Abstract

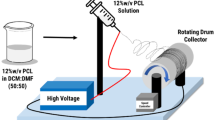

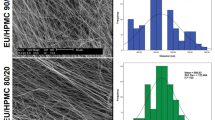

Poly(L-lactic acid) (PLLA) fiber mats containing a crude extract of Garcinia cowa Roxb. (GC) were prepared by electrospinning. The extract was introduced at a level of either at 30 or 50 % with respect to the weight of PLLA. The fibers of both the neat and the GC-loaded PLLA fibers were smooth, with average diameters of 0.80–1.13 μm. The characteristics of the release of GC from the GC-loaded PLLA fiber mats were assessed by a total immersion method in acetate or phosphate buffer solution that contained 0.5 % v/v Tween 80 and 3 % v/v methanol (hereafter, A/T/M or P/T/M medium) at either 32 or 37 °C, respectively. The maximum cumulative amount of GC released from the GC-loaded PLLA fiber mats in the P/T/M medium was greater than that released in the A/T/M medium. The antioxidant activity of the GC-loaded PLLA fiber mats, assessed using a 1,1-diphenyl-2-picrylhydrazyl (DPPH) assay, remained even after they had been exposed to a high electrical potential. The antimicrobial activity of the GC-loaded mats was greatest against Straphylococcus aureus ATCC 25923 and Straphylococcus aureus DMST 20654. Lastly, almost all of the GC-loaded PLLA fiber mats, except for those that contained 50 % GC, were found to be nontoxic to normal human dermal fibroblasts.

Similar content being viewed by others

References

Reneker DH, Yarin AL (2008) Polymer 49:2387–2425

Suwantong O, Ruktanonchai U, Supaphol P (2008) Polymer 49:4239–4247

Sikareepaisan P, Suksamrarn A, Supaphol P (2008) Nanotechnology 19:015102

Torres Vargas EA, do Vale Baracho NC, de Brito J, de Queiroz AAA (2010) Acta Biomater 6:1069–1078

Rujitanaroj P, Pimpha N, Supaphol P (2008) Polymer 49:4723–4732

del Valle LJ, Roa M, Díaz A, Casas MT, Puiggalí J, Rodríguez-Galán A (2012) J Polym Res 19:9792

Shalumon KT, Binulal NS, Selvamurugan N, Nair SV, Menon D, Furuike T, Tamura H, Jayakumar R (2009) Carbohyd Polym 77:863–869

Meng ZX, Wang YS, Ma C, Zheng W, Li L, Zheng YF (2010) Mater Sci Eng C 30:1204–1210

Wu X, Branford-White CJ, Zhu L, Chatterton NP, Yu D (2010) J Mater Sci Mater Med 21:2403–2411

Suwantong O, Opanasopit P, Ruktanonchai U, Supaphol P (2007) Polymer 48:7546–7557

Im JS, Yun J, Lim Y, Kim H, Lee Y (2010) Acta Biomater 6:102–109

Park J-Y, Lee I-H (2011) J Polym Res 18:1287–1291

Pornsopone V, Supaphol P, Rangkupan R, Tantayanon S (2007) J Polym Res 14:53–59

Baji A, Mai Y, Wong S, Abtahi M, Chen P (2010) Compos Sci Technol 70:703–718

Lyons J, Li C, Ko F (2004) Polymer 45:7597–7603

Renouf-Glauser AC, Rose J, Farrar DF, Cameron RE (2005) Biomaterials 26:5771–5782

Yang F, Murugan R, Wang S, Ramakrishna S (2005) Biomaterials 26:2603–2610

He L, Liao S, Quan D, Ma K, Chan C, Ramakrishna S, Lu J (2010) Acta Biomater 6:2960–2969

Maretschek S, Greiner A, Kissel T (2008) J Control Release 127:180–187

Kontogiannopoulos KN, Assimopoulou AN, Tsivintzelis I, Panayiotou C, Papageorgiou VP (2011) Int J Pharm 409:216–228

Kurpinski KT, Stephenson JT, Janairo RRR, Lee H, Li S (2010) Biomaterials 31:3536–3542

Zeng J, Yang L, Liang Q, Zhang X, Guan H, Xu X, Chen X, Jing X (2005) J Control Release 105:43–51

Zong X, Kim K, Fang D, Ran S, Hsiao BS, Chu B (2002) Polymer 43:4403–4412

Kenawy E, Bowlin GL, Mansfield K, Layman J, Simpson DG, Sanders EH, Wnek GE (2002) J Control Release 81:57–64

Chuysinuan P, Chimnoi N, Techasakul S, Supaphol P (2009) Macromol Chem Physic 210:814–822

Na Pattalung P, Thongtheeraparp W, Wiriyachitra P, Taylor WC (1994) Planta Med 60:365–368

Poomipamorn S, Kumkong A (1997) Edible multipurpose tree species. FuangFa, Bangkok, p 486 (in Thai)

Ilham M, Yaday M, Norhanom AW (1995) Nat Prod Sci 1:31–42

Murakami A, Jiwajiinda S, Koshimizu K, Ohigashi H (1995) Cancer Lett 95:137–146

Negi PS, Jayaprakasha GK, Jena BS (2008) LWT Food Sci Technol 41:1857–1861

Panthong K, Hutadilok-Towatana N, Panthong A (2009) Can J Chem 87:1636–1640

Xu G, Kan WLT, Zhou Y, Song J, Han Q, Qiao C, Cho C, Rudd JA, Lin G, Xu H (2010) J Nat Prod 73:104–108

Panthong K, Pongcharoen W, Phongpaichit S, Taylor WC (2006) Phytochemistry 67:999–1004

Likhitwitayawuid K, Phadungcharoen T, Krungkrai J (1998) Planta Med 64:70–72

Mahabusarakam W, Chairerk P, Taylor WC (2005) Phytochemistry 66:1148–1153

Robert RE, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Free Rad Bio Med 26:1231–1237

Philip LR, Peppas NA (1987) J Control Release 5:23–36

Peppas NA, Khare AR (1993) Adv Drug Delivery Rev 11:1–35

Verreck G, Chun I, Rosenblatt J, Peeters J, Dijck AV, Mensch J, Noppe M, Brewster ME (2003) J Control Release 92:349–360

Acknowledgments

This work was supported by the Thailand Research Fund (grant number: MRG5380120). We are grateful to Mae Fah Luang University for its partial financial support and allowing us to use its laboratory facilities. The authors acknowledge that they were partially financially supported by the “Integrated Innovation Academic Center: IIAC,” Chulalongkorn University Centenary Academic Development Project, Chulalongkorn University, which was used to procure the electrospinning apparatus used in this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 57 kb)

Rights and permissions

About this article

Cite this article

Suwantong, O., Pankongadisak, P., Deachathai, S. et al. Electrospun poly(L-lactic acid) fiber mats containing a crude Garcinia cowa extract for wound dressing applications. J Polym Res 19, 9896 (2012). https://doi.org/10.1007/s10965-012-9896-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-012-9896-3