Abstract

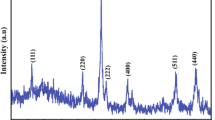

The high-purity FeCo particles with particle size ranging from 100 nm to 5 μm are fabricated using a direct chemical method. The controlled morphologies of the FeCo samples vary from nearly-spherical to urchin-like or cubic shape under optimal reaction conditions. Very slight surface oxidation is observed in these large-grain FeCo particles. It shows a low coercivity with 91 Oe for the nearly-spherical FeCo particles, while a much higher coercivity of 236 Oe is observed in the urchin-like samples, which can be mainly ascribed to their different morphologies and particle sizes. High saturation magnetization of 205–211 A/m2/kg can be achieved in these micron-level FeCo particles due to their high purity and single body-centered cubic (bcc) phase structure. The composition-controlled FeCo particles with different Fe/Co atom ratios can be obtained by adjusting the reaction temperature, which results in their variable saturation magnetization. The relative simple and low-cost chemical synthesis of large-grain FeCo particles promise their potential use in complicated shape and miniaturized FeCo-based magnetic components.

Similar content being viewed by others

References

Yu, R.H., Basu, S., Ren, L., Zhang, Y., Parvizi-Majidi, A., Unruh, K.M., Xiao, J.Q.: IEEE. Trans. Magn. 36, 3388 (2000)

Roy, R.K., Shen, S., Kernion, S.J., McHenry, M.E.: J. Appl. Phys. 111, 07A301 (2012)

Azizi, A., Sadrnezhaad, S.K., Hasani, A.: J. Magn. Magn. Mater. 322, 3551 (2010)

Díaz-Ortiz, A., Drautz, R., Fähnle, M., Dosch, H., Sanchez, J.M.: Phy. Rev. B 73, 224208 (2006)

Sundar, R.S., Deevi, S.C.: Intermetallics 12, 921 (2004)

Sundar, R.S., Deevi, S.C.: Int. Mater. Rev. 50, 157 (2005)

Kohara, T., Yamada, T., Abe, S., Kohno, S., Kaneko, F., Takemura, Y.: J. Appl. Phys. 109, 07E531 (2011)

Li, R., Liu, G., Stoica, M., Eckert, J.: Intermetallics 18, 134 (2010)

Hou, C.Q., Shan, Y.J., Wu, H.C., Bi, X.F.: J. Alloy. Compd. 556, 51 (2013)

Thirumal, E., Prabhu, D., Chattopadhyay, K., Ravichandran, V.: Phys. Status. Solidi. A 207, 2505 (2010)

Yan, S.J., Zhen, L., Xu, C.Y., Jiang, J.T., Shao, W.Z., Phys, J.: D: Appl. Phys. 43, 245003 (2010)

Yang, Y., Xu, C.L., Xia, Y.X., Wang, T., Li, F.S.: J. Alloy. Compd. 493, 549 (2010)

Chen, M., Yamamuro, S., Farrell, D., Majetich, S.A.: J. Appl. Phys. 93, 7551 (2003)

Hao, R., Xing, R.J., Xu, Z.C., Hou, Y.L., Gao, S., Sun, S.H.: Adv. Mater. 22, 2729 (2010)

Chaubey, G.S., Barcena, C., Poudyal, N., Rong, C.B., Gao, J.M., Sun, S.H., Liu, J.P.: J. Am. Chem. Soc. 129, 7214 (2007)

Mendoza-Reséndez, R., Luna, C., Barriga-Castro, E.D., Bonville, P., Serna, C.J.: Nanotechnology 23, 225601 (2012)

Alikhanzadeh-Arani, S., Salavati-Niasari, M., Almasi-Kashi, M.: J. Magn. Magn. Mater. 324, 3652 (2012)

Wen, M., Meng, X.G., Sun, B.L., Wu, Q.S., Chai, X.L.: Inorg. Chem. 50, 9393 (2011)

Qin, D.H., Cao, L., Sun, Q.Y., Huang, Y., Li, H.L.: Chem. Phys. Lett. 358, 484 (2002)

Yang, W., Cui, C.X., Sun, J.B., Wang, B.L.: J. Mater. Sci. 45, 1523 (2010)

Elbaile, L., Crespo, R.D., Vega, V., García, J.A.: J. Nanomater. 2012, 198453 (2012)

Liao, Q.L., Tannenbaum, R., Wang, Z.L.: J. Phys. Chem. B 110, 14262 (2006)

Elkins, K.E., Vedantam, T.S., Liu, J.P., Zeng, H., Sun, S.H., Ding, Y., Wang, Z.L.: Nano. Lett. 3, 1647 (2003)

Liu, D.Y., Ren, S., Wu, H., Zhang, Q.T., Wen, L.S.: J. Mater. Sci. 43, 1974 (2008)

Gota, S., Guiot, E., Henriot, M., Gautier-Soyer, M.: Phys. Rev. B 60, 14387 (1999)

Yamashita, T., Hayes, P.: Appl. Surf. Sci. 254, 2441 (2008)

Núñez, N.O., Tartaj, P., Morales, M.P., Bonville, P., Serna, C.J.: Chem. Mater. 16, 3119 (2004)

Chen, W., Pechenik, A., Dapkunas, S.J., Piermarini, G.J., Malghan, S.G.: J. Am. Ceram. Soc. 77, 1005 (1994)

Maurer, T., Ott, F., Chaboussant, G., Soumare, Y., Piquemal, J.Y., Viau, G.: Appl. Phys. Lett. 91, 172501 (2007)

Wei, X.W., Zhu, G.X., Liu, Y.J., Ni, Y.H., Song, Y., Xu, Z.: Chem. Mater. 20, 6248 (2008)

Acknowledgments

This work was supported by Beijing Natural Science Foundation under Grant No. 2132039, the National Nature Science Foundation of China under Grant No. 51101007, and the National Basic Research Program of China (973 Program) under Grant No. 2010CB934602.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Y., Yang, B., Yang, X. et al. Controlled Morphologies and Intrinsic Magnetic Properties of Chemically Synthesized Large-Grain FeCo Particles. J Supercond Nov Magn 28, 1863–1869 (2015). https://doi.org/10.1007/s10948-015-2980-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-015-2980-2