The product was accumulated by centrifugation and washed with deionised water followed by drying at 40 °C in a hot air oven for 4 h and calcinied at 300 °C/6 h [28]. Hydrolysis of ZnSO4 to hydrous zinc oxide NPs was demonstrated by UV–Visible spectrum in the range 300–600 (Fig. 1f). It exhibits a strong absorption band at about 355 nm [29] and a monodispersed nature of the nanoparticle distribution.

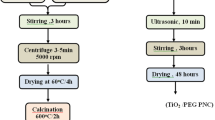

Synthesized of PAACAN/ZnO and PAACMA/ZnO nanocomposites

In Group A, various molar ratios of acrylic acid (AA), acrylonitrile (AN), and calcined nano ZnO were copolymerized in the presence of methylene bis acrylamide (DAM) as a cross-linker to synthesise (PAACAN/ZnO) nanocomposites. In 80 ml deoxygenated water, AA, AN, and calcined ZnO Nps were mixed in the presence of DAM. At room temperature, the mixture is stirred for 4 h. The mixture was subjected to 25 KGy of gamma irradiation at a dose rate of 689.538 Gy/h using a cobalt-60 gamma cell 220 at the EAEA’s cyclotron facility. The preceding steps were repeated to create PAACMA/ZnO nanocomposites, while different molor ratios of AA and maleic acid (MA), as shown in Table 1 (Group B), were copolymerized with calcined nano ZnO and DAM. The materials were cut into small pieces and soaked in acetone for 2 h to eradicate water and un-reacted monmers before being dried in a vacuum oven at 333 K for 24 h and sieved to size (< 250 µm).

Instruments

Investigation of the surface morphology of the nanocomposites carried out by scanning electron microscope (SEM) combined with energy-dispersive X-ray spectroscopy, backscatter diffraction (SEM, Philips XL 30 ESEM (25–30 keV accelerating voltage, 1–2 mm beam diameter and 60–120 s counting time) and The transmission electron micrograph image, TEM, for the particle size was recorded on a TEM, JEM2100, Jeol.s.b, and (Japan). The effective functional groups recognized by Fourier transform infrared spectra (FT-IR) (KBr pellet technique on a Perkin Elmer 1600 FTIR Spectrophotometer in wave number range 400–4000 cm−1). The phase structures were determined by (XRD) (Philips X'PERT multipurpose X-ray diffractometer with copper emission lines). Porosity measurements are determined using pore size analyzer 9320. The activity is measured radiometrically by high resolution (7.5%) NaI (TI) detector model 802-3XE, Canberra, (USA).

Point of zero charge

The point of Zero charge pH (ZPC) is the point at which the surface charge of the sorbent is equal zero. At pH lower than this point, the surface charge is positive and after this point, the surface charge is negative. The efficient sorbents for cations have low value of point of Zero charge because the surface of charge is negative at a wide range of pH. The point of zero charge determined by batch technique using 0.1 g of the nanocomposites with 10 mL of 0.1 M NaCl and the solution shaked for 24 h at 20 °C at different pH range from 1 to 11. Finally, the pH is measured after shaking and point of Zero charge determined by plotting pHi against ∆ pH (pHf−pHi). The point intersect the x-axis (pHi) is the point of zero charge [30].

Sorption studies

A stock solution of (Stable Co(II) were prepared by dissolving of amount of cobalt chloride with initial concentration (C0 = 100 mg L−1) in double-distilled water and spiked with the 60Co radionuclides (A0 = 100 KBq/L). These solutions were kept as stock radioactive solutions for all experiments. The sorption behaviour of 60Co(II) onto (P5AACAN/ZnO) and P5AACMA/ZnO) nanocomposites were studied. Variation of the sorption parameters performed to maintain the optimum sorption conditions. i.e. pH (2–8), contacts time (5–4320 min), initial concentration (50–300 mg L−1), Temperature (20–60 °C) and sorbent dose (0.02–0.2 g). Samples were filtered and thus separated from the solution.

The Removal percentage of 60Co(II) radionuclide at each interval of time is given by Eq. (2):

Sorbed amount q (mgg−1) is calculated using Eq. (3):

where Ao and Ae are the initial and equilibrium concentrations of the 60Co(II) radionuclide, m is the mass of the P5AACAN/ZnO or P5AACAM/ZnO nanocomposites (g) and V volume of solution (L). The distribution coefficient Kd (mLg−1) given by Eq. (4).

Kinetic modeling

Three kinetic modelling fitting investigated to suggest a possible mechanism for the sorption reaction; Pseudo 1st order [31], pseudo 2nd order [32] and Elovich model [33, 34]

The pseudo 1st order equation is given by Eq. (5):

where qe and qt are the sorbed amounts of 60Co(II) ions; (mgg−1) at equilibrium time and at any time t, respectively; k1 (min−1) is the pseudo 1st order rate constant.

The pseudo 2nd order is described by the Eq. (6) [32]:

where k2 (gmg−1 min−1) is the pseudo 2nd order rate constant.

The surface coverage and activation energy are indicated in Elovich Eq. (7)

where α, β are the Elovich constants. α (mgg−1 min−1) is the rate of chemisorptions at zero coverage, whereas β (gm g−1) is the extent of surface coverage and chemisorption activation energy.

Isotherm modeling

Langmuir [35], Freundlich [36] and Temkin isotherm [37] are utilized during this work Langmuir isotherme model applied by Eq. (8)

where qmax is the monolayer sorption capacity (mg g−1), b sorption free energy constant and Ce is the metal ion concentration at equilibrium. The separation factor calculated from Langmuir constant

As the value of RL gives an indication that, the isotherm type is linear (RL = 1), irreversible (RL = 0), unfavourable (RL > 1) or favourable (0 < RL < 1).

The linear Eq. (10) represents Freundlich model

where Kf denotes for Freundlich constants, and n denotes for sorption capacity and intensity.

Temkin considers that the sorption heat varies linearly with the degree of overlap. The following is the model: Eq. (11):

where AT is the maximal binding energy (Lmol−1), bT is the sorption heat, R is the universal gas constant (8.314 JK−1 mol−1), and T is the absolute temperature (K).

Thermodynamic parameters

Thermodynamic parameters can be calculated from the temperature dependent adsorption isotherms based on following equations [38] by applying Eqs. (12–15)

where γ is the coefficient of activity (dimensionless), [Adsorbate] ° is the standard concentration of the adsorbate (1 mol L−1) and K°e is the thermodynamic equilibrium constant that is dimensionless, Kg is the best isotherm model fitted.

The values of other thermodynamic parameters such as ΔHo (kJ mol−1) and ΔSo (J mol−1 K−1) have been calculated using the following Eq. (15):

where R is universal gas constant 8.314 J mol−1 K−1, and T is absolute temperature.el poly(acrylic acid)/nanosorbent embedded hydrog

Results and discussions

Characterization of the prepared nanocomposite

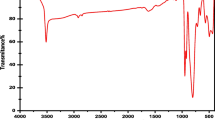

FT-IR analysis

Figure 2a–c represents the peaks corresponding to the existence functions groups of ZnO nanoparticles. Figure 2a for the spectra and functional group involved in ZnO NPs biosynthesis illustrated many peaks in the range of 500–3000 cm−1. Broad peak obtained at 3377 corresponded to OH stretching vibrations of water molecules. Weak peaks obtained at 2961, 2927, 2858 attributed to stretching vibration of the C–H bond. The sharp peaks obtained at 1649 corresponded to C=C stretch alkene group. Three weak peaks at 1547, 1446, and 1392 were correlated to the carboxylate group. The strong peaks at 945 cm−1 resulted from C–O stretching vibrations.). The band at 673 cm−1 could be related to the binding between sugar monomers. Figure 2a reveals the peak observed at 528 corresponds to the stretching vibrations of ZnO NPs [39].

The FTIR peaks related to P5AACAN/ZnO and P5AACMA/ZnO nanocomposites (Fig. 2b, c), respectively. The peak assigned at 3444 cm−1 belongs to the absorption O–H group [40] in both nanocomposites but the intensity at P5AACMA/ZnO nanocomposites is higher than its counterapart. The peaks at 1636 cm−1 related to C=C remaining of AA and AN monomers. Distinct peaks of ZnO appeared at 470 cm−1due to stretching vibration of Zn–O appeared in P5AACAN/ZnO and P5AACMA/ZnO nanocomposites. In P5AACAN/ZnO nanocomposite, a 2240 cm−1 due to C≡N and a peak around 1730 cm−1 attributed to C=O [41].

Particles morphology

Figure 3 depicts the particles morphology TEM of nano ZnO and SEM of P5AACAN/ZnO and P5AACMA/ZnO nanocomposites. TEM of Nano ZnO clarified the spherical agglomerated particles of nano ZnO [42], the average particle size is 16.04 nm. The small crystal size of the prepared ZnO is due to preferential erosion of ZnO crystal lattice [43]. The cracking layer surface clarifies the porous structure of P5AACAN/ZnO nanocomposite. The homogenous distribution ZnO is identified [44]. The micrographs taken at 10 µm clearly showed the ZnO incorporation in P5AACAN/ZnO. However, the micrograph of P5AACMA/ZnO nanocomposite shows well dispersed of nano ZnO. Aggregation of nano ZnO particles is noticeable.

X-ray diffraction (XRD)

Figure 4 includes the XRD pattern of calcinied ZnO nanoparticles, P5AACAN/ZnO and P5AACMA/ZnO nanocomposites. X-ray diffraction peaks of calcinied ZnO confirmed that the existing phase is Wurtzite phase and all the crystalline diffraction peaks with hexagonal phase consistent with the reported JCPDS data. The synthesized ZnO nanoparticle diameter was calculated using Debye–Scherrer formula using the diffraction peak intensity of (101):

where 0.9 is Scherrer’s constant k, λ is the wavelength of X-rays (CuKα-0.154 nm), θ is the Bragg diffraction angle, and β is the full width at half-maximum (FWHM) of the diffraction peak. The parameter calculation for average particle size of ZnO nanoparticle is shown in Table 2 The average particle size of the sample was found to be 25.16 nm. Nevertheless, it is concluded that ZnO is prepared at the nanoscale.

XRD of P5AACAN/ZnO and P5AACMA/ZnO nanocomposites show amorphous nature. The diffraction peaks of P5AACMA/ZnO nanocomposite are weaker and broader than P5AACAN/ZnO composite.

Porosity measurements

Table 3 includes the porosity measurements of P5AACAN/ZnO and P5AACMA/ZnO nanocomposites. The results indicate P5AACMA/ZnO nanocomposites had total pore area, porosity more than P5AACAN/ZnO nanocomposite. The average pore diameter (> 50 µm) for the two nanocomposite accounts for the presence of macropores. This means the cracking of the surface and a predication to higher removal percentage.

Sorption studies

The removal percentage (%) and sorbed amounts of nZnO, PAACAN/ZnO, and PAACMA/ZnO nanocomposites towards 60Co(II) are given in Table 4. It is observed that sorption efficiencies (%) and sorption amount of PAACAN/ZnO is less than that of PAACMA/ZnO nanocomposites this is due to the strong electron-withdrawing effect of the nitrile groups may have lowered the relative reactivity of PAACAN/ZnO [45]. However, the ionic carboxylate groups forms hydrogen bond with sorbed 60Co(II) [46] in PAACMA/ZnO nanocomposites result in high removal percentage.

The removal percentage of nZnO toward 60Co(II) is 26.35%. So, addition of different percentage of nZnO to PAACAN and PAACMA increase the removal percentage of the nano composites. Also, by increase mol % of nano ZnO in the two types of prepared composites, the removal percentage increases. This is due to adsorption of ionic polymer over the surface of the nano ZnO oxide particle imparting a high surface charge density and consequently an increase in the electrostatic attraction between nanocomposite and adsorbed 60Co(II) ions [46].

P5AACAN/ZnO and P5AACMA/ZnO show high removal percentage compared with the other compositions of the prepared samples. Thus, the nano-composites of P5AACAN/ZnO and P5AACMA/ZnO selected for the aim of the study. The parameters affecting the sorption reaction as pH, contact time, initial metal ion concentration, ionic strength and temperature is studied.

Impact of [H+] concentration

Hydrogen ion concentration affects sorption reaction greatly. Studying the impact of the change of pH on the sorption of 60Co onto P5AACAN/ZnO and P5AACMA/ZnO nanocomposites within (2–7.5) is shown in Fig. 5a. The sorption of 60Co is increased by raising the pH values from (2–4.5).

After pH 4.5 the increase in removal percentage belongs to Co (OH)2 precipitate rather than sorption of Co(II) and the differentiation between the amount of Co(II) adsorbed onto the nanocomposite and the precipitated amount become difficult. This is confirmed by the precipitation curve in Fig. 5b and Fig. 5c the speciation diagram of of Co(II) at different pH values in aqueous. It shows that 60Co(II) ions are presented at the optimum pH = 5; confirming that the 60Co(II) ions are sorbed as divalent species and at pH higher than 5; hydroxides started to appears [47]. The [H]+ compete 60Co(II) ions for °Ccupying the active sites as the value of pH is more acidic and thus the sorption of 60Co(II) is decreased. Increasing pH value led to a decrease in the competition. Therefore, the optimum pH value was chosen at pH = 4.5.

Figure 5d investigates point of zero charge (pHZPC). The estimated pHZPC are 4.01 and 2.8 for P5AACAN/ZnO and P5AACMA/ZnO nanocomposites, respectively. The optimum pH was chosen to be 4.5 for the two nanocomposites. The surface charge is positive at pH before 4.01 and 2.8 for P5AACAN/ZnO and P5AACMA/ZnO nanocomposites, respectively. At pH higher than pHZPC, the surface charge is negative so the sorption efficiencies increase after pH 4.01 and 2.8 for P5AACAN/ZnO and P5AACMA/ZnO nanocomposites, respectively. The lowest sorption efficiencies before this point were due to repulsion between surface of nanocomposites and radionuclides in addition to the competition of H+ as discussed previously. The higher sorption efficiencies of P5AACMA/ZnO nanocomposites than P5AACAN/ZnO are in agreement with pHZPC [48].

Impact of time

Figure 6 illustrates the impact of time studied of the the sorption of 60Co(II) onto P5AACAN/ZnO and P5AACMA/ZnO nanocomposites within the range (5–4320 min). The sorption equilibrium attained after 24 h. The sorbent amount increases gradually till the equilibrium time of the sorption process due to the accessible vacant active sites on the surface of the prepared nano-composites and high concentration of 60Co(II) at early time stage. The sorbed amount of 60Co(II) onto P5AACAN/ZnO and P5AACMA/ZnO nanocomposites at equilibrium time are 5.112 and 8.6005 mg g−1, respectively.

Impact of initial metal ion concentration and temperature

The amounts of 60Co(II) sorbed onto P5AACAN/ZnO and P5AACMA/ZnO nanocomposites as a function of initial ion concentration are given in Fig. 7. This figure shows that the amount sorbed increases by increasing 60Co(II) metal ion concentration. The removal percentage decrease from 65.93% for 60Co(II) ion concentration 50 mgL−1 to 22.28% with 60Co(II) ion concentration 300 mgL−1 for P5AACAN/ZnO nanocomposites at 293 K and from 88.06% for 60Co(II) ion concentration 50 mgL−1 to 54.26% with 60Co(II) concentration 300 mgL−1 for P5AACMA/ZnO nanocomposite at 293 K. This is due to the fixed number of active sites and at higher concentrations of 60Co(II), the driving force to P5AACAN/ZnO and P5AACMA/ZnO nanocomposites surface 60Co(II) interface increases till the active sites become saturated [49, 50]. However, the relation of the amounts of 60Co(II) sorbed onto P5AACAN/ZnO and P5AACMA/ZnO nanocomposites are not linear due to the interactions between the particles [51].

The sorption of 60Co(II) onto P5AACAN/ZnO and P5AACMA/ZnO nanocomposites are affected by temperature. Variation of temperatures from 20 to 60 °C was carried out for the applied concentration range 50–300 mg g−1 of 60Co(II) and pH 4.5. The effect of temperature on 60Co(II) sorption can be concluded from Fig. 10. The sorbed amount of 60Co(II) from aqueous solution was 88.05% and 65.932% at 293 °C for 50 mg g−1 and increased to 99.3% and 99.60% at 233 K onto P5AACMA/ZnO and P5AACAN/ZnO nanocomposite, respectively. The increase in removal efficiencies with the increase in temperature shows that the sorption processes have endothermic nature.

Impact of sorbent dose

Sorbent dose is an important parameter in the sorption process controls on the economics of the process. To examine the effect of sorbent dosage on 60Co(II) sorption, different weights from 0.02 to 0.2 g of nanocomposites P5AACAN/ZnO and P5AACMA/ZnO were used at temperature of 20 °C and contact time of 24 h for initial 60Co(II) concentration of 100 mgL−1. Experimental results plotted in Fig. 8 showed that the percentage of 60Co(II) removal increased from 54.2 to 86.4% for P5AACMA/ZnO and from 28.9 to 52.5% when the adsorbent dosage increased from 0.02 to 0.1 g and these behaviour related to the increase of available active sites. At higher dose of sorbent more than 0.1 g, the sorbed amount is nearly unchanged as the number of 60Co(II) ions in the solutions are not enough to completely combine with all active sites of the prepared nanocomposites [52].

Impact of ionic strength

Ionic strength effected the sorption of 60Co(II) onto P5AACAN/ZnO and P5AACMA/ZnO nanocomposites. The sorption experiment was conducted by equilibrating 0.1 g of the two nanocomposites with 100 mg/L of 60Co(II) and NaCl electrolytes with concentrations range from [0–102 mol L−1. Figure 9. Indicates that the sorbed amount decreased with increase in ionic strength of the NaCl salt solutions for the two prepared nanocomposites. The decrease in sorbed amount with increase in ionic strength is primarily attributed to the attraction affinity between Co(II) and Cl– ions and formation of CoCl2. That is, the amount 60Co(II) ions remaining in solution for sorption was reduced considerably and hence the low sorption of 60Co(II) in addition to competition of Na (I) for the sorption sites on the two nanocomposites. By the increase of NaCl concentration from 0 to 0.2 mol L−1, the removal percentage decreases from 86.18 to 24.45% and from 51.31 to 14.4% in P5AACMA/ZnO and P5AACAN/ZnO nanocomposites, respectively.

Kinetic modeling

Figure 10a shows the plot between t with log qe−qt. From the slope and the intercept of the linear relation, the constant of 1st equation k1 and the capacity of sorption process at equilibrium qe respectively could be determined. Table 5 lists the values of qe, k1, and the R2 of the 60Co(II). The straight line proposed the applicable of the pseudo 1st order model to convenient the experimental data during the adsorption process. Furthermore, the values of calculated capacity qe (cal.) must be resembled the values of the experimental qe (exp.). From Table 3 the values qe (cal.) are not in convenient with qe (exp.). So, it is obvious, the sorption of 60Co(II) onto the prepared nanocomposite do not fit pseudo1st model.

Figure 10b shows the linear plot of t/qt versus t for both nanocomposites. The coefficients of 2nd order model were listed in Table 3. The high values of R2 and the plot of t/qt with t elucidate that, the sorption of 60Co onto P5AACMA/ZnO and P5AACAN/ZnO nanocomposite regulated by pseudo 2nd order kinetics. Also, the values of qe (cal.) are resembled the results of qe (exp.). These proved the sorption are chemisorptions process.

Film diffusion or Intra particle diffusion models fitting to the surface of nano composite are observed in Fig. (10 c, d), where the linear plot of log (1−F) versus t in Fig. 10c has intercept and not equal zero. So, the sorption process is not controlled by film diffusion. The intra particle diffusion model is represented in Fig. 10d. The intra-particle diffusion kinetic model for the sorption process of the 60Co(II) occurred through three stages. The first stage expresses the diffusion of the 60Co(II) from the solution to the macropores or boundary surface of P5AACMA/ZnO and P5AACAN/ZnO nanocomposite (from 5 to 40 min) and it is very fast stage. The second stage (from 60 to 360 min) designs the gradual sorption on the surface of the P5AACMA/ZnO and P5AACAN/ZnO nanocomposite or diffusion to micropores of the nanocomposite, which may be the rate- limiting step. The third one (from 1440 to 4320 min) is the equilibrium saturation. Table 5 includes the parameters obtained from the second part of the linear plot.

The plot in Fig. 10e elucidate that the chemical sorption process performed on the heterogeneous surface of P5AACMA/ZnO and P5AACAN/ZnO nanocomposite and they are successfully confirmed the second-order kinetic. The values of R2 ≤ 0.8 assure the confirmation of this explanation.

Isotherm modelling

The equilibrium sorption isotherm is fundamentally important in the design of sorption system mechanisms. Isotherm modelling studied at 293, 313 and 333 K. The linear plot of Ce/qe versus Ce in Fig. 11a indicates the sorption process fitted with Langmuir postulates. Also, the high correlation coefficient, R2 = 0.96. qmax determined from the slope of the plot and listed in Table 4. The sorption capacity of 60Co(II) at 25 °C onto P5AACMA/ZnO and P5AACAN/ZnO nanocomposite are 18.248 and 7.107 mgg−1, respectively. Furthermore, the increase of the sorption capacity with temperature rising confirming the endothermic nature of sorption reaction. The processes are favourable because 0 < RL < 1 for the two nanocomposites. The sorption capacities of 60Co(II) onto P5AACMA/ZnO nanocomposite were 18.284, 18.587 and 18.857 mg g−1 at 293, 313 and 333 K, respectively on the other hand, The sorption capacities of 60Co(II) onto P5AACAN/ZnO nanocomposite were 7.107, 11.1098 and 15.477 mg g−1, respectively at the same temperatures.

Freundlich relation obtained by plotting log qe against log Ce, the straight lines had been obtained as shown in Fig. 11b. The values of Freundlich constants, n and k, are calculated from the slope and intercept, respectively, and represented in Table 6. The numerical of n > 1 suggested that P5AACMA/ZnO and P5AACAN/ZnO nanocomposite bind with a highest strength multiple binding sites of sorbent. The correlation coefficients of Langmuir isotherm model (R2 were higher than Freundlich isotherm model, for the two nanocomposites at the applied temperature range, thus the sorption process regulated with Langmuir model.

Applying Eq. (12) for Temkin modelling, the values of the maximum binding energies, AT were 0.623, 1.730 and 63.806 Lg−1 for P5AACMA/ZnO at 293, 313 and 333 K and 1.08, 0.729 and 266.488 for P5AACAN/ZnO nanocomposite, respectively at the same temperatures. Thus, The difference between binding in 60Co(II) to P5AACMA/ZnO and P5AACAN/ZnO nanocomposite owing to the strong electron-withdrawing effect of the nitrile groups lowered the relative reactivity of P5AACAN/ZnO [45].

Thermodynamic study

Applying Eqs. (12–15) in Fig. 12 to calculate the values of ΔG0 for 60Co(II) decreased from − 28.705 kJ mol−1 to − 35.965 kJ on P5AACMA/ZnO nanocomposite and from − 29.445 to − 36.648 kJ mol−1 on P5AACAN/ZnO coupled with a rise temperature from 293 to 333 K (Table 7) The endothermic processes of 60Co(II) sorption were investigated for the both two nanocomposites. The change of entropies (ΔS0) were 181.50 and 180.08 kJ mol−1 K−1 for 60Co(II) sorption on P5AACMA/ZnO and P5AACAN/ZnO nanocomposites, respectively. The positive values of ΔS° suggested that the randomness increased at the P5AACMA/ZnO and P5AACAN/ZnO–60Co(II) metal ion interface. Thus, an increase of the surface affinity of the two nanocomposites toward 60Co(II) were presented.

Desorption studies

The desorbing of 60Co(II) from P5AACMA/ZnO and P5AACAN/ZnO nanocomposites are vital from an economic point of view. Desorption Experiments (Fig. 13) were performed by batch technique using three different desorbing agents 0.1 MHCl, 0.1 M EDTA, and 0.1 M AlCl3.. The order of percentages of Co(II) eluted using the three desorbing agents from P5AACMA/ZnO and P5AACAN/ZnO nanocomposites were 0.1 M EDTA > 0. 1 M HCl > 0.1 M AlCl3. HCl is a strong acid completely ionized to H+ that replaces metal ions adsorbed by ion exchange process [53]. AlCl3 also hydrolyse in water to give HCl and Al(OH)3. Desorption with EDTA solution indicated that an increase in desorption efficiency due to the chelating tendency is higher than ion exchange.

Mechanism of the sorption reaction

A suggested mechanism dominating the polymerization and sorption of 60Co(II) onto the two prepared nanocomposites, Fig. 14. The main functional groups contributing in the sorption reaction. It can be noted that the sorption of 60Co(II) onto P5AACMA/ZnO nanocomposite is more efficient than that onto its counterpart P5AACAN/ZnO nanocomposite. This is due to the amount of adsorption sites of P5AACMA/ZnO nanocomposite is higher than that on the P5AACAN/ZnO nanocomposite. In addition to the strong electron-withdrawing effect of the nitrile groups stabilize negative charge of the carboxylate anion [44] and consequently, lowered the affinity of P5AACAN/ZnO towards 60Co(II). Ion exchange is the main mechanism for the sorption reaction.

Comparative studies

P5AACMA/ZnO and P5AACAN/ZnO nanocomposites sorption capacity is compared with the sorption capacity of other adsorbents [4, 54,55,56,57,58,59,60,61] towards Co(II) and listed in Table 7 P5AACMA/ZnO and P5AACAN/ZnO nanocomposites have reasonable sorption efficiencies and could be used as a host for 60Co(II) radioactive waste.

Conclusion

Nano ZnO was successfully prepared using the bacterial culture Lactobcillus sp. Poly acrylic acid-co-maleic acid /ZnO) nanocomposites or Poly acrylic acid-co-acrylonitrile/ZnO) nanocomposite were synthesized using different concentration of acrylic acid, maleic acid or acrylonitirle monomers and calcinied ZnO nanoparticles via free radical polymerization using gamma irradiation of 60Co at a dose of 25 KGy. The study showed that the optimized nanocomposites P5AACMA/ZnO and P5AACAN/ZnO nanocomposites are efficient sorbents and recommended for the sorption of 60Co(II) the fission product. The sorption reaction was regulated with Langmuir isotherm model and the monolayer adsorption capacities of 60Co(II) onto P5AACMA/ZnO and P5AACAN/ZnO were 18.235, 7.105 mgg−1, respectively at pH 4.5 and 20 °C. The sorption process followed pseudo 2nd order kinetic mechanism. The sorption process was endothermic and spontaneous. Desorption of 60Co(II) from P5AACMA/ZnO and P5AACAN/ZnO nanocomposites were performed using 0.1 M HCl, 0.1 M EDTA and 0.1 M AlCl3. The maximum desorption efficiencies of 60Co(II) from P5AACMA/ZnO and P5AACAN/ZnO were 67.51 and 84.85%, respectively was °Ccurred using 0.1 M EDTA. Thus, P5AACMA/ZnO and P5AACAN/ZnO nanocomposites could be cost efficient alternative to radioactive waste management.

Data availability

All the data used for this work are publicly available.

References

Kundari NA, Permadi M, Megasari K, Nurliati G (2019) Adsorption of Cobalt-60(II) on silica xerogel from rice husk. J Phys Conf Ser 1295:012038

Zhang L, Zhang H, Ge Z, Yu X (2010) Impact of environmental conditions on the sorption behavior of radionuclide 60Co(II) on MnO2. J Radioanal Nucl Chem 288:537–546. https://doi.org/10.1007/s10967-010-0960-3

López-Gonzáleza H, Olguína MT, Bulbulianb S (2019) 60Co-traces sorption in the presence of Fe(III)-59Fe in aqueous solutions by banana husk ash obtained through solution combustion process at different temperatures. Desalination Water Treatment J 164:185–191. https://doi.org/10.5004/dwt.2019.24387

El-Zakla T, Yakout SM, Rizk MA, LasheenYF GHMH (2011) Removal of Cobalt-60 and Caesium-134 Ions from contaminated solutions by sorption using activated carbon. Adsorpt Sci Technol 29:331–344. https://doi.org/10.1260/0263-6174.29.3.331

Karimi S, Tavakkoli Yaraki M, Karri RR (2019) A comprehensive review of the adsorption mechanisms and factors influencing the adsorption process from the perspective of bioethanol dehydration. Renew Sustain Energy Rev 107:535–553. https://doi.org/10.1016/j.rser.2019.03.025

Abu-Dalo MA, Nevostrueva S, Hernandez M (2020) Removal of radionuclides from acidic solution by activated carbon impregnated with methyl- and carboxy-benzotriazoles. Sci Rep 10:11712. https://doi.org/10.1038/s41598-020-68645-4

Norris S (2019) Multiple roles of clays in radioactive waste confinement: introduction. Geol Soc London Spec Publ 482:1–9. https://doi.org/10.1144/sp482-2019-4

Ke X, Bernal SA, Sato T, Provis JL (2019) Alkali aluminosilicate geopolymers as binders to encapsulate strontium-selective titanate ion-exchangers. Dalton Trans 48:12116–12126. https://doi.org/10.1039/c9dt02108f

Sanchez C, Belleville P, Popall M, Nicole L (2011) Applications of advanced hybrid organic–inorganic nanomaterials: from laboratory to market. Chem Soc Rev 40:696. https://doi.org/10.1039/c0cs00136h

Xiang T, Zhou Q, Li K, Li L, Su F, Qian B, Zhao C (2010) Poly(Acrylic acid-co-acrylonitrile) copolymer modified polyethersulfone hollow fiber membrane with pH-sensitivity. Sep Sci Technol 45:2017–2027. https://doi.org/10.1080/01496395.2010.504488

Hossain MA, Roy CK, Sarkar SD, Roy H, Howlader AH, Firoz SH (2020) Improvement of strength of poly(acrylic acid) hydrogels by the incorporation of functionally modified nanocrystalline cellulose. Mater Adv 1:2107–2116. https://doi.org/10.1039/d0ma00478b

Haraguchi K, Takehisa T, Fan S (2002) Effects of clay content on the properties of nanocomposite hydrogels composed of Poly(N-isopropylacrylamide) and clay. Macromolecules 35:10162–10171. https://doi.org/10.1021/ma021301r

Sujan MI, Sarkar SD, Sultana S, Bushra L, Tareq R, Roy CK, Azam MS (2020) Bi-functional silica nanoparticles for simultaneous enhancement of mechanical strength and swelling capacity of hydrogels RSC. Advances 10(2020):6213–6222. https://doi.org/10.1039/C9RA09528D

Liu Z, Yang Z, Luo Y (2012) Swelling, pH sensitivity, and mechanical properties of poly (acrylamide-co-sodium methacrylate) nanocomposite hydrogels impregnated with carboxyl-functionalized carbon nanotubes. Polym Compos 33:665–674. https://doi.org/10.1002/pc.22180

Shin MK, Spinks GM, Shin SR, Kim SI, Kim SJ (2009) Nanocomposite hydrogel with high toughness for bioactuators. Adv Mater 21:1712–1715. https://doi.org/10.1002/adma.200802205

Sarkar SD, Uddin MM, Roy CK, Hossen MJ, Sujan MI, Azam MS (2020) Mechanically tough and highly stretchable poly(acrylic acid) hydrogel cross-linked by 2D graphene oxide. RSC Adv 10:10949–10958. https://doi.org/10.1039/D0RA00678E

Bhatia M, Rajulapati SB, Sonawane S, Girdhar A (2017) Synthesis and implication of novel poly(acrylic acid)/nanosorbent embedded hydrogel composite for lead ion removal. Sci Rep. https://doi.org/10.1038/s41598-017-15642-9

Naseem T, Durrani T (2021) The role of some important metal oxide nanoparticles for wastewater and antibacterial applications: a review. Environ Chem Ecotoxicol 3:59–75. https://doi.org/10.1016/j.enceco.2020.12.001

Dakroury GA, El-Shazly EAA, Hassan HS (2021) Preparation and characterization of ZnO/Chitosan nanocomposite for Cs(I) and Sr(II) sorption from aqueous solutions. J Radioanal Nucl Chem 330:159–174. https://doi.org/10.1007/s10967-021-07935-1

Yadav A, Prasad V, Kathe AA, Raj S, Yadav D, Sundaramoorthy C, Vigneshwaran N (2006) Functional finishing in cotton fabrics using zinc oxide nanoparticle. Bull Mater Sci 29:641–645. https://doi.org/10.1007/s12034-006-0017-y

Jayaseelan C, Abdul Rahuman A, Vishnu Kirthi A, Marimuthu S, Santhoshkumar T, Bagavan A (2012) Novel microbial route to synthesize ZnO nanoparticles using Aeromonas hydrophila and their activity against pathogenic bacteria and fungi. Spectrochim Acta Mol Biomol Spectrosc 90:78–84. https://doi.org/10.1016/j.saa.2012.01.006

Sharma D, Sharma S, Kaith BS, Rajput J, Kaur M (2011) Synthesis of ZnO nanoparticles using surfactant free in-air and microwave method. Appl Surf Sci 257:9661–9672. https://doi.org/10.1016/j.apsusc.2011.06.0

Arena A, Maugeri TL, Pavone B, Iannello D, Gugliandolo C, Bisignano G (2006) Antiviral and immunoregulatory effect of a novel exopolysaccharide from a marine thermotolerant Bacillus licheniformis. Int Immunopharmacol 6:8–13. https://doi.org/10.1016/j.intimp.2005.07.004

Vijayakumar S, Vinoj G, Malaikozhundan B, Shanthi S, Vaseeharan B (2015) Plectranthus amboinicus leaf extract mediated synthesis of zinc oxide nanoparticles and its control of methicillin resistant Staphylococcus aureus biofilm and blood sucking mosquito larvae. Spectrochimica Acta-Part A 137:886–891. https://doi.org/10.1016/j.saa.2014.08.064

El-Arnaouty MB, Abdel Ghaffar AM, El Shafey HM (2007) Radiation-induced graft copolymerization of acrylic acid/acrylonitrile onto LDPE and PET films and its biodegradability. J Appl Polym Sci 107:744–754. https://doi.org/10.1002/app.27099

Jiao AY, Li ZS, Bao LC (2013) Poly (acrylic acid-co-maleic acid) for the enhanced treatment of Cu (II)-loaded aqueous solution and its reuse by ultrafiltration–electrolytic process. Desalination 322:29–36. https://doi.org/10.1016/j.desal.2013.04.028

Fiarman IS, McCallum TF (1995) Pat. 5: 451,644, Assigned to Rohm & Haas Company, Philadelaphia, PA, USA

Kolthoff IM, Kameda T (1931) The hydrolysis of Zinc Sulfate solutions, solubility product of hydrolysis of zinc sulphate solution, solubility product of hydrous zinc oxide and the composition of the latter precipitated from zinc sulphate solution. J Am Chem Soc 53:832–842. https://doi.org/10.1021/ja01354a003

Talam S, Karumuri SR, Gunnam N (2012) Synthesis, characterization, and spectroscopic properties of ZnO nanoparticles. ISRN Nanotechnol 2012:1–6. https://doi.org/10.5402/2012/372505

Hassan HS, Attia LA, Dakroury GA (2020) Exploration of the parameters affecting the radioactive europium removal from aqueous solutions by activated carbon-epoxy composite. Appl Radiat Isot 164:109278. https://doi.org/10.1016/j.apradiso.2020.109278

Lagergren S (1898) About the theory of so-called adsorption of soluble substance. Kungliga Svenska Vetenskaps-Akademiens Handlingar 24:1–39

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465. https://doi.org/10.1016/S0032-9592(98)00112-5

Cheung CW, Porter JF, Mckay G (2000) Sorption kinetics for the removal of copper and zinc from effluents using bone char. Sep Purif Technol 19:55–64

Teng H, Hsieh CT (1999) Activation energy for oxygen chemisorption on carbon at low temperatures. Ind Eng Chem Res 38:292–297

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403. https://doi.org/10.1021/ja02242a004

El-Shazly EAA, Dakroury GA, Someda HH (2021) Sorption of 134Cs radionuclide onto insoluble ferrocyanide loaded silica-gel. J Radioanal Nucl Chem 329:437–449. https://doi.org/10.1007/s10967-021-07789-7

Dakroury GA, Abo-Zahra SF, Hassan HS (2020) Utilization of olive pomace in nano MgO modification for sorption of Ni(II) and Cu(II) metal ions from aqueous solutions. Arab J Chem. https://doi.org/10.1016/j.arabjc.2020.06.008

Lima EC, Hosseini-Bandegharaei A, Moreno-Piraján JC, Anastopoulos I (2018) A critical review of the estimation of the thermodynamic parameters on adsorption equilibria: wrong use of equilibrium constant in the Van’t Hoof equation for calculation of thermodynamic parameters of adsorption. J Mol Liq. https://doi.org/10.1016/j.molliq.2018.10.048

Selvarajan E, Mohanasrinivasan V (2013) Biosynthesis and characterization of ZnO nanoparticles using Lactobacillus plantarum VITES07. Mater Lett. https://doi.org/10.1016/j.matlet.2013.09.020

Liu H, Yu M, Ma H, Wang Z, Li L, Li J (2014) Pre-irradiation induced emulsion co-graft polymerization of acrylonitrile and acrylic acid onto a polyethylene nonwoven fabric. Radiat Phys Chem 94:129–132. https://doi.org/10.1016/j.radphyschem.2013.06.023

Ismar E, Sarac AS (2016) Synthesis and characterization of poly (acrylonitrile-co-acrylic acid) as precursor of carbon nanofibers. Polym Adv Technol 27:1383–1388. https://doi.org/10.1002/pat.3807

Cao D, Gong S, Shu X, Zhu D, Liang S (2019) Preparation of ZnO nanoparticles with high dispersibility based on oriented attachment (OA) process. Nanoscale Res Lett. https://doi.org/10.1186/s11671-019-3038-3

Shaba EY, Jacob JO, Tijani JO, Suleiman MAT (2021) A critical review of synthesis parameters affecting the properties of zinc oxide nanoparticle and its application in wastewater treatment. Appl Water Sci. https://doi.org/10.1007/s13201-021-01370-z

Nasrullah S, Touseef R, Muhammad BA, Rabia T (2018) Fabrication of biocompatible nanocomposite consisted of zinc oxide nanoparticles based poly (Acrylonitrile-co-Acrylic acid). Adv Mater Proc 3:425–431. https://doi.org/10.5185/amp.2018/420

Zhao C, Dolmans L, Zhu XX (2019) Thermoresponsive behavior of Poly(acrylic acid-co-acrylonitrile) with a UCST. Macromolecules 52:4441–4446. https://doi.org/10.1021/acs.macromol.9b00794

Joshi AC, Rufus AL, Velmurugan S (2018) Poly (acrylic acid- co -maleic acid), a polymer dispersant for the control of oxide deposition over nuclear steam generator surfaces. J Nucl Mater 498:421–429. https://doi.org/10.1016/j.jnucmat.2017.11.031

Puigdomenech I (2013), Make equilibrium diagrams using sophisticated algorithms (MEDUSA). Inorganic Chemistry. Royal Institute of Technology, Stockholm Sweden. http://www.kemi.kth.se/medusa. https://sites.google.com/site/chemdiagr/

Dakroury GA, Ali SM, Hassan HS (2021) Assessment of adsorption performance of chitosan/ZrO2 biosorbent composite towards Cs(I) and Co(II) metal ions from aqueous solution. J Polym Res 28:385. https://doi.org/10.1007/s10965-021-02753-1

Akpomie KG, Dawodu FA, Adebowale KO (2015) Mechanism on the sorption of heavy metals from binary-solution by a low cost montmorillonite and its desorption potential. Alex Eng J 54:757–767. https://doi.org/10.1016/j.aej.2015.03.025ISSN1110-0168

Ouyang D, Zhuo Y, Hu I, Zeng Q, Hu Y, He Z (2019) Research on the adsorption behavior of heavy metal ions by porous material prepared with silicate tailings. Minerals 9:291. https://doi.org/10.3390/min9050291

Yapar S, Ozbudak V, DiasLopes AA (2005) Effect of adsorbent concentration to the adsorption of phenol on hexadecyl trimethyl ammonium-bentonite. J Hazard Mater 121:135–139. https://doi.org/10.1016/j.jhazmat.2005.01.02

Kuang Y, Zhang X, Zhou S (2020) Adsorption of methylene blue in water onto activated carbon by surfactant modification. Water 12:587. https://doi.org/10.3390/w12020587

Mujiyanti DR, Irawati U, Akhir NM (2021) Co(II) desorption from silica gel and mercapto-silica hybrid. Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899x/980/1/012018

Rizk HE, Attallah MF, Ali AMI (2017) Investigations on sorption performance of some radionuclides, heavy metals and lanthanides using mesoporous adsorbent material. J Radioanal Nucl Chem 314:2475–2487. https://doi.org/10.1007/s10967-017-5620-4

Dakroury GA, Abo-Zahra SF, Hassan HS, Ali HEA (2020) Improvement of the sorption behavior of aluminum silicate composite toward 134Cs and 60Co radionuclides by non-living biomass of Chlorella vulgaris. Environ Sci Pollut Res Int 27:21109–21125. https://doi.org/10.1007/s11356-020-08260-y

El-Shazly EAA, Dakroury GA, Someda H (2021) Kinetic and isotherm studies for the sorption of 134Cs and 60Co radionuclides onto supported titanium oxide. J Radioanal Nucl Chem 330:127–139. https://doi.org/10.1007/s10967-021-07956-w

Metwally SS, El-Gammal B, Aly HF, Abo-El-Enein SA (2011) Removal and separation of some radionuclides by poly-acrylamide based Ce(IV) phosphate from radioactive waste solutions. Sep Sci Technol 46:1808–1821. https://doi.org/10.1080/01496395.2011.572328

Abbas M, Kaddour S, Trari M (2014) Kinetic and equilibrium studies of cobalt adsorption on apricot stone activated carbon. J Ind Eng Chem 20:745–775. https://doi.org/10.1016/j.jiec.2013.06.030

Attallah MF, Borai EH, Hilal MA, Shehata FA, Abo-Aly MM (2011) Utilization of different crown ethers impregnated polymeric resin for treatment of low level liquid radioactive waste by column chromatography. J Hazard Mater 195:73–81. https://doi.org/10.1016/j.jhazmat.2011.08.007

Ivanets AI, Shashkova IL, Kitikova NV, Drozdova NV (2014) Extraction of Co(II) ions from aqueous solutions with thermally activated dolomite. Russ J Appl Chem 87(3):270–275. https://doi.org/10.1134/s1070427214030045

Ivanets AI, Kitikova NV, Shashkova IL, Roshchina MY, Srivastava V, Sillanpää M (2019) Adsorption performance of hydroxyapatite with different crystalline and porous structure towards metal ions in multicomponent solution. J Water Process Eng 32:100963. https://doi.org/10.1016/j.jwpe.2019.100963

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

The authors confirm that the manuscript has been read and approved by all authors. The authors declare that this manuscript has not been published and not under consideration for publication elsewhere.

Consent to participate

All of the authors consented to participate in the drafting of this manuscript.

Consent for publication

All of the authors consent to publish this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mekawy, Z.A., Moussa, S.I., Mousa, A.M. et al. Sorption of 60Co(II) from aqueous solutions onto biosynthesized zinc oxide nanocomposites. J Radioanal Nucl Chem 331, 2331–2347 (2022). https://doi.org/10.1007/s10967-022-08292-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08292-3