Abstract

There has been an apparent significant increase in the application of composite materials in diverse industrial sectors lately with a focus on improving performance properties and processing techniques. Among several advances noticed, the most significant one for composite industry has been the reinforcement of environment friendly natural fiber (NF) to the polymeric matrix for the fabrication of superior composites. This benign entry of NF in the composite industry has prominently decreased the carbon footprint and composite cost compared to the previously synthetic fiber reinforced ones. Motivated by the decreased cost and latent positive environmental effects, various engineering sectors have already started using these composite materials extensively. The scientific community has observed that hybridization of natural fibers with certain fillers helps to enhance the performance of these composites further. In line with this, the review aims to describe the developments related to the particulate hybridization with short industrially pertinent NF reinforced polypropylene (PP) composites. The effect of hybridization on the composite processability, interfacial interactions, mechanical properties, thermomechanical and thermal properties, and moisture absorption has been covered. The review also covers various challenges and prospects of NF/PP composites for application in the automotive, aerospace and other industries.

Similar content being viewed by others

Data Availability

The data and articles that support the review of this study are available from the corresponding author upon reasonable request.

Abbreviations

- NF:

-

Natural fibers

- FA:

-

Fly ash

- SSL:

-

Sisal fiber

- NFC:

-

Natural fiber reinforced polymeric composite

- PNFC:

-

Particulate hybridized natural fiber reinforced polymeric composite

- SiC:

-

Silicon Carbide

- Al2O3 :

-

Aluminium oxide

- SiO2 :

-

Silicon dioxide

- NaOH:

-

Sodium hydroxide

- TiO2 :

-

Titanium oxide

- KNF:

-

Kenaf fiber

- -OH:

-

Hydroxyl group

- -g-MA:

-

Grafted maleic anhydride

- SEBS:

-

Styrene ethylene butylene styrene

- SBS :

-

Styrene butadiene styrene

- EPR:

-

Ethylene propylene rubber

- EPDM:

-

Ethylene propylene diene monomer

- POE:

-

Polyolefin elastomer

References

Mahmud S, Hasan KMF, Jahid MA et al (2021) Comprehensive review on plant fiber-reinforced polymeric biocomposites. J Mater Sci 56:7231–7264. https://doi.org/10.1007/s10853-021-05774-9

Hasan KMF, Horváth PG, Alpár T (2020) Potential natural fiber polymeric nanobiocomposites: a review. Polym 12:1072. https://doi.org/10.3390/POLYM12051072

Jeyapragash R, Srinivasan V, Sathiyamurthy S (2020) Mechanical properties of natural fiber/particulate reinforced epoxy composites – A review of the literature. Mater Today Proc 22:1223–1227. https://doi.org/10.1016/J.MATPR.2019.12.146

Zaini E, Azaman M, Jamali M, Ismail K (2018) Synthesis and characterization of natural fiber reinforced polymer composites as core for honeycomb core structure: a review. 22:525–550. https://doi.org/10.1177/1099636218758589

Pradeep SA, Iyer RK, Kazan H, Pilla S (2017) Automotive applications of plastics: past, present, and future. In: Kutz M (ed) Applied Plastics Engineering Handbook. Elsevier, Second, pp 651–673

Mohammed L, Ansari MN, Pua G, Jawaid M, Islam MS (2015) A review on natural fiber reinforced polymer composite and its application. 15

Naveen J, Jawaid M, Amuthakkannan P, Chandrasekar M (2018) Mechanical and physical properties of sisal and hybrid sisal fiber-reinforced polymer composites. In: Jawaid M, Thariq M, Saba N (eds) Mechanical and physical testing of biocomposites, fibre-reinforced composites and hybrid composites. Elsevier, pp 427–440

Nurazzi NM, Asyraf MRM, Khalina A et al (2021) A review on natural fiber reinforced polymer composite for bullet proof and ballistic applications. Polym 13:646. https://doi.org/10.3390/POLYM13040646

Piqué R, Romero S, Palomo A et al (2018) The production and use of cordage at the early Neolithic site of La Draga (Banyoles, Spain). Quat Int 468:262–270. https://doi.org/10.1016/J.QUAINT.2016.05.024

Goddard JJ, Kallis G, Norgaard RB (2019) Keeping multiple antennae up: Coevolutionary foundations for methodological pluralism. Ecol Econ 165:106420. https://doi.org/10.1016/J.ECOLECON.2019.106420

Mehmandost N, Soriano ML, Lucena R et al (2019) Recycled polystyrene-cotton composites, giving a second life to plastic residues for environmental remediation. J Environ Chem Eng 7:103424. https://doi.org/10.1016/J.JECE.2019.103424

Maurya AK, Gogoi R, Manik G (2021) Sisal fiber/fly ash reinforced hybrid polypropylene composite: An investigation into the thermal, rheological and crystallographic properties. In: Manik G, Kalia S, Sahoo SK et al (eds) 2nd International Congress on Advances in Mechanical and System Engineering (CAMSE 2021). Springer Singapore, Jalandhar, India

Mansor MR, Nurfaizey AH, Tamaldin N, Nordin MNA (2019) Natural fiber polymer composites: Utilization in aerospace engineering. In: Biomass, Biopolymer-Based Materials, and Bioenergy: Construction, Biomedical, and other Industrial Applications. Woodhead Publishing, pp 203–224

Gholampour A, Ozbakkaloglu T (2019) A review of natural fiber composites: properties, modification and processing techniques, characterization, applications. J Mater Sci 553(55):829–892. https://doi.org/10.1007/S10853-019-03990-Y

Ashok RB, Srinivasa CV, Basavaraju B (2019) Dynamic mechanical properties of natural fiber composites—a review. Adv Compos Hybrid Mater 24(2):586–607. https://doi.org/10.1007/S42114-019-00121-8

Fiore V, Scalici T, Valenza A (2014) Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr Polym 106:77–83. https://doi.org/10.1016/J.CARBPOL.2014.02.016

Komuraiah A, Kumar NS, Prasad BD (2017) The study of relationship between fracture angles of natural fiber with its micro fibril angle. Procedia Eng 173:1198–1202. https://doi.org/10.1016/J.PROENG.2016.12.117

Lotfi A, Li H, Dao DV, Prusty G (2019) Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. 34:238–284. https://doi.org/10.1177/0892705719844546

Yan L, Kasal B, Huang L (2016) A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos Part B Eng 92:94–132. https://doi.org/10.1016/J.COMPOSITESB.2016.02.002

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596. https://doi.org/10.1016/J.PROGPOLYMSCI.2012.04.003

Ramesh M, Palanikumar K, Reddy KH (2017) Plant fibre based bio-composites: Sustainable and renewable green materials. Renew Sustain Energy Rev 79:558–584. https://doi.org/10.1016/J.RSER.2017.05.094

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibres, biodegradable polymers and biocomposites: an overview. Macromol Mater Eng 277:1–24. https://doi.org/10.1002/(SICI)1439-2054(20000301)276:1

Polypropylene in the Automotive Industry - Extruders of plastic sheet and film. http://www.euroextrusions.com/polypropylene-automotive-industry/. Accessed 27 Sept 2018

Patil A, Patel A, Purohit R (2017) An overview of Polymeric Materials for Automotive Applications. In: Materials Today: Proceedings. Elsevier, pp 3807–3815

Markarian J (2007) Long fibre reinforced thermoplastics continue growth in automotive. Plast Addit Compd 9:20–24. https://doi.org/10.1016/S1464-391X(07)70025-9

Jansz J (1999) Polypropylene in automotive applications. 643–651. https://doi.org/10.1007/978-94-011-4421-6_87

Kausar A (2017) Polyurethane composite foams in high-performance applications: a review. 57:346–369. https://doi.org/10.1080/03602559.2017.1329433

Akindoyo JO, Beg MDH, Ghazali S et al (2016) Polyurethane types, synthesis and applications – a review. RSC Adv 6:114453–114482. https://doi.org/10.1039/C6RA14525F

Hanafi M, Sah M, Mohd A et al (2017) Mechanical properties of coconut shell powder reinforced PVC composites in automotive applications. J Mech Eng 14:49–61

McKeen LW (2010) Styrenic Plastics. In: McKeen LW (ed) Fatigue and tribological properties of plastics and elastomers. Elsevier Inc., Second Edi, pp 51–71

Pious CV, Thomas S (2016) Polymeric materials—structure, properties, and applications. Print Polym Fundam Appl. https://doi.org/10.1016/B978-0-323-37468-2.00002-6

Acrylonitrile-butadiene-styrene (ABS) Uses and Market Data | ICIS. https://www.icis.com/explore/resources/news/2007/10/18/9071051/acrylonitrile-butadiene-styrene-abs-uses-and-market-data/. Accessed 2 Aug 2021

Seubert C, Nietering K, Nichols M et al (2012) An overview of the scratch resistance of automotive coatings: exterior clearcoats and polycarbonate hardcoats. Coatings 2:221–234. https://doi.org/10.3390/COATINGS2040221

Anthony BT (1985) Lexan polycarbonate for automotive forward lighting. Mater Des 6:293–302. https://doi.org/10.1016/0261-3069(85)90011-1

Birch A, Dal Castel C, Kiziltas A, Mielewski D, Simon L. Development of cost effective and sustainable polyamide blends for automotive applications. In SPE Automotive Composites Conference & Exhibition 2015 (pp. 1-10)

Shinde NG, Dilip D, Patel M A short review on automobile dashboard materials. https://doi.org/10.1088/1757-899X/810/1/012033

Begum SA, Rane AV, Kanny K (2020) Applications of compatibilized polymer blends in automobile industry. Compat Polym Blends Micro Nano Scale Phase Morphol Interphase Charact Prop. https://doi.org/10.1016/B978-0-12-816006-0.00020-7

Chirayil CJ, Joy J, Maria HJ et al (2016) Polyolefins in automotive industry. 265–283. https://doi.org/10.1007/978-3-319-25982-6_11

Atakan R, Sezer S, Karakas H (2018) Development of nonwoven automotive carpets made of recycled PET fibers with improved abrasion resistance. J Ind Text 49:835–857. https://doi.org/10.1177/1528083718798637

Sales JCS, de Castro AM, Ribeiro BD, Coelho MAZ (2022) Post-Consumer Poly(ethylene terephthalate) (PET) Depolymerization by Yarrowia lipolytica: A Comparison between Hydrolysis Using Cell-Free Enzymatic Extracts and Microbial Submerged Cultivation. Molecules 27(21):7502. https://doi.org/10.3390/molecules27217502

Maurya AK, Gogoi R, Manik G (2021) Study of the moisture mitigation and toughening effect of fly-ash particles on sisal fiber-reinforced hybrid polypropylene composites. J Polym Environ 297(29):2321–2336. https://doi.org/10.1007/S10924-021-02043-3

Maurya AK, Gogoi R, Manik G (2021) Mechano-chemically activated fly-ash and sisal fiber reinforced PP hybrid composite with enhanced mechanical properties. Cellulose. https://doi.org/10.1007/s10570-021-03995-4

Koohestani B, Darban AK, Mokhtari P et al (2019) Comparison of different natural fiber treatments: a literature review. Int J Environ Sci Technol 16:629–642. https://doi.org/10.1007/s13762-018-1890-9

Pickering KL, Efendy MGA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos Part A Appl Sci Manuf 83:98–112. https://doi.org/10.1016/J.COMPOSITESA.2015.08.038

Biagiotti J, Puglia D, Kenny JM (2008) A review on natural fibre-based composites-part I. 1:37–68. https://doi.org/10.1300/J395V01N02_04

Koohestani B (2017) Effect of saline admixtures on mechanical and microstructural properties of cementitious matrices containing tailings. Constr Build Mater 156:1019–1027. https://doi.org/10.1016/J.CONBUILDMAT.2017.09.048

Kabir MM, Wang H, Lau KT, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos Part B Eng 43:2883–2892. https://doi.org/10.1016/J.COMPOSITESB.2012.04.053

El-Abbassi FE, Assarar M, Ayad R, Lamdouar N (2015) Effect of alkali treatment on Alfa fibre as reinforcement for polypropylene based eco-composites: Mechanical behaviour and water ageing. Compos Struct 133:451–457. https://doi.org/10.1016/J.COMPSTRUCT.2015.07.112

Homan W, Heron AJ (2004) Wood modification developments. Heron 49

Väisänen T, Haapala A, Lappalainen R, Tomppo L (2016) Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: a review. Waste Manag 54:62–73. https://doi.org/10.1016/J.WASMAN.2016.04.037

Lu JZ, Professor A, McNabb HS, Professor J (2000) Chemical coupling in wood fiber and polymer composites: a review of coupling agents and treatments. Wood Fiber Sci 88–104

George J, Sreekala MS, Thomas S (2001) A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym Eng Sci 41:1471–1485. https://doi.org/10.1002/PEN.10846

Gogoi R, Kumar N, Mireja S et al (2019) Effect of hollow glass microspheres on the morphology, rheology and crystallinity of short bamboo fiber-reinforced hybrid polypropylene composite. JOM 71:548–558. https://doi.org/10.1007/s11837-018-3268-3

Kumar J, Maurya AK, Gupta HS et al (2022) Development of eco-friendly bio-composite by reinforcing pineapple fruit waste crown fiber to ethylene-propylene rubber modified polyethylene. Polym Compos 43:8259–8273. https://doi.org/10.1002/PC.26997

Mihalic M, Sobczak L, Pretschuh C, Unterweger C (2019) Increasing the impact toughness of cellulose fiber reinforced polypropylene composites—influence of different impact modifiers and production scales. J Compos Sci 3:82. https://doi.org/10.3390/JCS3030082

Sain M, Suhara P, Law S, Bouilloux A (2005) Interface modification and mechanical properties of natural fiber-polyolefin composite products. J Reinf Plast Compos 24:121–130. https://doi.org/10.1177/0731684405041717

Sarikaya E, Çallioğlu H, Demirel H (2019) Production of epoxy composites reinforced by different natural fibers and their mechanical properties. Compos Part B Eng 167:461–466. https://doi.org/10.1016/J.COMPOSITESB.2019.03.020

Panaitescu DM, Vuluga Z, Sanporean CG et al (2019) High flow polypropylene/SEBS composites reinforced with differently treated hemp fibers for injection molded parts. Compos Part B Eng 174:107062. https://doi.org/10.1016/J.COMPOSITESB.2019.107062

Mochane M, Mokhena T, Mokhothu T et al (2019) Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym Lett 13:159–198. https://doi.org/10.3144/expresspolymlett.2019.15

Asumani OML, Reid RG, Paskaramoorthy R (2012) The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos Part A Appl Sci Manuf 43:1431–1440. https://doi.org/10.1016/J.COMPOSITESA.2012.04.007

Puch F, Hopmann C (2015) Experimental investigation of the influence of the compounding process and the composite composition on the mechanical properties of a short flax fiber–reinforced polypropylene composite. Polym Compos 36:2282–2290. https://doi.org/10.1002/PC.23141

Sullins T, Pillay S, Komus A, Ning H (2017) Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos Part B Eng 114:15–22. https://doi.org/10.1016/J.COMPOSITESB.2017.02.001

Feng Y, Hu Y, Zhao G et al (2011) Preparation and mechanical properties of high-performance short ramie fiber-reinforced polypropylene composites. J Appl Polym Sci 122:1564–1571. https://doi.org/10.1002/APP.34281

Rana AK, Mandal A, Bandyopadhyay S (2003) Short jute fiber reinforced polypropylene composites: effect of compatibiliser, impact modifier and fiber loading. Compos Sci Technol 63:801–806. https://doi.org/10.1016/S0266-3538(02)00267-1

Sanjay MR, Arpitha GR, Yogesha B (2015) Study on mechanical properties of natural - glass fibre reinforced polymer hybrid composites: a review. Mater Today Proc 2:2959–2967. https://doi.org/10.1016/J.MATPR.2015.07.264

Pradeep SA, Iyer RK, Kazan H, Pilla S (2017) automotive applications of plastics: past, present, and future. Appl Plast Eng Handb Process Mater Appl Second Ed. https://doi.org/10.1016/B978-0-323-39040-8.00031-6

Fawaz J, Vikas M (2014) In: Mittal V (ed) Polymer nanotube nanocomposites: a review of synthesis methods, properties and applications. Polymer Nanotubes Nanocomposites: Synthesis, Properties and Applications, p 1–44

Zhao D, Zhou Z (2014) Applications of lightweight composites in automotive industries.https://doi.org/10.1021/bk-2014-1175.ch009

Joshi SV, Drzal LT, Mohanty AK, Arora S (2004) Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos Part A Appl Sci Manuf 35:371–376. https://doi.org/10.1016/J.COMPOSITESA.2003.09.016

Adesina OT, Jamiru T, Sadiku ER, Ogunbiyi OF, Beneke LW (2019) Mechanical evaluation of hybrid natural fibre–reinforced polymeric composites for automotive bumper beam: a review. Int J Adv Manuf Technol. 103(5):1781–1797

Boland CS, De KR, Keoleian GA et al (2016) Life cycle impacts of natural fiber composites for automotive applications: effects of renewable energy content and lightweighting. J Ind Ecol 20:179–189. https://doi.org/10.1111/JIEC.12286

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers, and biocomposites. CRC Press

Yahaya R, Sapuan SM, Jawaid M et al (2016) (2016) Investigating ballistic impact properties of woven kenaf-aramid hybrid composites. Fibers Polym 172(17):275–281. https://doi.org/10.1007/S12221-016-5678-6

da Luz FS, Garcia Filho FDC, Oliveira MS et al (2020) Composites with natural fibers and conventional materials applied in a hard armor: a comparison. Polym 12:1920. https://doi.org/10.3390/POLYM12091920

Yahaya R, Sapuan SM, Jawaid M et al (2014) Quasi-static penetration and ballistic properties of kenaf–aramid hybrid composites. Mater Des 63:775–782. https://doi.org/10.1016/J.MATDES.2014.07.010

Anidha S, Latha N, Muthukkumar M (2020) Effect of polyaramid reinforced with sisal epoxy composites: Tensile, impact, flexural and morphological properties. J Mater Res Technol 9:7947–7954. https://doi.org/10.1016/J.JMRT.2020.04.081

Jambari S, Yahya Y, Abdullah MR, Jawaid M (2017) Woven Kenaf/Kevlar Hybrid Yarn as potential fiber reinforced for anti-ballistic composite material. Fibers Polym 18:563–568. https://doi.org/10.1007/s12221-017-6950-0

Salman SD, Leman Z, Sultan MT, Ishak MR, Cardona F (2016) Ballistic impact resistance of plain woven kenaf/aramid reinforced polyvinyl butyral laminated hybrid composite. BioResources 11(3):7282–7295

Elseify LA, Midani M, El-Badawy A, Jawaid M (2021) Manufacturing automotive components from sustainable natural fiber composites. Springer International Publishing, Cham

Boegler O, Kling U, Empl D, Isikveren AT (2015) Potential of sustainable materials in wing structural design (pp. 16-18). Bonn, Germany: Deutsche Gesellschaft für Luft-und Raumfahrt-Lilienthal-Oberth eV.

Kling U, Empl D, Boegler O, Isikveren AT (2015) Future aircraft wing structures using renewable materials. Proc Dtsch Luft- und Raumfahrtkongress 8785:370118

Black S (2015) Looking to lighten up aircraft interiors? Try natural fibers! | CompositesWorld

De F, Eloy S, Rony R et al (2015) Comparison between mechanical properties of bio and synthetic composites for use in aircraft interior structures. In: Meeting on Aeronautical Composite Materials and Structures – MACMS 2015

Bhatnagar A, Sain M (2016) Processing of cellulose nanofiber-reinforced composites. 24:1259–1268. https://doi.org/10.1177/0731684405049864

Walsh J, Kim HI, Suhr J (2017) Low velocity impact resistance and energy absorption of environmentally friendly expanded cork core-carbon fiber sandwich composites. Compos Part A Appl Sci Manuf 101:290–296. https://doi.org/10.1016/J.COMPOSITESA.2017.05.026

Manan NH, Majid DL, Romli FI (2016) Mould design and manufacturing considerations of honeycomb biocomposites with transverse fibre direction for aerospace application. IOP Conf Ser Mater Sci Eng 152:012013. https://doi.org/10.1088/1757-899X/152/1/012013

Chok EYL, Majid DLAA, Harmin MY (2017) Effect of low velocity impact damage on the natural frequency of composite plates. In: IOP Conference Series: Materials Science and Engineering. IOP Publishing, p 012025

Haris MY, Laila D, Zainudin ES et al (2011) Preliminary review of biocomposites materials for aircraft radome application. Key Eng Mater 471–472:563–567. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/KEM.471-472.563

Ghori SW, Siakeng R, Rasheed M et al (2018) The role of advanced polymer materials in aerospace. In: Sustainable Composites for Aerospace Applications. Woodhead Publishing, pp 19–34

Muhammad A, Rahman MR, Baini R, Bin Bakri MK (2021) Applications of sustainable polymer composites in automobile and aerospace industry. In: Advances in Sustainable Polymer Composites. LTD, pp 185–207

Rowell RM (2008) Natural fibres: types and properties. In: Properties and Performance of Natural-Fibre Composites. Woodhead Publishing, pp 3–66

Haameem M, Abdul Majid MS, Afendi M et al (2016) Effects of water absorption on Napier grass fibre/polyester composites. Compos Struct 144:138–146. https://doi.org/10.1016/J.COMPSTRUCT.2016.02.067

Dhakal HN, Zhang ZY, Richardson MOW (2007) Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos Sci Technol 67:1674–1683. https://doi.org/10.1016/J.COMPSCITECH.2006.06.019

Mokhothu TH, John MJ (2017) Bio-based coatings for reducing water sorption in natural fibre reinforced composites. Sci Rep 71(7):1–8. https://doi.org/10.1038/s41598-017-13859-2

Munirah Abdullah N, Ahmad I (2012) Effect of chemical treatment on mechanical and water-sorption properties coconut fiber-unsaturated polyester from recycled PET. ISRN Mater Sci 2012:1–8. https://doi.org/10.5402/2012/134683

Wu J, Yu D, Chan C-M et al (2000) Effect of fiber pretreatment condition on the interfacial strength and mechanical properties of wood Fiber/PP composites. Appl Polym Sci 76:1000–1010. https://doi.org/10.1002/(SICI)1097-4628(20000516)76:7

Agrawal R, Saxena NS, Sharma KB et al (2000) Activation energy and crystallization kinetics of untreated and treated oil palm fibre reinforced phenol formaldehyde composites. Mater Sci Eng A 277:77–82. https://doi.org/10.1016/S0921-5093(99)00556-0

Wu Y, Xia C, Cai L et al (2018) Water-resistant hemp fiber-reinforced composites: In-situ surface protection by polyethylene film. Ind Crops Prod 112:210–216. https://doi.org/10.1016/J.INDCROP.2017.12.014

Mrad H, Alix S, Migneault S et al (2018) Numerical and experimental assessment of water absorption of wood-polymer composites. Measurement 115:197–203. https://doi.org/10.1016/J.MEASUREMENT.2017.10.011

Panthapulakkal S, Sain M (2016) Studies on the water absorption properties of short hemp—glass fiber hybrid polypropylene composites. 41:1871–1883. https://doi.org/10.1177/0021998307069900

Akil HM, Cheng LW, Mohd Ishak ZA et al (2009) Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos Sci Technol 69:1942–1948. https://doi.org/10.1016/J.COMPSCITECH.2009.04.014

Alamri H, Low IM (2012) Effect of water absorption on the mechanical properties of n-SiC filled recycled cellulose fibre reinforced epoxy eco-nanocomposites. Polym Test 31:810–818. https://doi.org/10.1016/J.POLYMERTESTING.2012.06.001

Selmi A (2014) Void effect on carbon fiber epoxy composites. In 2nd International conference on emerging trends in engineering and technology, ICETET2014 (pp 179-183)

Mehdikhani M, Gorbatikh L, Verpoest I, Lomov SV (2018) Voids in fiber-reinforced polymer composites: a review on their formation, characteristics, and effects on mechanical performance. 53:1579–1669. https://doi.org/10.1177/0021998318772152

Ismail A, Jawaid M, Naveen J (2019) Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites. Materials. https://doi.org/10.3390/ma12132094

Calabrese L, Fiore V, Scalici T, Valenza A (2018) Experimental assessment of the improved properties during aging of flax/glass hybrid composite laminates for marine applications. J Appl Polym Sci. https://doi.org/10.1002/app.47203

Ramlee NA, Jawaid M, Zainudin ES, Yamani SAK (2019) Tensile, physical and morphological properties of oil palm empty fruit bunch/sugarcane bagasse fibre reinforced phenolic hybrid composites. J Mater Res Technol 8:3466–3474. https://doi.org/10.1016/J.JMRT.2019.06.016

Bucknall CB (1977) Impact strength. Toughened Plast 272–304.https://doi.org/10.1007/978-94-017-5349-4_10

Sain M, Suhara P, Law S, Bouilloux A (2016) Interface modification and mechanical properties of natural fiber-polyolefin composite products. J Reinf Plast Compos 24:121–130. https://doi.org/10.1177/0731684405041717

Dubnikova IL, Berezina SM, Antonov AV (2004) Effect of rigid particle size on the toughness of filled polypropylene. J Appl Polym Sci 94:1917–1926. https://doi.org/10.1002/APP.21017

Malkapuram R, Kumar V, Negi YS (2008) Recent development in natural fiber reinforced polypropylene composites. 28:1169–1189. https://doi.org/10.1177/0731684407087759

Ruksakulpiwat Y, Suppakarn N, Sutapun W, Thomthong W (2007) Vetiver–polypropylene composites: physical and mechanical properties. Compos Part A Appl Sci Manuf 38:590–601. https://doi.org/10.1016/J.COMPOSITESA.2006.02.006

Zinge C, Kandasubramanian B (2020) Nanocellulose based biodegradable polymers. Eur Polym J 133:109758. https://doi.org/10.1016/J.EURPOLYMJ.2020.109758

Tessema A, Zhao D, Moll J et al (2017) Effect of filler loading, geometry, dispersion and temperature on thermal conductivity of polymer nanocomposites. Polym Test 57:101–106. https://doi.org/10.1016/J.POLYMERTESTING.2016.11.015

Zhang W (2014) Nanoparticle aggregation: principles and modeling. Adv Exp Med Biol 811:19–43. https://doi.org/10.1007/978-94-017-8739-0_2

Nichols G, Byard S, Bloxham MJ et al (2002) A review of the terms agglomerate and aggregate with a recommendation for nomenclature used in powder and particle characterization. J Pharm Sci 91:2103–2109. https://doi.org/10.1002/JPS.10191

Vatansever E, Arslan D, Nofar M (2019) Polylactide cellulose-based nanocomposites. Int J Biol Macromol 137:912–938. https://doi.org/10.1016/J.IJBIOMAC.2019.06.205

Yue L, Maiorana A, Khelifa F et al (2018) Surface-modified cellulose nanocrystals for biobased epoxy nanocomposites. Polymer (Guildf) 134:155–162. https://doi.org/10.1016/J.POLYMER.2017.11.051

Dundu M, Gao X (2014) Construction Materials and Structures: Proceedings of the First International Conference on Construction Materials and Structures

Singh H, Singh T (2019) Effect of fillers of various sizes on mechanical characterization of natural fiber polymer hybrid composites: a review. Mater Today Proc 18:5345–5350. https://doi.org/10.1016/J.MATPR.2019.07.560

Agarwal J, Mohanty S, Nayak SK (2021) Influence of cellulose nanocrystal/sisal fiber on the mechanical, thermal, and morphological performance of polypropylene hybrid composites. Polym Bull 78:1609–1635. https://doi.org/10.1007/S00289-020-03178-4/TABLES/2

Krishnaiah P, Manickam S, Ratnam CT et al (2020) Surface-treated short sisal fibers and halloysite nanotubes for synergistically enhanced performance of polypropylene hybrid composites. https://doi.org/10.1177/0892705720946063

Essabir H, Bensalah MO, Rodrigue D et al (2016) Structural, mechanical and thermal properties of bio-based hybrid composites from waste coir residues: fibers and shell particles. Mech Mater 93:134–144. https://doi.org/10.1016/J.MECHMAT.2015.10.018

Arrakhiz FZ, Benmoussa K, Bouhfid R, Qaiss A (2013) Pine cone fiber/clay hybrid composite: Mechanical and thermal properties. Mater Des 50:376–381. https://doi.org/10.1016/J.MATDES.2013.03.033

Oladele IO, Ibrahim IO, Akinwekomi AD, Talabi SI (2019) Effect of mercerization on the mechanical and thermal response of hybrid bagasse fiber/CaCO3 reinforced polypropylene composites. Polym Test 76:192–198. https://doi.org/10.1016/J.POLYMERTESTING.2019.03.021

Upadhyaya P, Garg M, Kumar V, Nema AK (2012) The effect of water absorption on mechanical properties of wood flour/wheat husk polypropylene hybrid composites. Mater Sci Appl 2012:317–325. https://doi.org/10.4236/MSA.2012.35047

Najafi A, Kord B, Abdi A, Ranaee S (2011) The impact of the nature of nanoclay on physical and mechanical properties of polypropylene/reed flour nanocomposites. 25:717–727. https://doi.org/10.1177/0892705711412813

Mirbagheri J, Tajvidi M, Hermanson JC, Ghasemi I (2007) Tensile properties of wood flour/kenaf fiber polypropylene hybrid composites. J Appl Polym Sci 105:3054–3059. https://doi.org/10.1002/APP.26363

Idumah CI, Hassan A (2016) Characterization and preparation of conductive exfoliated graphene nanoplatelets kenaf fibre hybrid polypropylene composites. Synth Met 212:91–104. https://doi.org/10.1016/J.SYNTHMET.2015.12.011

Mohd HA, Abu Bakar MB, Masri MN et al (2020) Mechanical and thermal properties of hybrid non-woven kenaf fibre mat-graphene nanoplatelets reinforced polypropylene composites. Mater Sci Forum 1010:124–129. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/MSF.1010.124

Lee CH, Sapuan SM, Hassan MR (2017) Mechanical and thermal properties of kenaf fiber reinforced polypropylene/magnesium hydroxide composites. 12:50–58. https://doi.org/10.1177/155892501701200206

Boujmal R, Kakou CA, Nekhlaoui S et al (2017) Alfa fibers/clay hybrid composites based on polypropylene: mechanical, thermal, and structural properties. 31:974–991. https://doi.org/10.1177/0892705717729197

Venkateswara Rao T, Somaiah Chowdary M, Siva Sanakara Babu C, Mohan Sumanth C (2019) Effect of bamboo fiber on mechanical properties of fly ash with polypropylene composites. Lect Notes Mech Eng. https://doi.org/10.1007/978-981-13-1780-4_42

Islam M, Sharif A, Hussain M, Hassan I (2019) Synergic effect of recycled cotton fabric and wood saw dust reinforced biodegradable polypropylene composites. Bangladesh J Sci Ind Res 54:21–30. https://doi.org/10.3329/BJSIR.V54I1.40727

Saba N, Tahir PM, Jawaid M (2014) A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polym 6:2247–2273. https://doi.org/10.3390/POLYM6082247

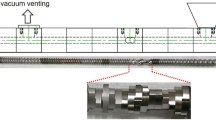

Extruder Processing Zone (EPZ) is the heart of a Co-rotating Twin-Screw Extruder. http://atozplastics.com/upload/literature/Extruder-Processing-Zone-EPZ-Co-rotating-Twin-Screw-Extruder-quality-compounded-material-output.asp. Accessed 7 Mar 2022

Araújo JR, Waldman WR, De Paoli MA (2008) Thermal properties of high density polyethylene composites with natural fibres: coupling agent effect. Polym Degrad Stab 93:1770–1775. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2008.07.021

Essabir H, Raji M, Bouhfid R, Qaiss AEK (2016) Nanoclay and natural fibers based hybrid composites: mechanical morphological, thermal and rheological properties. https://doi.org/10.1007/978-981-10-0950-1_2

Maurya AK, Gogoi R, Sethi SK, Manik G (2021) A combined theoretical and experimental investigation of the valorization of mechanical and thermal properties of the fly ash-reinforced polypropylene hybrid composites. J Mater Sci. https://doi.org/10.1007/S10853-021-06383-2

L Lv L, Ding X, Gu H, Hu G (2015) The effect of SEBS and POE on properties of polypropylene. 2:188–194

Vigneshwaran S, Sundarakannan R, John KM et al (2020) Recent advancement in the natural fiber polymer composites: A comprehensive review. J Clean Prod 277:124109. https://doi.org/10.1016/J.JCLEPRO.2020.124109

Maurya AK, Gogoi R, Manik G (2022) Thermal behavior of elastomer blends and composites. 149–169. https://doi.org/10.1016/B978-0-323-85832-8.00008-0

Veerasimman A, Shanmugam V, Rajendran S et al (2021) Thermal properties of natural fiber sisal based hybrid composites–a brief review. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1870619

Sui G, Fuqua MA, Ulven CA, Zhong WH (2009) A plant fiber reinforced polymer composite prepared by a twin-screw extruder. Bioresour Technol 100:1246–1251. https://doi.org/10.1016/J.BIORTECH.2008.03.065

Maurya AK, Gogoi R, Manik G (2022) Recycling and reinforcement potential for the fly ash and sisal fiber reinforced hybrid polypropylene composite. Polym Compos 43:1060–1077. https://doi.org/10.1002/PC.26434

Acknowledgements

All the authors wish to thank the Indian Institute of Technology, Roorkee for providing excellent research facilities and environment. First author wants to thank the Ministry of Education, Government of India for offering fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no competing interests and funding related to the current work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maurya, A.K., Manik, G. Advances towards development of industrially relevant short natural fiber reinforced and hybridized polypropylene composites for various industrial applications: a review. J Polym Res 30, 47 (2023). https://doi.org/10.1007/s10965-022-03413-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03413-8