Abstract

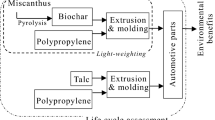

The principal aim of this study is to investigate the utilization feasibility of waste materials, i.e., recycled Polypropylene (PP), and fly ash in the formulation of auto parts which are commonly designed based on PP. The typical formulation of auto parts consists of PP, elastomer, filler, and compatibilizer. Various recycled PP/virgin PP ratios were considered as the matrix of the composites. It is found that the increasing concentration of recycled PP in the composite leads to a reduction in mechanical properties, particularly ductility and impact strength. However, due to a lower viscosity at the presence of recycled PP, better dispersion of filler particles, observed by SEM analysis, leading to the improvement of tensile strength. Besides, the employment of recycled material lowers the percentage of crystallinity and melting temperature. It is deduced that the deployment of 20/80 to 40/60 ratios of recycled PP/virgin PP in the composites reasonably meets the requirements for auto parts with advantages in the environmental and economic aspects. Compared to the composites filled with talc, the ductility of fly ash-filled composites is higher. The simultaneous utilization of talc and fly ash as a hybrid system brings about higher ductility, but lowers impact strength compared to talc-filled samples. Using recycled PP mixed with fly ash provides advantages in cost reduction and sustainable and environment-friendly production.

Similar content being viewed by others

References

Wu J-H, Chen C-W, Wu Y-T et al (2015) Mechanical properties, morphology, and crystallization behavior of polypropylene/elastomer/talc composites. Polym Compos 36:69–77. https://doi.org/10.1002/pc.22914

Rasana N, Jayanarayanan K, Deeraj BDS, Joseph K (2019) The thermal degradation and dynamic mechanical properties modeling of MWCNT/glass fiber multiscale filler reinforced polypropylene composites. Compos Sci Technol 169:249–259. https://doi.org/10.1016/j.compscitech.2018.11.027

Roh JU, Ma SW, Lee W, Il et al (2013) Electrical and mechanical properties of graphite/maleic anhydride grafted polypropylene nanocomposites. Compos Part B Eng 45:1548–1553. https://doi.org/10.1016/j.compositesb.2012.09.062

Erbas Kiziltas E, Duguay AJ, Kiziltas A et al (2018) Rheological and thermal properties of exfoliated graphite nanoplatelets-filled impact modified polypropylene nanocomposites. Polym Compos 39:E1512–E1519. https://doi.org/10.1002/pc.24400

Huang P, Wu M, Pang Y et al (2019) Ultrastrong, flexible and lightweight anisotropic polypropylene foams with superior flame retardancy. Compos Part A Appl Sci Manuf 116:180–186. https://doi.org/10.1016/j.compositesa.2018.10.027

Ajorloo M, Fasihi M, Khoramishad H (2020) The role of nanofiller size and polymer chain configuration on the properties of polypropylene/graphite nanoplates composites. J Taiwan Inst Chem Eng 108:82–91. https://doi.org/10.1016/j.jtice.2019.12.010

Moreno DDP, de Camargo RV, dos Santos Luiz D et al (2020) Composites of recycled polypropylene from cotton swab waste with pyrolyzed rice husk. J Polym Environ. https://doi.org/10.1007/s10924-020-01883-9

Aurrekoetxea J, Sarrionandia MA, Urrutibeascoa I, Maspoch ML (2001) Fracture behaviour of virgin and recycled isotactic polypropylene. J Mater Sci 36:5073–5078. https://doi.org/10.1023/A:1012460804698

Almaaded MA, Madi NK, Hodzic A, Soutis C (2014) Influence of additives on recycled polymer blends. J Therm Anal Calorim 115:811–821. https://doi.org/10.1007/s10973-013-3224-y

Bajracharya RM, Manalo AC, Karunasena W, Lau K (2016) Characterisation of recycled mixed plastic solid wastes: coupon and full-scale investigation. Waste Manage 48:72–80. https://doi.org/10.1016/j.wasman.2015.11.017

Ghodrat M, Abascall Alonso J, Hagare D et al (2019) Economic feasibility of energy recovery from waste plastic using pyrolysis technology: an Australian perspective. Int J Environ Sci Technol 16:3721–3734. https://doi.org/10.1007/s13762-019-02293-8

Zare Y (2013) Recent progress on preparation and properties of nanocomposites from recycled polymers: a review. Waste Manage 33:598–604. https://doi.org/10.1016/j.wasman.2012.07.031

Kazemi Y, Ramezani Kakroodi A, Rodrigue D (2015) Compatibilization efficiency in post-consumer recycled polyethylene/polypropylene blends: effect of contamination. Polym Eng Sci 55:2368–2376. https://doi.org/10.1002/pen.24125

da Costa HM, Ramos VD, de Oliveira MG (2007) Degradation of polypropylene (PP) during multiple extrusions: thermal analysis, mechanical properties and analysis of variance. Polym Test 26:676–684. https://doi.org/10.1016/j.polymertesting.2007.04.003

Strömberg E, Karlssom S (2009) The design of a test protocol to model the degradation of polyolefirts during eecycling and service life. J Appl Polym Sci 112:1835–1844. https://doi.org/10.1002/app.29724

Aurrekoetxea J, Sarrionandia MA, Urrutibeascoa I, Maspoch ML (2001) Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J Mater Sci 36:2607–2613. https://doi.org/10.1023/A:1017983907260

Bahlouli N, Pessey D, Raveyre C et al (2012) Recycling effects on the rheological and thermomechanical properties of polypropylene-based composites. Mater Des 33:451–458. https://doi.org/10.1016/j.matdes.2011.04.049

Kuram E, Sahin ZM, Ozcelik B et al (2014) Recyclability of polyethylene/polypropylene binary blends and enhancement of their mechanical properties by reinforcement with glass fiber. Polym Plast Technol Eng 53:1035–1046. https://doi.org/10.1080/03602559.2014.886066

Ghahri S, Najafi SK, Mohebby B, Tajvidi M (2012) Impact strength improvement of wood flour-recycled polypropylene composites. J Appl Polym Sci 124:1074–1080. https://doi.org/10.1002/app.34015

Incarnato L, Scarfato P, Acierno D et al (2003) Influence of recycling and contamination on structure and transport properties of polypropylene. J Appl Polym Sci 89:1768–1778. https://doi.org/10.1002/app.12168

Elloumi A, Pimbert S, Bourmaud A, Bradai C (2010) Thermomechanical properties of virgin and recycled polypropylene impact copolymer/CaCO3 nanocomposites. Polym Eng Sci 50:1904–1913. https://doi.org/10.1002/pen.21716

Wang K, Bahlouli N, Addiego F et al (2013) Effect of talc content on the degradation of re-extruded polypropylene/talc composites. Polym Degrad Stab 98:1275–1286. https://doi.org/10.1016/j.polymdegradstab.2013.04.006

Izzati Zulkifli N, Samat N, Anuar H, Zainuddin N (2015) Mechanical properties and failure modes of recycled polypropylene/microcrystalline cellulose composites. Mater Des 69:114–123. https://doi.org/10.1016/j.matdes.2014.12.053

Yao ZT, Chen T, Li HY et al (2013) Mechanical and thermal properties of polypropylene (PP) composites filled with modified shell waste. J Hazard Mater 262:212–217. https://doi.org/10.1016/j.jhazmat.2013.08.062

Wang K, Addiego F, Bahlouli N et al (2014) Impact response of recycled polypropylene-based composites under a wide range of temperature: effect of filler content and recycling. Compos Sci Technol 95:89–99. https://doi.org/10.1016/j.compscitech.2014.02.014

Borovanska I, Krastev R, Benavente R et al (2014) Ageing effect on morphology, thermal and mechanical properties of impact modified LDPE/PP blends from virgin and recycled materials. J Elastomers Plast 46:427–447. https://doi.org/10.1177/0095244312469959

Brachet P, Høydal LT, Hinrichsen EL, Melum F (2008) Modification of mechanical properties of recycled polypropylene from post-consumer containers. Waste Manage 28:2456–2464. https://doi.org/10.1016/j.wasman.2007.10.021

Jiménez A, Torre L, Kenny JM (2003) Processing and properties of recycled polypropylene modified with elastomers. Plast Rubber Compos 32:357–367. https://doi.org/10.1179/146580103225004126

Al-Mulla A, Shaban H (2014) Study on compatibility of recycled polypropylene/high-density polyethylene blends using rheology. Polym Bull 71:2335–2352. https://doi.org/10.1007/s00289-014-1191-5

Zulkifli NI, Noorasikin S (2013) Mechanical properties of green recycled polypropylene composites: effect of maleic anhydride grafted polypropylene (MAPP) coupling agent. In: Dzaraini K, Siti NS (eds) Advanced materials research. Trans Tech Publications Ltd, Baech, pp 187–191

Al-Mulla A, Alfadhel K, Qambar G, Shaban H (2013) Rheological study of recycled polypropylene-starch blends. Polym Bull 70:2599–2618. https://doi.org/10.1007/s00289-013-0977-1

Das K, Ray D, Adhikary K et al (2010) Development of recycled polypropylene matrix composites reinforced with fly ash. J Reinf Plast Compos 29:510–517. https://doi.org/10.1177/0731684408099415

Khademi F, Ma Y, Ayranci C et al (2016) Effects of recycling on the mechanical behavior of polypropylene at room temperature through statistical analysis method. Polym Eng Sci 56:1283–1290. https://doi.org/10.1002/pen.24363

Rizvi SH, Masood SH, Sbarski I (2007) An investigation of mechanical, thermal and creep behaviour of recycled industrial polyolefins. Prog Rubber Plast Recycl Technol 23:97–110. https://doi.org/10.1177/147776060702300202

Bertin S, Robin JJ (2002) Study and characterization of virgin and recycled LDPE/PP blends. Eur Polym J 38:2255–2264. https://doi.org/10.1016/S0014-3057(02)00111-8

Satapathy S, Kothapalli RVS (2018) Mechanical, dynamic mechanical and thermal properties of banana fiber/recycled high density polyethylene biocomposites filled with flyash cenospheres. J Polym Environ 26:200–213. https://doi.org/10.1007/s10924-017-0938-0

Ajorloo M, Ghodrat M, Moghbeli MR, Kang WH (2020) A statistical approach to investigate the effects of multicomponent fractions on the mechanical properties of PP/PPMA/Talc/POE composites. J Polym Res 27:1–18. https://doi.org/10.1007/s10965-020-2042-8

Park S, He S, Wang J et al (2016) Graphene-polyethylene nanocomposites: effect of graphene functionalization. Polymer 104:1–9. https://doi.org/10.1016/j.polymer.2016.09.058

Duan J, Dou Q (2013) Investigation on β-polypropylene/PP-g-MAH/surface treated talc composites. J Appl Polym Sci 130:206–221. https://doi.org/10.1002/app.39178

Sheril RV, Mariatti M, Samayamutthirian P (2014) Single and hybrid mineral fillers (talc/silica and talc/calcium carbonate)-filled polypropylene composites: effects of filler loading and ratios. J Vinyl Addit Technol 20:160–167. https://doi.org/10.1002/vnl.21347

Mehrjerdi AK, Mengistu BA, Åkesson D, Skrifvars M (2014) Effects of a titanate coupling agent on the mechanical and thermo-physical properties of talc-reinforced polyethylene compounds. J Appl Polym Sci. https://doi.org/10.1002/app.40449

Goh CK, Valavan SE, Low TK, Tang LH (2016) Effects of different surface modification and contents on municipal solid waste incineration fly ash/epoxy composites. Waste Manage 58:309–315. https://doi.org/10.1016/j.wasman.2016.05.027

Chand N, Sharma P, Fahim M (2010) Correlation of mechanical and tribological properties of organosilane modified cenosphere filled high density polyethylene. Mater Sci Eng A 527:5873–5878. https://doi.org/10.1016/j.msea.2010.06.022

Nguyen LT, Vu CM, Phuc BT, Tung NH (2019) Simultaneous effects of silanized coal fly ash and nano/micro glass fiber on fracture toughness and mechanical properties of carbon fiber-reinforced vinyl ester resin composites. Polym Eng Sci 59:584–591. https://doi.org/10.1002/pen.24973

Deepthi MV, Sharma M, Sailaja RRN et al (2010) Mechanical and thermal characteristics of high density polyethylene-fly ash Cenospheres composites. Mater Des 31:2051–2060. https://doi.org/10.1016/j.matdes.2009.10.014

El-Midany AA, Ibrahim SS (2010) The effect of mineral surface nature on the mechanical properties of mineral-filled polypropylene composites. Polym Bull 64:387–399. https://doi.org/10.1007/s00289-009-0209-x

Liu Y, Kontopoulou M (2006) The structure and physical properties of polypropylene and thermoplastic olefin nanocomposites containing nanosilica. Polymer 47:7731–7739. https://doi.org/10.1016/j.polymer.2006.09.014

Bagheri-Kazemabad S, Fox D, Chen Y et al (2012) Morphology, rheology and mechanical properties of polypropylene/ethylene-octene copolymer/clay nanocomposites: Effects of the compatibilizer. Compos Sci Technol 72:1697–1704. https://doi.org/10.1016/j.compscitech.2012.06.007

Hu X, Geng C, Yang G et al (2015) Synergetic effects of a matrix crystalline structure and chain mobility on the low temperature toughness of polypropylene/ethylene-octene copolymer blends. RSC Adv 5:54488–54496. https://doi.org/10.1039/c5ra09685e

Zhang L, Li C, Huang R (2005) Toughness mechanism of polypropylene/elastomer/ filler composites. J Polym Sci Part B Polym Phys 43:1113–1123. https://doi.org/10.1002/polb.20395

Wong KWY, Truss RW (1994) Effect of flyash content and coupling agent on the mechanical properties of flyash-filled polypropylene. Compos Sci Technol 52:361–368. https://doi.org/10.1016/0266-3538(94)90170-8

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ajorloo, M., Ghodrat, M. & Kang, WH. Incorporation of Recycled Polypropylene and Fly Ash in Polypropylene-Based Composites for Automotive Applications. J Polym Environ 29, 1298–1309 (2021). https://doi.org/10.1007/s10924-020-01961-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01961-y