Abstract

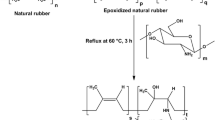

In order to plasticize neoprene rubber (CR), a natural plasticizer,derived from Cashew Nut Shell Liquid (CNSL),was covalently bound to CR at room temperature via click chemistry. That is, the covalent attachment of the cardanol-based internal plasticizer to CR matrix, is descried for the first time. The chemical structure and properties of cardanol-based internal plasticizer and internally plasticized CR materials was characterized by FTIR, dynamic mechanical analysis (DMA), plasticizer migration tests, differential scanning calorimeter (DSC), and gel permeation chromatography (GPC). Results indicated when cardanol was grafted onto CR (CR-CPE), CR-CPE had a lower Tg compared with plain CR. Self-plasticization CR samples showed zero migration in petroleum ether, but 1. 58 mg·mL−1 of cardanol leached from CR/cardanol blend(CR-car) system into petroleum ether. The CR-CPE materials were expected to be commercial application in producing food packing, toys, and medical devices with high requirements in migration resistance.

Similar content being viewed by others

References

Sampson J, Korte D (2011) DEHP-plasticised PVC: relevance to blood services*. Transfus. Med. 21:73–83

Lithner D, Larsson A, Dave G (2011) Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Sci. Total Environ. 409:3309–3324

Hines CJ, Hope NB, Deddens JA, Silva MJ, Calafat AM (2012) Occupational exposure to diisononyl phthalate (DiNP) in polyvinyl chloride processing operations. Int. Arch. Occup. Environ. Health 85:317–325

Chiellini F, Ferri M, Morelli A, Dipaola L, Latini G (2013) Perspectives on alternatives to phthalate plasticized poly(vinyl chloride) in medical devices applications. Prog. Polym. Sci. 38:1067–1088

Chiellini F, Ferri M, Latini G (2011). Int. J. Pharm. 409:7

Li Z, Liu N, Yao Y, Chen S, Wang H, Wang H (2015). RSC Adv. 5:901

Rahman M, Brazel CS (2004). Prog. Polym. Sci. 29:1223

Panda B, Parihar AS, Mallick S (2014). Int. J. Biol. Macromol. 67:295

Niazi MBK, Zijlstra M, Broekhuis AA (2013). Carbohydr. Polym. 97:571

Garg B, Bisht T, Ling YC (2014) Sulfonated graphene as highly efficient and reusable acid carbocatalyst for the synthesis of ester plasticizers. RSC Adv. 4:57297–57307

Yang D, Peng X, Zhong L, Cao X, Chen W, Zhang X (2014). Carbohydr. Polym. 103:198

Fenollar O, García D, Sánchez L, López J, Balart R (2009) Optimization of the curing conditions of PVC plastisols based on the use of an epoxidized fatty acid ester plasticizer. Eur. Polym. J. 45:2674–2684

Salahi A, Mohammadi T, Nikbakht M, Golshenas M, Noshadi I, Desalin (2012). Water Treat 48:27

de Oliveira PC, de Oliveira AM, Garcia A, de Souza Barboza JC, de Carvalho Zavaglia CA, dos Santos AM (2005). Eur. Polym. J. 41:1883

Ribeiro FWM, Kotzebue LRV, Oliveira J’s R, Maia FJN, Mazzetto SE, Lomonaco D (2017). J. Therm. Anal. Calorim. 129:281–289

Ma Y, Hu H, Northwood D, Nie X (2007) Optimization of the electrolytic plasma oxidation processes for corrosion protection of magnesium alloy AM50 using the Taguchi method. J Mater ProcessTechnol 182:58–64

Messori M, Toselli M, Pilati F, Fabbri E, Fabbri P, Pasquali L et al (2004). Polymer 45:805–813

Romero Tendero PM, Jimenez A, Greco A, Maffezzoli A (2006) Viscoelastic and thermal characterization of crosslinked PVC. Eur. Polym. J. 42:961–969

Rosales-Jasso A, Arias G, Rodriguez OS, Allen NS (2000). Polym. Degrad. Stab. 68:253

Yu Q, Zhu S, Zhou W (1998). J. Polym. Sci. A Polym. Chem. 36:851–860

Sunny MC, Ramesh P, George KE (2006). J. Appl. Polym. Sci. 102:4720

Jie C, Liu Z, Nie X et al (2018). J. Polym. Res. 25:128

He Z, Li D, Hensley DK, Rondinone AJ, Chen J (2013) Switching phase separation mode by varying the hydrophobicity of polymer additives in solution-processed semiconducting small-molecule/polymer blends. Appl. Phys. Lett. 103:113301

He Z, Chen J, Li D (2019). Soft Matter 15:5790

Bi S, Li Y, He Z, Ouyang Z, Guo Q, Jiang C (2019) Self-assembly diketopyrrolopyrrole-based materials and polymer blend with enhanced crystal alignment and property for organic field-effect transistors. Org. Electron. 65:96–99

He Z, Zhang Z, Asare-Yeboah K, Bi S (2019). J. Mater. Sci. Mater. Electron. 30(15):14335

Thirukumaran P, Parveen AS, Sarojadevi M (2014). ACS Sustain. Chem. Eng. 2:2790

Bi S, He Z, Li Q, Yan Y, Asare-Yeboah K et al (2019). Phys. Chem. Chem. Phys. 21(5):2450

Momin MA, Hossain KS, Bhuiyan AH (2019). J. Polym. Res. 26(3):83

Rajesh K, Crasta V, Rithin Kumar NB, Shetty G, Rekha PD (2019). J. Polym. Res. 26(4):1

Wang C, Wang TM, Wang QH (2019). J. Polym. Res. 26(1):1

Ayat M, Rahmouni A, Belbachir M, Bensaada N, Baghdadli MC, Meghabar R (2019). J. Polym. Res. 26(9):1

He Z, Zhang Z, Bi S (2019). J. Polym. Res. 26(7):173

Xu GM, Ji YB, Yang Z, Tan H (2012) Influence of Structure and Property of Plasticizers on Viscosity and Aging Process of PVC Plastisols. Appl. Mech. Mater. 161:15–20

Yang P, Yan J, Sun H, Fan H, Chen Y, Wang F, Shi B (2015). RSC Adv. 5:16980

Natarajan M, Murugavel SC (2017). Polym. Bull. 74:3319

Greco A (2010). Polym. Degrad. Stab. 95(11):2169

Mohapatra S, Nando GB (2014). RSC Adv. 4:15406

Zhang W, Jiang N, Zhang T (2019) Self-plasticization of neoprene rubber via click chemistry from environmentally sustainable cardanol. J. Elastom. Plast. https://doi.org/10.1177/0095244319869768,009524431986976

Lakshmi S, Jayakrishnan A (1998). Polymer 39:151

Tendero PMR, Jimenez A, Greco A, Maffezzoli A (2006). Eur. Polym. J. 42(4):961

Funding

The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was financially supported by the Natural Science Foundation of Liaoning Province of China (grant no. 201602597).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration of conflicting interests

The author(s) declared no potential conflicts of interest with respect to the research, authorship,and/or publication of this article.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, W., Zhang, T., Jiang, N. et al. Chemical modification of neoprene rubber by grafting cardanol, a versatile renewable materials from cashew industry. J Polym Res 27, 163 (2020). https://doi.org/10.1007/s10965-020-02122-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02122-4