Abstract

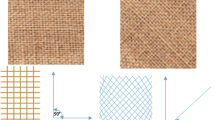

Natural fiber composite laminates are nowadays used in structural application such as aerospace, automobile and in sports goods because of their high strength to weight ratio and renewability. Hence the study of mechanical behaviors of natural fiber composites is very important in using these composite laminates for such specific applications. This project aims at identifying the mechanical properties of hybrid natural Jute/Kenaf fiber. The major drawbacks in natural fiber are its Resin incompatibility. Surface treatment of fiber is made to improve the interfacial bonding between the fiber and resin and to reduce the moisture absorption. Laminates are fabricated using Hand lay-up technique. Mechanical properties such as tensile, flexural, and Impact test for jute/kenaf hybrid laminates were obtained. Specimen preparation and Mechanical property testing were carried out as per ASTM standards. Micro structures of the different layer of hybrid specimens are scanned by the Scanning Electron Microscope.

Similar content being viewed by others

References

I.D.G. ArySubagia, Yonjig Kim, Leonard D. Tijing, Cheol Sang Kim, Ho Kyong Shon, Composites: Part B, (2014)

Girisha K G, Anil K C & Akash A, Mechanical Properties Of Jute And Hemp Reinforced Epoxy/Polyester Hybrid Composites, International Journal of Engineering and Technology, 2347–4599,2014

Ramesh M, Palanikumar K, Hemachandra Reddy K (2013). Compos Part B 48:1–9

Nitta Y, Goda K, Noda J, Lee W-II (2013). Compos Part A Appl Sci Manuf 49:132–138

Karthikeyan A, Balamurugan K (2012) Effect of alkali treatment and fiber length on impact behaviour of coir fiber reinforced epoxy composite. J Sci Ind Res 71:627–631

Kabir MM, Wang H, Lau KT, Cardona F, Aravinthan T (2012) Mechanical properties of chemically-treated hemp fiber reinforced sandwich composites. Composites: Part B 43:159–169

Malkapuram R, Kumar V, Yuvraj SN (2008). J Reinf Plast Compos 28:1169

Wambua P, Ivens J, Verpoest I (2003). Compos Sci Technol 63:1259

Sreekalaa MS, George Jayamol KMG, Sabu T (2002). Compos Sci Technol 62(3):339

Mishra S, Mohanty AK, Drzal LT, Misra M, Parijac S, Nayak SK (2003). Compos Sci Technol 63(10):1377

Maya J, Thomas S, Varghese KT (2004). Compos Sci Technol 4(7–8):955

Amirhossein E (2007). J Appl Sci 24(7):3943

Velmurugan R, Manikandan V (2007). Compos Part A 38(10):2216

Thiruchitrambalam M, Alavudeen A, Athijayamani A, Venkateshwaran N, Elayaperumal A (2009). Mater Phys Mech 8:165

Ahmad I, Baharum A, Abdullah I (2006). J Reinf Plast Compos 25:957

John MJ, Thomas S (2008). Carbohydr Polym 71:343

Corrales F, Vilaseca F, Llop M, Girones J, Mendez JA, Mutje P (2007). J Hazard Mater 144:730

Pejic BM, Kostic MM, Skundric PD, Praskalo JZ (2008). Bioresourc Technol 99:2686

Ray D, Sarkar BK (2001). J Appl Polym Sci 80:1013

Wong S, Shanks R, Hodzic A (2004). Compos Sci Technol 64:1321

Manikandan Nair KC, Thomas S, Groeninckx G (2001). Compos Sci Technol 61:2519

Katz J (1977). Patent Number 4(060):386

Rout J, Tripathy SS, Nayak SK, Misra M, Mohanty AK (2000). J Polym Sci Pol Chem 79(7):1169

Rout J, Misra M, Tripathy SS, Nayak SK, Mohanty AK (2001). Compos Sci Technol 61(9):1303

Shukla SR, Pai RS (2005). Bioresour Technol 96(13):1430

Mishra S, Mohanty AK, Drzal LT, Misra M, Parija MS, Nayak SK, Tripathy SS (2003). Compos Sci Technol 63:1377

Paul S, Puja N, Rajive G (2003). Molecules 8(4):374

Febrianto FD, Setyawati M, Karina B, Bakar S, Hadi YS (2006). J Biol Sci 6:337

Sabeel Ahmed K, Vijayarangan S (2008). Mater Process Tech 207:330

Alexandre G, Takanori M, Koichi G, Junji O (2007). Compos A Appl Sci Manuf 38:1811

Herrera Franco P, Valadez Gonzalez A, Cervantes Uc M (1997). Compos Part B Eng 28B:331

Anand P, Anbumalar V (2015). Polym (Korea) 39(1):46

Cao Y, Shibata S, Fukumoto I (2006). Compos A: Appl Sci Manuf 37:423–429

Herrera Franco PJ, Valadez Gonalez A (2005). Compos Part B Eng 36:597

Xue Y, Veazie DR, Glinsey C, Horstmeyer MF, Rowell RM (2007). Compos Part B Eng 38:152

Mallick PK, Broutman LJ (1977). J Test Eval 5:190

Cartie DDR, Irving PE (2002). Compos A: Appl Sci Manuf 33:483

Chen JK, Sun CT (1985). Compos Struct 4(1):59

Singh VK, Gope PC, Sakshi C, Singh BD (2012). J Mater Env Sci 3(1):185

Maleque MA, Belal FY, Sapuan SM (2007). Arab J Sci Eng 32:359

Roe PJ, Ansell MP (1985). J Mater Sci 20:4015

Mylsamy K, Rajendran I (2011). Mater Des 32:3076

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anand, P., Rajesh, D., Senthil Kumar, M. et al. Investigations on the performances of treated jute/Kenaf hybrid natural fiber reinforced epoxy composite. J Polym Res 25, 94 (2018). https://doi.org/10.1007/s10965-018-1494-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1494-6