Abstract

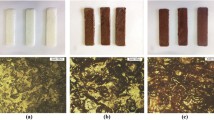

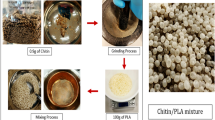

Macadamia is a nut widely used globally in food, personal hygiene products, and human health. After removing the nut, high amounts of the shell residual, which is an underutilized material with high economic interest. This work presents a sustainable alternative to revalorize the macadamia nutshell residues (MR) developing the green composites. Polypropylene (PP) composites were prepared using different MR content (5, 10, 15, 20, 25, and 30 wt%) as a filler. The samples were investigated by Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis, scanning electron microscopy (SEM), mechanical tests (tensile and flexure) before and after water absorption tests, and Life Cycle Assessment (LCA). FTIR results indicated that the MR acted only by physical impediments, without chemical interactions between the filler and matrix. Thermal analysis showed a significant increase (~ 20 °C) in PP thermal stability after MR addition, probably due to the filler high lignin content, and SEM photomicrographs indicate that high MR contents resulted in little cracks and voids in the interface. However, the defects did not influence the mechanical performance, and the green composites showed superior elastic modulus (2401 MPa) than the pristine PP (1516 MPa) and similar tensile strength (~ 30 MPa), confirmed by the statistical analysis and corroborating with the theoretical percolation network (25 wt%). The composites showed low water absorption (up to 0.3%), reflecting in downward variations in the wet samples' mechanical behavior. It evidences the possibility to use these samples for water applications. LCA indicated that higher MR contents promoted lower environmental impacts than the classical handling of this residue, and the results indicated that 30 wt% MR is the better environmental option. However, the PP/MR-25% showed reduced environmental impacts and associated with other properties improvements, considered the better sample. This work shows the MR revalorization as a sustainable approach to expand green composites applications.

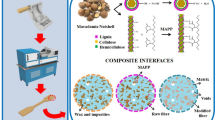

Graphic Abstract

Similar content being viewed by others

References

Akhtar MN, Sulong AB, Radzi MKF, Ismail NF, Raza MR, Muhamad N, Khan MA (2016) Influence of alkaline treatment and fiber loading on the physical and mechanical properties of kenaf/polypropylene composites for variety of applications. Prog Nat Sci Mater Int 26:657–664. https://doi.org/10.1016/j.pnsc.2016.12.004

Ayrilmis N, Taşdemir M, Akbulut T (2017) Water absorption and mechanical properties of PP/HIPS hybrid composites filled with wood flourAyrilmis, Nadir, Münir Taşdemir, and Turgay Akbulut. "Water absorption and mechanical properties of PP/HIPS hybrid composites filled with wood flour. Polym Compos 38:863–869

Bachmann J, Hidalgo C, Bricout S (2017) Environmental analysis of innovative sustainable composites with potential use in aviation sector—a life cycle assessment review. Sci China Technol Sci 60:1301–1317. https://doi.org/10.1007/s11431-016-9094-y

Bada SO, Falcon RMS, Falcon LM, Makhula MJ (2015) Thermogravimetric investigation of macadamia nut shell, coal, and anthracite in different combustion atmospheres. J S Afr Inst Min Metall 115:741–746. https://doi.org/10.17159/2411-9717/2015/v115n8a10

Balasundar P, Narayanasamy P, Senthil S, Abdullah Al-Dhabi N, Prithivirajan R, Shyam Kumar R, Ramkumar T, Subrahmanya Bhat K (2019) Physico-chemical study of pistachio (Pistacia vera) nutshell particles as a bio-filler for eco-friendly composites. Mater Res Express. https://doi.org/10.1088/2053-1591/ab3b9b

Beigbeder J, Soccalingame L, Perrin D, Bénézet JC, Bergeret A (2019) How to manage biocomposites wastes end of life? A life cycle assessment approach (LCA) focused on polypropylene (PP)/wood flour and polylactic acid (PLA)/flax fibres biocomposites. Waste Manag 83:184–193. https://doi.org/10.1016/j.wasman.2018.11.012

Binoj JS, Edwin Raj R, Daniel BSS (2017) Comprehensive characterization of industrially discarded fruit fiber, Tamarindus indica L. as a potential eco-friendly bio-reinforcement for polymer composite. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.09.179

Buffa JM, Mondragon G, Corcuera MA, Eceiza A, Mucci V, Aranguren MI (2018) Physical and mechanical properties of a vegetable oil based nanocomposite. Eur Polym J 98:116–124. https://doi.org/10.1016/j.eurpolymj.2017.10.035

Cao C (2017) Sustainability and life assessment of high strength natural fibre composites in construction. Advanced high strength natural fibre composites in construction. Elsevier, Amsterdam, pp 529–544

Castro BD, Fotouhi M, Vieira LMG, de Faria PE, Campos Rubio JC (2020) Mechanical behaviour of a green composite from biopolymers reinforced with sisal fibres. J Polym Environ. https://doi.org/10.1007/s10924-020-01875-9

Cholake ST, Rajarao R, Henderson P, Rajagopal RR, Sahajwalla V (2017) Composite panels obtained from automotive waste plastics and agricultural macadamia shell waste. J Clean Prod 151:163–171. https://doi.org/10.1016/j.jclepro.2017.03.074

Chong TY, Law MC, Chan YS (2020) The potentials of corn waste lignocellulosic fibre as an improved reinforced bioplastic composites. J Polym Environ. https://doi.org/10.1007/s10924-020-01888-4

Cipriano J, Zanini NC, Dantas IR, Mulinari DR (2019) Mechanical properties of polypropylene composites reinforced with macadamia nutshell fibers. J Renew Mater 7:1047–1053. https://doi.org/10.32604/jrm.2019.00001

Costa ILM, Monticeli FM, Mulinari DR (2020) Polyurethane foam reinforced with fibers pineaplle crown biocomposites for sorption of vegetable oil. Fibers Polym 21:1832–1840. https://doi.org/10.1007/s12221-020-9979-4

da Silva CG, Kano FS, dos Santos Rosa D (2019) Thermal stability of the PBAT biofilms with cellulose nanostructures/essential oils for active packaging. J Therm Anal Calorim 138:2375–2386. https://doi.org/10.1007/s10973-019-08190-z

Dantas IR, Zanini NC, Cipriano JP, Capri MR, Mulinari DR (2018) Influence of coupling agent on the properties of polypropylene composites reinforced with palm fibers. Adv Nat Fibre Compos. https://doi.org/10.1007/978-3-319-64641-1_5

Delogu M, Zanchi L, Maltese S, Bonoli A, Pierini M (2016) Environmental and economic life cycle assessment of a lightweight solution for an automotive component: a comparison between talc-filled and hollow glass microspheres-reinforced polymer composites. J Clean Prod 139:548–560. https://doi.org/10.1016/j.jclepro.2016.08.079

Dickson AR, Sandquist D (2018) Mode of wood fibre breakage during thermoplastic melt processing. Compos Part A Appl Sci Manuf 112:496–503. https://doi.org/10.1016/j.compositesa.2018.07.004

Dong C, Davies IJ, Fornari Junior CCM, Scaffaro R (2017) Mechanical properties of Macadamia nutshell powder and PLA bio-composites. Aust J Mech Eng 15:150–156. https://doi.org/10.1080/14484846.2016.1187245

Fan F, Yang Z, Li H, Shi Z, Kan H (2018) Preparation and properties of hydrochars from macadamia nut shell via hydrothermal carbonization. R Soc Open Sci. https://doi.org/10.1098/rsos.181126

Favier V, Dendievel R, Canova G, Cavaille JY, Gilormini P (1997) Simulation and modeling of three-dimensional percolating structures: case of a latex matrix reinforced by a network of cellulose fibers. Acta Mater 45:1557–1565. https://doi.org/10.1016/S1359-6454(96)00264-9

Fourati Y, Magnin A, Putaux JL, Boufi S (2020) One-step processing of plasticized starch/cellulose nanofibrils nanocomposites via twin-screw extrusion of starch and cellulose fibers. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2019.115554

Girdis J, Proust G, Löschke S, Dong A (2018) Upcycling macadamia nut shells: the effect of particle size and moisture content on 3D printed nutshell–plastic composites. J Eng Technol 5:3–8

Govil T, Wang J, Samanta D, David A, Tripathi A, Rauniyar S, Salem DR, Sani RK (2020) Lignocellulosic feedstock: a review of a sustainable platform for cleaner production of nature’s plastics. J Clean Prod 270:122521. https://doi.org/10.1016/j.jclepro.2020.122521

Gupta MK (2018) Water absorption and its effect on mechanical properties of sisal composite. J Chin Adv Mater Soc 6:561–572. https://doi.org/10.1080/22243682.2018.1522600

Han HC, Gong XL, Zhou M, Wu YP (2020) A study about water/alkali treatments of hemp fiber on ultraviolet ageing of the reinforced polypropylene composites. J Polym Environ 28:2572–2583. https://doi.org/10.1007/s10924-020-01799-4

Haque MMU, Puglia D, Fortunati E, Pracella M (2017) Effect of reactive functionalization on properties and degradability of poly(lactic acid)/poly(vinyl acetate) nanocomposites with cellulose nanocrystals. React Funct Polym 110:1–9. https://doi.org/10.1016/j.reactfunctpolym.2016.11.003

Islam MR, Gupta A, Rivai M, Beg MDH (2017) Characterization of microwave-treated oil palm empty fruit bunch/glass fibre/polypropylene composites. J Thermoplast Compos Mater 30:986–1002. https://doi.org/10.1177/0892705715614078

Jennings JS, Macmillan NH (1986) A tough nut to crack. J Mater Sci 21:1517–1524. https://doi.org/10.1007/BF01114704

Kumar U, Maroufi S, Rajarao R, Mayyas M, Mansuri I, Joshi RK, Sahajwalla V (2017) Cleaner production of iron by using waste macadamia biomass as a carbon resource. J Clean Prod 158:218–224. https://doi.org/10.1016/j.jclepro.2017.04.115

La Rosa AD, Blanco I, Banatao DR, Pastine SJ, Björklund A, Cicala G (2018) Innovative chemical process for recycling thermosets cured with recyclamines® by converting bio-epoxy composites in reusable thermoplastic-an LCA study. Materials (Basel). https://doi.org/10.3390/ma11030353

Lafia-Araga RA, Hassan A, Yahya R, Rahman NA, Salleh FM (2019) Water absorption behavior of heat-treated and untreated red balau saw dust/LDPE composites: its kinetics and effects on mechanical properties. J Thermoplast Compos Mater 32:1408–1426. https://doi.org/10.1177/0892705718799823

Lee CH, Sapuan SM, Hassan MR (2017) Mechanical and thermal properties of kenaf fiber reinforced polypropylene/magnesium hydroxide composites. J Eng Fiber Fabr 12:50–58. https://doi.org/10.1177/155892501701200206

Mansor MR, Mastura MT, Sapuan SM, Zainudin AZ (2018) The environmental impact of natural fiber composites through life cycle assessment analysis. Durability and life prediction in biocomposites fibre-reinforced composites and hybrid composites. Elsevier Ltd, Amsterdam, pp 257–285

Mariano M, El Kissi N, Dufresne A (2016) Structural reorganization of CNC in injection-molded CNC/PBAT materials under thermal annealing. Langmuir 32:10093–10103. https://doi.org/10.1021/acs.langmuir.6b03220

Martins LS, Maciel F, Mulinari DR (2020) Influence of the granulometry and fiber content of palm residues on the diesel S-10 oil sorption in polyurethane/palm fiber biocomposites. Results Mater. https://doi.org/10.1016/j.rinma.2020.100143

Moreno DDP, de Camargo RV, dos Santos Luiz D, Branco LTP, Grillo CC, Saron C (2020) Composites of recycled polypropylene from cotton swab waste with pyrolyzed rice husk. J Polym Environ. https://doi.org/10.1007/s10924-020-01883-9

Mulinari DR, Cipriano JP, Capri MR, Brandão AT (2018) Influence of surgarcane bagasse fibers with modified surface on polypropylene composites. J Nat Fibers 15:174–182. https://doi.org/10.1080/15440478.2016.1266294

Oladele IO, Ajileye JO, Oke SR, Daramola OO, Adewumi OA (2020) Thermal and water absorption properties of bio-synthetic hybrid reinforced polypropylene composites. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.05.580

Oliveira SA, Nunes de Macedo JR, dos Rosa D (2019) Eco-efficiency of poly (lactic acid)-starch-cotton composite with high natural cotton fiber content: environmental and functional value. J Clean Prod 217:32–41. https://doi.org/10.1016/j.jclepro.2019.01.198

Pakade VE, Ntuli TD, Ofomaja AE (2017) Biosorption of hexavalent chromium from aqueous solutions by Macadamia nutshell powder. Appl Water Sci 7:3015–3030. https://doi.org/10.1007/s13201-016-0412-5

Panaitescu DM, Nicolae CA, Vuluga Z, Vitelaru C, Sanporean CG, Zaharia C, Florea D, Vasilievici G (2016) Influence of hemp fibers with modified surface on polypropylene composites. J Ind Eng Chem 37:137–146. https://doi.org/10.1016/j.jiec.2016.03.018

Platnieks O, Barkane A, Ijudina N, Gaidukova G, Thakur VK, Gaidukovs S (2020) Sustainable tetra pak recycled cellulose/Poly(Butylene succinate) based woody-like composites for a circular economy. J Clean Prod 270:122321. https://doi.org/10.1016/j.jclepro.2020.122321

Rabma S, Narksitipan S, Jaitanong N (2020) Coconut fiber reinforced cement-based composites. Solid State Phenom 302:101–106. https://doi.org/10.4028/www.scientific.net/SSP.302.101

Ramesh P, Vinodh S (2020) State of art review on life cycle assessment of polymers. Int J Sustain Eng 00:1–12. https://doi.org/10.1080/19397038.2020.1802623

Schüler P, Speck T, Bührig-Polaczek A, Fleck C (2014) Structure–function relationships in Macadamia integrifolia seed coats - fundamentals of the hierarchical microstructure. PLoS ONE 9:1–14. https://doi.org/10.1371/journal.pone.0102913

Sesana R, Delprete C, Sangermano M (2019) Mechanical behavior of macadamia nutshells. Procedia Struct Integr 24:829–836. https://doi.org/10.1016/j.prostr.2020.02.088

Shao, X., He, L., Ma, L., 2016. Water absorption and FTIR analysis of three type natural fiber reinforced composites. pp 269–272. https://doi.org/10.2991/ifeea-15.2016.56

Sommerhuber PF, Wenker JL, Rüter S, Krause A (2017) Life cycle assessment of wood-plastic composites: analysing alternative materials and identifying an environmental sound end-of-life option. Resour Conserv Recycl 117:235–248. https://doi.org/10.1016/j.resconrec.2016.10.012

Song X, He W, Qin H, Yang S, Wen S (2020) Fused deposition modeling of poly (lactic acid)/macadamia composites-thermal, mechanical properties and scaffolds. Materials (Basel). https://doi.org/10.3390/ma13020258

Stanzione M, Oliviero M, Cocca M, Errico ME, Gentile G, Avella M, Lavorgna M, Buonocore GG, Verdolotti L (2020) Tuning of polyurethane foam mechanical and thermal properties using ball-milled cellulose. Carbohydr Polym 231:115772. https://doi.org/10.1016/j.carbpol.2019.115772

Suffo M, de la Mata M, Molina SI (2020) A sugar-beet waste based thermoplastic agro-composite as substitute for raw materials. J Clean Prod 257:120382. https://doi.org/10.1016/j.jclepro.2020.120382

Sun L, Wu Q, Xie Y, Song K, Lee S, Wang Q (2016) Thermal decomposition of fire-retarded wood flour/polypropylene composites: kinetic property and degradation mechanisms. J Therm Anal Calorim 123:309–318. https://doi.org/10.1007/s10973-015-4971-8

Tarrés Q, Soler J, Rojas-Sola JI, Oliver-Ortega H, Julián F, Espinach FX, Mutjé P, Delgado-Aguilar M (2019) Flexural properties and mean intrinsic flexural strength of old newspaper reinforced polypropylene composites. Polymers (Basel) 11:1–13. https://doi.org/10.3390/polym11081244

Tsolele R, Mtunzi FM, Klink MJ, Pakade VE (2019) An alternative low-cost adsorbent for gold recovery from cyanide-leached liquors: adsorption isotherm and kinetic studies. Adsorpt Sci Technol 37:3–23. https://doi.org/10.1177/0263617418802557

van Oers L, Guinée J (2016) The abiotic depletion potential: background, updates, and future. Resources. https://doi.org/10.3390/resources5010016

Várdai R, Lummerstorfer T, Pretschuh C, Jerabek M, Gahleitner M, Pukánszky B, Renner K (2019) Impact modification of PP/wood composites: a new approach using hybrid fibers. Express Polym Lett 13:223–234. https://doi.org/10.3144/expresspolymlett.2019.19

Wang W, Guo X, Zhao D, Liu L, Zhang R, Yu J (2020) Water absorption and hygrothermal aging behavior of wood-polypropylene composites. Polymers (Basel). https://doi.org/10.3390/POLYM12040782

Wongcharee S, Aravinthan V, Erdei L, Sanongraj W (2018) Mesoporous activated carbon prepared from macadamia nut shell waste by carbon dioxide activation: comparative characterisation and study of methylene blue removal from aqueous solution. Asia-Pacific J Chem Eng 13:1–16. https://doi.org/10.1002/apj.2179

Zanini NC, Barbosa RFS, de Souza AG, Rosa DS, Mulinari DR (2020) Revaluation of Australian palm residues in polypropylene composites: statistical influence of fiber treatment. J Compos Mater. https://doi.org/10.1177/0021998320960534

Acknowledgements

This research was funded by Fundação de Amparo à Pesquisa do Estado do Rio de Janeiro (Grant Nos. E-26/260.026/2018 and E-26/010.001800/2015), Fundação de Amparo à Pesquisa do Estado de São Paulo (Grant No. 2018/11277-7), and Conselho Nacional de Desenvolvimento Científico e Tecnológico (Grant No. 305819/2017-8). The authors thank the CAPES (Grant No. Code 001), UFABC, and REVALORES Strategic Unit.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cortat, L.O., Zanini, N.C., Barbosa, R.F.S. et al. A Sustainable Perspective for Macadamia Nutshell Residues Revalorization by Green Composites Development. J Polym Environ 29, 3210–3226 (2021). https://doi.org/10.1007/s10924-021-02080-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02080-y