Abstract

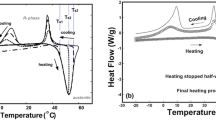

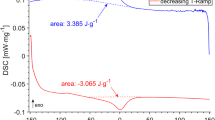

The temperature memory effect (TME) in differential scanning calorimeter test of a thermoplastic polyurethane is investigated in two ways: one is termed TME1, in which the material is cooled down for full crystallization during thermal cycling; while the other is termed TME2, in which the material is cooled, but before any crystallization occurs. In the case of single heating stop temperature (Ts), for TME1, the temperature gap (△T) is almost a constant; while for TME2, △T roughly increases in a linear manner with the increase of Ts. We also extend the study to multiple heating stops (upon to four stops) in TME2. It is confirmed that a higher heating stop temperature is able to eliminate the influence of the previous heating cycles if their corresponding heating stop temperature is lower. It is concluded that in all tests (for both TME1 and TME2), △T may be estimated as Ts + 1.6 °C with an accuracy of about ±0.5 °C or 4.1 %. A schematic sketch to reveal the origin of △T is presented.

Similar content being viewed by others

References

Tang C, Wang T, Huang W, Sun L, Gao X (2016) Temperature sensors based on the temperature memory effect in shape memory alloys to check minor over-heating. Sensors Actuator A Phys 238:337–343

Airoldi G, Corsi A, Riva G (1993) Micromemory effects in shape memory alloys. Nuovo Cimento D 15:365–374

Funakubo H (1987) Shape memory alloys. Gordon and Breach Science Publishers, New York

Otsuka K, Wayman CM (1998) Shape memory materials. Cambridge University Press, Cambridge

Huang WM, Ding Z, Wang CC, Wei J, Zhao Y, Purnawali H (2010) Shape memory materials. Mater Today 13:54–61

He Q, Huang WM, Hong MH, Wu MJ, Chong TC, Chellet F, et al. (2004) Characterization of sputtering deposited NiTi shape memory thin films using a temperature controllable atomic force microscope. Smart Mater Struct 13:977–982

Wu MJ (2009) Surface metrology and optical properties of thin film shape memory alloys. Nanyang Technological University, Singapore

Fu YQ, Sanjabi S, Barber ZH, Huang WM, Cai M, Zhang S, et al. (2008) In-situ observation of transition between surface relief and wrinkling in thin film shape memory alloys. J Nanosci Nanotechnol 8:2588–2596

Cai M, Fu YQ, Sanjabi S, Barber ZH, Dickinson JT (2007) Effect of composition on surface relief morphology in TiNiCu thin films. Surf Coat Technol 201:5843–5849

Wang ZG, Zu XT (2005) Effect of incomplete transformation on the transformation behavior in TiNi shape memory alloys. J Mater Sci 40:2663–2665

Airoldi G, Corsi A, Riva G (1998) Step-wise martensite to austenite reversible transformation stimulated by temperature or stress: a comparison in NiTi alloys. Mater Sci Eng A 241:233–240

Wang ZG, Zu XT, Zhu S, Wang LM (2005) Temperature memory effect induced by incomplete transformation in TiNi shape memory alloy. Mater Lett 59:491–494

Wang ZG, Zu XT, Yu HJ, He X, Peng C, Huo Y (2006) Temperature memory effect in CuAlNi single crystalline and CuZnAl polycrystalline shape memory alloys. Thermochim Acta 448:69–72

Liu N, Huang WM (2006) DSC study on temperature memory effect of NiTi shape memory alloy. Trans Nonferrous Metal Soc China 16:S37–S41

Liu N, Huang WM (2006) Comments on “incomplete transformation induced multiple-step transformation in TiNi shape memory alloys” [scripta mater 2005;53:335]. Scr Mater 55:493–495

Sun L, Huang WM, Cheah JY (2010) The temperature memory effect and the influence of thermo-mechanical cycling in shape memory alloys. Smart Mater Struct 19:055005

Krishnan M (2005) New observations on the thermal arrest memory effect in Ni-Ti alloys. Scr Mater 53:875–879

Madangopal KT, Banerjee S, Lele S (1994) Thermal arrest memory effect. Acta Metall Mater 42:1875–1885

Shahinpoor M (2005) Shape memory alloy temperature sensor. Patent No. US 6,837,620 B2

Huang W (1998) Effects of internal stress and martensite variants on phase transformation of NiTi shape memory alloy. J Mater Sci Lett 17:1843–1844

Miyazaki S, Fu YQ, Huang WM (2009) Thin film shape memory alloys: fundamentals and device applications. Cambridge University Press, New York

Miyazaki S, Otsuka K (1986) Deformation and transition behavior associated with the R -phase in Ti-Ni alloys. Metall Mater Trans A Phys Metall Mater Sci 17:53–63

Sun L, Huang WM, Ding Z, Zhao Y, Wang CC, Purnawali H, et al. (2012) Stimulus-responsive shape memory materials: a review. Mater Des 33:577–640

Sun L, Huang WM (2010) Mechanisms of the multi-shape memory effect and temperature memory effect in shape memory polymers. Soft Matter 6:4403–4406

Miaudet P, Derré A, Maugey M, Zakri C, Piccione PM, Inoubli R, et al. (2007) Shape and temperature memory of nanocomposites with broadened glass transition. Science 318:1294–1296

Xie T, Page KA, Eastman SA (2011) Strain-based temperature memory effect for nafion and its molecular origins. Adv Funct Mater 21:2057–2066

Huang WM, Zhao Y, Wang CC, Ding Z, Purnawali H, Tang C, et al. (2012) Thermo/chemo-responsive shape memory effect in polymers: a sketch of working mechanisms, fundamentals and optimization. J Polym Res 19:9952

Wu X, Huang WM, Zhao Y, Ding Z, Tang C, Zhang J (2013) Mechanisms of the shape memory effect in polymeric materials. Polymers 5:1169–1202

Purnawali H, Xu WW, Zhao Y, Ding Z, Wang CC, Huang WM, et al. (2012) Poly(methyl methacrylate) for active disassembly. Smart Mater Struct 21:075006

Sun L, Huang WM, Lu HB, Wang CC, Zhang JL (2014) Shape memory technology for active assembly/disassembly: fundamentals, techniques and example applications. Assem Autom 34:78–93

Yang WG, Lu HB, Huang WM, Qi HJ, Wu XL, Sun KY (2014) Advanced shape memory technology to reshape product design, manufacturing and recycling. Polymers 6:2287–2308

Lu H, Huang WM, Wu XL, Ge YC, Zhang F, Zhao Y, et al. (2014) Heating/ethanol-response of poly methyl methacrylate (PMMA) with gradient pre-deformation and potential temperature sensor and anti-counterfeit applications. Smart Mater Struct 23:067002

Sun L, Huang WM, Wang CC, Zhao Y, Ding Z, Purnawali H (2011) Optimization of the shape memory effect in shape memory polymers. J Polym Sci A Polym Chem 49:3574–3581

Sun L, Huang WM, Lu H, Lim KJ, Zhou Y, Wang TX, et al. (2014) Heating-responsive shape-memory effect in thermoplastic polyurethanes with low melt-flow index. Macromol Chem Phys 215:2430–2436

Zhu JJ, Huang WM, Liew KM (2003) Deformation energy in martensitic transformation. J Phys IV 112:179–182

Zhu JJ, Liang NG, Huang WM, Liew KM, Liu ZH (2002) A thermodynamic constitutive model for stress induced phase transformation in shape memory alloys. Int J Solids Struct 39:741–763

Mura T (2013) Micromechanics of defects in solids. Springer Science & Business Media, New York

Zhou Y, Huang WM, Zhao Y, Ding Z, Li Y, Tor SB, et al. (2016) Memory phenomenon in a lanthanum based bulk metallic glass. J Alloys Compd. doi:10.1016/j.jallcom.2016.02.114

An L, Huang WM (2006) Transformation characteristics of shape memory alloys in a thermal cycle. Mater Sci Eng A 420:220–227

Acknowledgments

This project is partially supported by National Natural Science Foundation of China (51578347) PR China, and Shanghai Natural Science Foundation (No. 15ZR1428200), PR China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, L., Wang, T.X., Leow, W.C. et al. Temperature memory effect in differential scanning calorimeter test in thermoplastic polyurethane. J Polym Res 23, 63 (2016). https://doi.org/10.1007/s10965-016-0958-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-0958-9