Abstract

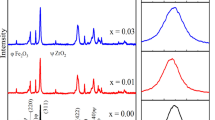

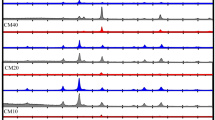

(NiCuZn)Fe2O4 ferrite is a kind of soft magnetic material widely used in multilayer chip inductors because of its high resistivity and excellent magnetic properties at high frequencies. In this study, (Ni0.4Cu0.2Zn0.4)Fe2O4 ferrite powder was prepared by ultrasonic-assisted chemical co-precipitation method, the effect of calcination temperature on the structure and properties of ferrite powders was investigated by modern analytical methods that include differential thermal analysis, X-ray diffraction, transmission electron microscopy, infrared spectroscopy, and vibrating sample magnetometer, respectively. The results show that the grain size increased from 23.5 nm to 38.6 nm and the lattice size increased from 8.384 Å to 8.390 Å with the increase of calcination temperature from 600°C to 900°C. The TEM shows that the powder particle was uniform and dispersible, and the particle size was about 30nm at 800°C calcination. The saturation magnetization of ferrite powder increases from 45.85emu/g to 50.65emu/g and the coercivity decreases from 65.50Oe to 46.23Oe with the increase of calcination temperature from 700°C to 900°C. The uniform and fine nano-crystalline ferrite particles would reduce the sintering temperature and improve the stability of the properties for spinel ferrite. The preparation of nano-spinel ferrite by ultrasonic-assisted co-precipitation is a worthy wet process for application.

Similar content being viewed by others

References

Jadhav, S.A., Somvanshi, S.B., Khedkar, M.V., Patade, S.R., Jadhav, K.M.: J. Mater. Sci. Mater. El. 31, 11352–11365 (2020)

Ismail, M.M., Jaber, N.A.: J. Supercond. Nov. Magn. 31, 1917–1923 (2018)

Hsiang, H.I., Lyu, B.J., Mei, L.T., Hsi, C.S.: J. Eur. Ceram. Soc. 36, 1191–1195 (2016)

Kannan, Y.B., Saravanan, R., Srinivasan, N., Praveena, K., Sadhana, K.: Physica B. 502, 181–186 (2016)

Ghasemi, A., Ghasemi, E., Paimozd, E.: J Magn. Magn. Mater. 323, 1541–1545 (2011)

Akhtar, M.N., Khan, M.A., Ahmad, M., Nazir, M.S., Imran, M., Ali, A., Sattar, A., Murtaza, G.: J. Magn. Magn. Mater. 421, 260–268 (2017)

Shrotri, J.J., Kulkarni, S.D., Deshpande, C.E., Mitra, A., Sainkar, S.R., Kumar, P.S.A., Date, S.K.: Mater. Chem. Phys. 59, 1–5 (1999)

Hamad, M.A., Hemeda, O.M., Mohamed, A.M.: Nov. Magn. 33, 2521–2525 (2020)

Anthony, R., Wang, N.N., Casey, D.P., Mathúna, C.Ó., Rohan, J.F.: J. Magn. Magn. Mater. 406, 89–94 (2016)

Hao, A.Z., Jia, D.Z., Ismail, M., Chen, R.Q., Bao, D.H.: J. Alloy. Compd. 790, 70–77 (2019)

Jasrotia, R., Puri, P., Verma, A., Singh, V.P.: J. Solid State Chem. 289, 121462 (2020)

Virlan, C., Tudorache, F., Pui, A.: Arab. J. Chem. 13, 2066–2075 (2020)

Su, H., Luo, Q., Jing, Y.L., Li, Y.X., Zhang, H.W., Tang, X.L.: J. Magn. Magn. Mater. 469, 419–427 (2019)

Guo, L., Li, J., Yang, Y., Wang, G., Rao, Y.H., Gan, G.W., Zhang, H.W.: J. Mater. Sci-Mater. El. 30, 15437–15443 (2019)

Wang, X.Y., Zhang, D.N., Wang, G., Jin, L.C., Li, J., Liao, Y.L., Zhang, H.W., Wang, S.Y.: Ceram. Int. 46, 10652–10657 (2020)

Wang, Y., Zhou, H., Qi, H.: Ceram. Int. 41, 12253–12257 (2015)

Kim, J.S., Ham, C.W.: Mater. Res. Bull. 44, 633–637 (2009)

Wu, X.H., Yan, S.Q., Liu, W.H., Feng, Z.K., Chen, Y.J., Harris, V.G.: J. Magn. Magn. Mater. 401, 1093–1096 (2016)

Hsiang, H.I., Hsi, C.S., Lin, R.L., Chiang, C.Y.: Mater. Chem. Phys. 151, 295–300 (2015)

Krishnaveni, T., Kanth, B.R., Raju, V.S.R., Murthy, S.R.: J. Alloy. Compd. 414, 282–286 (2006)

Kumar, S.J., Prameela, P., Rao, K.S., Kiran, J.N., Rao, K.H.: J. Supercond. Nov. Magn. 33, 693–705 (2020)

Yang, S.W., Jeong, K.P., Kim, J.G.: Adv. Mater. Sci. Eng. 2017, 2619749 (2017)

Kabbur, S.M., Nadargi, D.Y., Kambale, R.C., Ghodake, U.R., Suryavanshi, S.S.: J. Magn. Magn. Mater. 517, 167376 (2021)

Ramakrishna, K.S., Srinivas, C., Meena, S.S., Tirupanyam, B.V., Bhatt, P., Yusuf, S.M., Prajapat, C.L., Potukuchi, D.M., Sastry, D.L.: Ceram. Int. 43, 7984–7991 (2017)

Hou, W.X., Wang, Z.: Mater. Sci. Eng. B. 199, 57–61 (2015)

Ghasemi, A.: J. Magn. Magn. Mater. 360, 41–47 (2014)

Wang, H.B., Liu, J.H., Li, W.F., Wang, J.B., Wang, L., Song, L.J., Yuan, S.J., Li, F.S.: J. Alloy. Compd. 461, 373–377 (2008)

Harzali, H., Marzouki, A., Saida, F., Megriche, A., Mgaidi, A.: J. Magn. Magn. Mater. 460, 89–94 (2018)

Harzali, H., Saida, F., Marzouki, A., Megriche, A., Baillon, F., Espitalier, F.: J. Magn. Magn. Mater. 419, 50–56 (2016)

Sujatha, C., Reddy, K.V., Babu, K.S.: Ceram. Int. 39, 3077–3086 (2013)

Reddy, M.P., Balakrishnaiah, G., Madhuri, W., Ramana, M.V., Reddy, N.R., Kumar, K.V.S., Murthy, V.R.K., Reddy, R.R.: J. Phys. Chem. Solids. 71, 1373–1380 (2010)

Yang, M., Jin, R.J., Wang, Z.H., Liu, J.L., Barua, R., Song, X.L., Zhang, M.: J. Alloy. Compd. 820, 153429 (2020)

Almessiere, M.A., Slimani, Y., Kurtan, U., Guner, S., Sertkol, M., Shirsath, S.E., Akhtar, S., Baykal, A., Ercan, I.: Ultrason. Sonochem. 58, 104638 (2019)

Slimani, Y., Almessiere, M.A., Korkmaz, A.D., Guner, S., Güngüneş, H., Sertkol, M., Manikandan, A., Yildiz, A., Akhtar, S., Shirsath, S.E., Baykal, A.: Ultrason. Sonochem. 59, 104757 (2019)

Slimani, Y., Unal, B., Almessiere, M.A., Korkmaz, A.D., Shirsath, S.E., Yasin, G., Trukhanov, A.V., Baykal, A.: Results Phys. 17, 103061 (2020)

Almessiere, M., Slimani, Y., Korkmaz, A., Guner, S., Sertkol, M., Shirsath, S.E., Baykal, A.: Ultrason. Sonochem. 54, 1–10 (2019)

Peng, Y.D., Xia, C., Cui, M.H., Yao, Z.X., Yi, X.W.: Ultrason. Sonochem. 71, 105369 (2021)

Li, X., Wang, G.S.: J. Magn. Magn. Mater. 321, 1276–1279 (2009)

Aphesteguy, J.C., Jacobo, S.E., Schegoleva, N.N., Kurlyandskaya, G.V.: J. Alloy. Compd. 495, 509–512 (2010)

Kim, C.W., Koh, J.G.: J. Magn. Magn. Mater. 257, 355–368 (2003)

Xia, A.L., Jin, C.G., Du, D.X., Zhu, G.H.: J. Magn. Magn. Mater. 323, 1682–1685 (2011)

Yadav, R.S., Kuřitka, I., Vilcakova, J., Jamatia, T., Machovsky, M., Skoda, D., Urbánek, P., Masař, M., Urbánek, M., Kalina, L., Havlica, J.: Ultrason. Sonochem. 61, 104839 (2020)

Cao, M.S.: Science and Technology of ultrafine particle preparation. Harbin Institute of Technology Press, Harbin (1998)

Almessiere, M.A., Slimani, Y., Guner, S., Sertkol, M., Korkmaz, A.D., Shirsath, S.E., Baykal, A.: Ultrason. Sonochem. 58, 104654 (2019)

Borade, R.M., Somvanshi, S.B., Kale, S.B., Pawar, R.P., Jadhav, K.M.: Mater. Res. Express. 7, 016116 (2020)

Batoo, K.M., Ansari, M.S.: Nanoscale res. Lett. 7, 1–14 (2012)

Lu, X.G., Liang, G.Y., Sun, Q.J., Yang, C.H.: Mater. Lett. 65, 674–676 (2011)

Acknowledgments

This project was supported by Hunan Provincial Natural Science Foundation of China (2018JJ2515), and the State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yi, X., Cui, M., Peng, Y. et al. Influence of Calcination Temperature on Microstructure and Properties of (NiCuZn)Fe2O4 Ferrite Prepared via Ultrasonic-Assisted Co-Precipitation. J Supercond Nov Magn 34, 1245–1252 (2021). https://doi.org/10.1007/s10948-021-05835-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-021-05835-9