Abstract

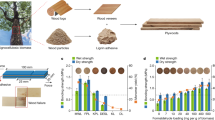

Lignin was modified by degradation to have more high active sites. Depolymerized lignin-based phenolic resin was synthesized to protect the environment and reduce the cost. Under the optimal conditions of sodium hydroxide catalysis, the effect of different concentrations of Na2S2O3 on the depolymerization of lignin was studied by the microwave depolymerization and the hydrothermal reaction. The depolymerized lignin had the highest phenolic hydroxyl content of 22.41% and 22.35% by two methods, respectively. LC-HRMS showed that the molecular weights of the depolymerized lignin decreased significantly. SEM showed that the surface of the depolymerized lignin-based phenolic resin was smooth and tightly connected. The adhesive had the highest bonding strength of 2.94 MPa. When lignin replaced 100 wt% phenol, the bonding strength of this adhesive could reach 1.57 MPa. This showed that when the lignin with complex structures was degraded, industrial adhesives with high bonding strength could be successfully obtained.

Similar content being viewed by others

References

Kai D, Tan MJ, Chee PL et al (2016) Towards lignin-based functional materials in a sustainable world. Green Chem 18:1175–1200.

Saito T, Brown RH, Hunt Ma et al (2012) Turning renewable resources into value-added polymer: development of lignin-based thermoplastic. Green Chem 14:3295–3303.

Zhang W, Ma Y, Wang et al (2013) Preparation and properties of lignin–phenol–formaldehyde resins based on different biorefinery residues of agricultural biomass. Ind Crops Prod 43:326–333.

Danielson B, Simonson R (1998) Kraft lignin in phenol formaldehyde resin. Part 2. Evaluation of an industrial trial. J Adhesion Sci Technol 12:941–946.

Xia J, Xue H, Gao R, et al (2020) Sustainable phenolic thermosets coatings derived from urushiol. Polym Eng Sci 61:489–496.

Zhang W, Ma Y, Xu Y et al (2013) Lignocellulosic ethanol residue-based lignin–phenol–formaldehyde resin adhesive. Int J Adhes Adhes 40:11–18.

Zhang Z, Mulyadi A, Kuang X et al (2019) Lignin-polystyrene composite foams through high internal phase emulsion polymerization. Polym Eng Sci 59:964–972.

Wong SS, Shu R, Zhang J et al (2020) Downstream processing of lignin derived feedstock into end products. Chem Soc Rev 49:5510–5560.

Wang G, Chen H (2014) Carbohydrate elimination of alkaline-extracted lignin liquor by steam explosion and its methylolation for substitution of phenolic adhesive. Ind Crops Prod 53:93–101.

Song Y, Wang X Z, Yan N (2016) Demethylation of wheat straw alkali lignin for application in phenol formaldehyde adhesives. Polymers 8:209.

Li J, Wang W, Zhang S et al (2016) Preparation and characterization of lignin demethylated at atmospheric pressure and its application in fast curing biobased phenolic resins. RSC Adv 6:67435–67443.

Kalami S, Arefmanesh M, Master E, Nejad M (2017) Replacing 100% of phenol in phenolic adhesive formulations with lignin. J Appl Polym Sci 45124:1–9.

Zhao M, Jing J, Zhu Y (2016) Preparation and performance of lignin–phenol–formaldehyde adhesives. Int J Adhes Adhes 64:163–167.

Ouyang X, Huang X, Ruan T, Qiu X (2015) Microwave-assisted oxidative digestion of lignin with hydrogen peroxide for TOC and color removal. Water Sci Technol 71: 390–396.

Kappe CO (2008) Microwave dielectric heating in synthetic organic chemistry. Chem Soc Rev 37:1127–1139.

Tsegaye B, Balomajumder C, Roy P (2019) Optimization of microwave and NaOH pretreatments of wheat straw for enhancing biofuel yield. Energ Convers Manage 186:82–92.

Aguilar-Reynosa A, Romaní A, Rodríguez-Jasso M et al (2017) Microwave heating processing as alternative of pretreatment in second-generation biorefinery: an overview. Energ Convers Manage 136:50–65.

Wei G, Liu Z, Zhang L, Li Z (2018) Catalytic upgrading of Jatropha oil biodiesel by partial hydrogenation using Raney-Ni as catalyst under microwave heating. Energ Convers Manage 163:208–218.

Di B, Li Z, Lei Y et al (2021) Phenol-enriched hydroxy depolymerized lignin by microwave alkali catalysis to prepare high adhesive biomass composites. Polym Eng Sci 61:1463–1475.

Muley PD, Mobley JK, Tong X et al (2019) Rapid microwave-assisted biomass delignification and lignin depolymerization in deep eutectic solvents. Energ Convers Manage 196:1080–1088.

Duan D, Ruan R, Wang Y et al (2018) Microwave-assisted acid pretreatment of alkali lignin: Effect on characteristics and pyrolysis behavior. Bioresour Technol 251:57–62.

Lee JS, Kim JH, Cho JE (2015) Isolation and characterization of lignin from the oak wood bioethanol production residue for adhesives. Int J Biol Macromol 72:1056–1062.

Zhao S, Chen X, Fan Z et al (2013) Using lignin degraded to synthesize phenolic foams with excellent flame retardant property. Coll Surf A Physicochem Eng Asp 666:131373

Li J, Zhang J, Zhang S et al (2018) Alkali lignin depolymerization under eco-friendly and cost-effective NaOH/urea aqueous solution for fast curing bio-based phenolic resin. Ind Crops Prod 120:25–33.

Yang W, Fortunati E, Gao D et al (2018) Valorization of acid isolated high yield lignin nanoparticles as innovative antioxidant/antimicrobial organic materials. ACS Sustain Chem Eng 6:3502–3514

Hong S, Lian H, Sun X et al (2016) Zinc-based deep eutectic solvent-mediated hydroxylation and demethoxylation of lignin for the production of wood adhesive. RSC Adv 6:89599–89608.

Du B, Liu B, Yang Y et al (2019) A phosphotungstic acid catalyst for depolymerization in bulrush lignin. Catalysts 9:2–15.

Shi Y, Zhu K, Dai Y et al (2020) Evolution and stabilization of environmental persistent free radicals during the decomposition of lignin by laccase. Chemosphere 248:125931.

Alma MH, Kelley SS (2000) Thermal stability of novolak-type thermosettings made by the condensation of bark and phenol. Polym Degrad Stab 68:413–418.

Lee SS, Chang K, Tseng IM (2012) Properties of phenol-formaldehyde resins prepared from phenol-liquefied lignin. J Appl Polym Sci 124:4782–4788.

Christiansen AW, Gollob L (1985) Differential scanning calorimetry of phenol-formaldehyde resols. J Appl Polym Sci 30:2279–2289.

Chen Y, Gong X, Yang G et al (2019) Preparation and characterization of a nanolignin phenol formaldehyde resin by replacing phenol partially with lignin nanoparticles. RSC Adv 9:29255–29262.

Wang H, Eberhardt TL, Wang C et al (2019) Demethylation of alkali lignin with halogen acids and its application to phenolic resins. Polymers 11:1–16.

Funding

This work was supported by Mingsheng Diatom New Materials Co., Ltd., China.

Author information

Authors and Affiliations

Contributions

SZ and BD: wrote the main manuscript text. ZF and RN: designed and performed the experiments. WX: applied the conceptualization and methodology. YT and XL: supervised experiments. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, S., Xu, W., Di, B. et al. Using Phenol-Enriched Hydroxy Lignin Obtained by Low-Cost Catalysts to Synthesize Industrial Adhesive. J Polym Environ 31, 4691–4702 (2023). https://doi.org/10.1007/s10924-023-02886-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02886-y