Abstract

Waste management has become a major concern due to the extensive use of commodity polymers. Nowadays, one of the most widely used commodity polymers is nonwoven PP. The extensive utilization of polypropylene produces a large amount of waste, making their upcycling and recycling the biggest challenge. This research aims to develop an economical nanocomposite by upcycling nonwoven waste for utilization in the automotive and electronic sectors. A two-step melt blending technique was used to prepare polypropylene waste/silica nanocomposites. The nanocomposites formed were characterized by their morphological, mechanical, thermal, rheological, chemical, and electrical properties. From the results, it was concluded that the optimum mechanical, thermal, and chemical resistance properties were achieved for PP-01 formulation showing a 9.95% increase in heat deflection temperature, a 27.57% decrease in the rate of burning, a 5.4% increase in shore D hardness, 26.09% increase in flexural strength, 11.6% increase in melt flow index, and 66.25% increase in solvent resistance as compared to waste polypropylene. At the same time, the best electrical results were obtained at 0.5 wt.% with a 5.36% increase in the breakdown strength. The resistance value increases from 4.67 × 1012 Ω to 2 × 1013 Ω. The overall research shows that optimum mechanical and thermal properties were achieved at 1 wt.% so that the PP-01 formulation can be used effectively for automotive applications. In contrast, maximum electrical resistance was achieved at the PP-0.5 formulation so that this formulation could be effectively used for electrical insulation applications.

Similar content being viewed by others

References

Yalcin I, Sadikoglu TG, Berkalp OB et al (2013) Utilization of various non-woven waste forms as reinforcement in polymeric composites. Text Res J 83:1551–1562

EDANA (2020) Nonwoven statistics 2020. https://www.edana.org/docs/default-source/press-corner/nonwovens-statistics-2019.pdf?sfvrsn=dbad6d4c_6. Accessed 24 June 2023

EDANA (2021) The voice of Nonwoven. https://www.edana.org/about-us/news/2020-nonwovens-market-insights#:~:text=According%20to%20figures%20collected%20and,turnover%20of%20%E2%82%AC9%C555%20million. Accessed 24 June 2023

Qayyum Gill Y, Khurshid M, Mehmood U, et al (2022) Upscale recycling of nonwoven polypropylene waste using a novel blending method. J Appl Polymer Sci 139(39)

Lou C-W, Lin J-H, Su K-H (2005) Recycling polyester and polypropylene nonwoven selvages to produce functional sound absorption composites. Text Res J 75:390–394

Quintana-Gallardo A, Del Rey R, González-Conca S et al (2023) The Environmental Impacts of Disposable Nonwoven Fabrics during the COVID-19 Pandemic: Case Study on the Francesc de Borja Hospital. Polymers 15:1130

Overcash M (2012) A comparison of reusable and disposable perioperative textiles: sustainability state-of-the-art 2012. Anesth Analg 114:1055–1066

WHO Coronavirus (COVID-19) Dashboard. In: World Health Organization. https://covid19.who.int/. Accessed 24 June 2023

Pandit P, Maity S, Singha K et al (2021) Potential biodegradable face mask to counter environmental impact of Covid-19. Clean Eng Technol 4:100218

Ramasamy R, Subramanian RB (2023) Recycling of disposable single-use face masks to mitigate microfiber pollution. Environ Sci Pollut Res 30:50938–50951

Prata JC, Silva AL, Walker TR et al (2020) COVID-19 pandemic repercussions on the use and management of plastics. Environ Sci Technol 54:7760–7765

Silva ALP, Prata JC, Duarte AC et al (2021) An urgent call to think globally and act locally on landfill disposable plastics under and after covid-19 pandemic: pollution prevention and technological (Bio) remediation solutions. Chem Eng J 426:131201

Lou CW, Lin C-M, Hsing W-H et al (2011) Manufacturing techniques and electrical properties of conductive fabrics with recycled polypropylene nonwoven selvage. Text Res J 81:1331–1343

Echeverria CA, Pahlevani F, Sahajwalla V (2020) Valorisation of discarded nonwoven polypropylene as potential matrix-phase for thermoplastic-lignocellulose hybrid material engineered for building applications. J Clean Prod 258:120730

Nafady A, Albaqami MD and Alotaibi AM (2023) Recycled polypropylene waste as abundant source for antimicrobial, superhydrophobic and electroconductive nonwoven fabrics comprising polyaniline/silver nanoparticles. J Inorg Organ Polymers Mater 1–11

Singsatit P, Pimpan V (2009) Recycling of medical gown nonwoven fabric manufacturing waste as a filler for high density polyethylene. J Metals Mater Min 19

Battegazzore D, Cravero F, Frache A (2020) Is it possible to mechanical recycle the materials of the disposable filtering masks? Polymers 12:2726

Lin JH, Lin CM, Kuo CY, et al (2010) Manufacture technology of novel reinforcing composite geotextile made of recycled nonwoven selvages. In: Advanced materials research. Trans Tech Publ, pp 137–140

Kansal H (2016) Experimental investigation of properties of polypropylene and non-woven spunbond fabric. IOSR J Polymer Text Eng 3:8–14

Betiha MA, Moustafa YM, Mansour AS et al (2020) Nontoxic polyvinylpyrrolidone-propylmethacrylate-silica nanocomposite for efficient adsorption of lead, copper, and nickel cations from contaminated wastewater. J Mol Liquids 314:113656

Cobley AJ, Mason TJ, Alarjah M et al (2011) The effect of ultrasound on the gold plating of silica nanoparticles for use in composite solders. Ultrason Sonochem 18(1):37–41

Danhua Xie, Yulong Jiang, Renjie Xu, et al (2023) Preparation of ethanol-gels as hand sanitizers formed from chitosan and silica nanoparticles. J Mol Liquids 122276

Shirshahi V, Soltani M (2015) Solid silica nanoparticles: applications in molecular imaging. Contrast Media Mol Imaging 10:1–17

Amin M (2013) Methods for preparation of nano-composites for outdoor insulation applications. Rev Adv Mater Sci 34:173–184

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng R Rep 28:1–63

Cho J, Paul D (2001) Nylon 6 nanocomposites by melt compounding. Polymer 42:1083–1094

LeBaron PC, Wang Z, Pinnavaia TJ (1999) Polymer-layered silicate nanocomposites: an overview. Appl Clay Sci 15:11–29

Tung J, Gupta RK, Simon GP et al (2005) Rheological and mechanical comparative study of in situ polymerized and melt-blended nylon 6 nanocomposites. Polymer 46:10405–10418

Madaleno L, Schjødt-Thomsen J, Pinto JC (2010) Morphology, thermal and mechanical properties of PVC/MMT nanocomposites prepared by solution blending and solution blending+ melt compounding. Compos Sci Technol 70:804–814

Dlamini D, Mishra S, Mishra A et al (2011) Comparative studies of the morphological and thermal properties of clay/polymer nanocomposites synthesized via melt blending and modified solution blending methods. J Compos Mater 45:2211–2216

Lim KS, Mariatti M, Kamarol M et al (2019) Properties of nanofillers/crosslinked polyethylene composites for cable insulation. J Vinyl Add Tech 25:E147–E154

Hirschl C, Biebl-Rydlo M, DeBiasio M et al (2013) Determining the degree of crosslinking of ethylene vinyl acetate photovoltaic module encapsulants—A comparative study. Sol Energy Mater Sol Cells 116:203–218

Rashid IA, Tariq A, Shakir HF et al (2022) Electrically conductive epoxy/polyaniline composite fabrication and characterization for electronic applications. J Reinf Plast Compos 41:34–45

Ossila. In: Four-probe method: Sheet resistance formula. https://www.ossila.com/pages/sheet-resistance-theory. Accessed 24 June 2023

Fang J, Zhang L, Sutton D et al (2012) Needleless melt-electrospinning of polypropylene nanofibres. J Nanomater 2012:1–9

Jung S, Lee S, Dou X et al (2021) Valorization of disposable COVID-19 mask through the thermo-chemical process. Chem Eng J 405:126658

Ajorloo M, Ghodrat M, Kang W-H (2021) Incorporation of recycled polypropylene and fly ash in polypropylene-based composites for automotive applications. J Polym Environ 29:1298–1309

Tan X, Xu Y, Cai N et al (2009) Polypropylene/silica nanocomposites prepared by in-situ melt ultrasonication. Polym Compos 30:835–840

Zoukrami F, Haddaoui N, Sclavons M et al (2018) Rheological properties and thermal stability of compatibilized polypropylene/untreated silica composites prepared by water injection extrusion process. Polym Bull 75:5551–5566

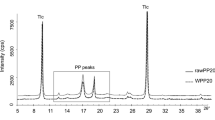

Oh T, Choi CK (2010) Comparison between Si–O–C thin films fabricated by using plasma enhance chemical vapor deposition and SiO2 thin films by using Fourier transform infrared spectroscopy. J Korean Phys Soc 56(4):1150–1155

Al-Shawi SA, Alansari LS, Diwan AA, et al (2021) Enhancement tensile strength, creep resistance and hardness of an epoxy resin by adding SiO2 nanoparticles. In: IOP Conference Series: Materials Science and Engineering 2021. IOP Publishing, p 012142

Luyt A, Messori M, Fabbri P et al (2011) Polycarbonate reinforced with silica nanoparticles. Polym Bull 66:991–1004

Ai NA, Hussein S, Jawad M et al (2015) Effect of Al2O3 and SiO2 nanopartical on wear, hardness and impact behavior of epoxy composites. Chem Mater Res 7:34–40

Gustin J, Freeman B, Stone J et al (2005) Low-velocity impact of nanocomposite and polymer plates. J Appl Polym Sci 96:2309–2315

Sui Y, Cui Y, Cong C, et al (2022) Rheological and mechanical properties of automobile polypropylene/silica (PP/SiO2) nanocomposites. In: Journal of Physics: Conference Series. IOP Publishing, p 012004

Yang F, Ou Y, Yu Z (1998) Polyamide 6/silica nanocomposites prepared by in situ polymerization. J Appl Polym Sci 69:355–361

Sapiai N, Jumahat A, Jawaid M et al (2020) Tensile and flexural properties of silica nanoparticles modified unidirectional kenaf and hybrid glass/kenaf epoxy composites. Polymers 12:2733

Zou H, Wu S, Shen J (2008) Polymer/silica nanocomposites: preparation, characterization, properties, and applications. Chem Rev 108:3893–3957

Motahari S, Motlagh GH, Moharramzadeh A (2015) Thermal and flammability properties of polypropylene/silica aerogel composites. J Macromol Sci B 54:1081–1091

Jakubowska P, Osińska-Broniarz M, Martyla A et al (2016) Thermal properties of PP-SiO2 composites filled with Stöber silica. Compos Theory Pract 6:161–166

Gill YQ, Ehsan H, Mehmood U et al (2022) A novel two-step melt blending method to prepare nano-silanized-silica reinforced crosslinked polyethylene (XLPE) nanocomposites. Polym Bull 79:10077–10093

Srisawat N, Nithitanakul M, Srikulkit K (2009) Characterizations of fibers produced from polypropylene/silica composite. J Metals Mater Miner 19

Sun D, Zhang R, Liu Z et al (2005) Polypropylene/silica nanocomposites prepared by in-situ sol−gel reaction with the aid of CO2. Macromolecules 38:5617–5624

Wong A-Y (2003) Heat deflection characteristics of polypropylene and polypropylene/polyethylene binary systems. Compos B Eng 34:199–208

Dorigato A, Pegoretti A (2014) Reprocessing effects on polypropylene/silica nanocomposites. J Appl Polymer Sci 131

Perez-Guerrero A, Lisperguer J, Orellana F (2011) Influence of silica nanoparticles on the thermomechanical properties of recycled polystyrene. J Chil Chem Soc 56:907–910

Hwang S-s, Hsu pp (2013) Effects of silica particle size on the structure and properties of polypropylene/silica composites foams. J Ind Eng Chem 19:1377–1383

Kumar A, Patham B, Mohanty S et al (2020) Polypropylene–nano-silica nanocomposite foams: mechanisms underlying foamability, and foam microstructure, crystallinity and mechanical properties. Polym Int 69:373–386

Ahmed T, Mamat O (2011) The development and properties of polypropylene-silica sand nanoparticles composites. In: 2011 IEEE Colloquium on Humanities, Science and Engineering. IEEE, pp 172–177

Hadi NJ and Mohamed DJ (2017) Study the relation between flow, thermal and mechanical properties of waste polypropylene filled silica nanoparticles. In: Key engineering materials. Trans Tech Publ, pp 28–38

Abdul Razak NI, Yusoff NISM, Ahmad MH et al (2023) Dielectric, mechanical, and thermal properties of crosslinked polyethylene nanocomposite with hybrid nanofillers. Polymers 15:1702

Rytöluoto I, Ritamäki M, Lahti K, et al (2018) Compounding, structure and dielectric properties of silica-BOPP nanocomposite films. In: 2018 IEEE 2nd International Conference on Dielectrics (ICD) 1–5 July 2018, pp 1–4

Funding

Funding for this study was received from the Pakistan Science Foundation: PSF-CRP, Grant/Award Number: PSF/CRP/3/P-UET/PPE/50.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gill, Y.Q., Jabeen, F., Saeed, F. et al. Development of commercially viable and high-performance upcycled plastic waste nanocomposites for automotive and electrical industry. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05239-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05239-4