Abstract

Cracks in polymers can be healed by endowing materials with self-healing performance. Cracks in epoxy resins containing thermo-reversible Diels–Alder bonds (EP-DA) can be self-healed via different heat treatments. However, EP-DA exhibits the disadvantages of brittleness and poor impact resistance yet as that existed in the common epoxy resins, and which limits the application of thermo-reversible self-healing epoxy resins. Herein, thermoplastic polyurethane (TPU) was introduced into EP-DA for the purpose of reducing the brittleness and improving the impact resistance of EP-DA. Meanwhile, it was expected that the self-healing performance of EP-DA could not be affected evidently. Results showed that the impact resistance of EP-DA had been improved greatly as expected upon TPU modification. More importantly, instead of affecting the self-healing performance of EP-DA, the self-healing speed of EP-DA was accelerated evidently by the incorporation of TPU. On the other hand, the healing efficiency of EP-DA was also enhanced markedly. In fact, TPU-modified EP-DA was repaired by dual actions of thermo-reversible DA reaction and thermal movement of thermoplastic polymer chains. In addition, TPU-modified EP-DA could also be healed for many damage-repair cycles. Therefore, thermoplastic polyurethane played a triple role as toughening, accelerating and enhancing self-healing performance of thermo-reversible epoxy resins.

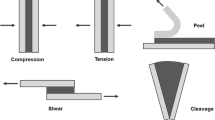

Graphic Abstract

Thermoplastic polyurethane (TPU) was introduced into thermo-reversible self-healing epoxy resins (EP-DA) successfully. As a result, the brittleness was reduced and the impact resistance of EP-DA was improved greatly. What’s more, instead of affecting the self-healing performance of EP-DA, the self-healing speed of EP-DA was accelerated evidently while the self-healing efficiency of EP-DA was enhanced markedly. Therefore, TPU played a triple role as toughening, accelerating and enhancing self-healing performance of thermo-reversible epoxy resins.

Similar content being viewed by others

References

Russell BK, Takeda S, Ward C et al (2019) React Funct Polym 144:104353

Kocaman S, Ahmetli G (2020) J Polym Environ 28:1190

Sarkar S, Kim B (2016) Polym Compos 39:636

Feng LB, Yu ZY, Bian YH et al (2017) Polymer 124:48

He ZL, Jiang S, An N (2019) J Mater Sci 54:8262

Feng LB, Bian YH, Chai CS et al (2020) J Polym Environ 28:647

Yang SW, Du XS, Du ZL et al (2020) Polymer 190:122219

An SY, Noh SM, Nam JH et al (2015) Macromol Rapid Commun 36:1255

Davis DA, Hamilton A, Yang JL et al (2009) Nature 459:68

Garcia-Jimeno S, Cano-Sarabia M, Mejias N et al (2015) J Mater Chem A 3:17966

Chen QM, Yu XW, Pei ZQ et al (2017) Chem Sci 8:724

Lu YX, Guan Z (2012) J Am Chem Soc 134:14226

Kim S, Jeon H, Shin S et al (2018) Adv Mater 30:1705145

Montarnal D, Tournilhac F, Hidalgo M et al (2009) J Am Chem Soc 131:7966

Thakur VK, Kessler MR et al (2015) Polymer 69:369

Shi Y, Wang M, Ma C et al (2015) Nano Lett 15:6276

Jo YY, Lee AS, Baek KY et al (2016) Polymer 108:58

Feng LB, Yu ZY, Bian YH et al (2018) Constr Build Mater 186:1212

Postiglione G, Turri S, Levi M (2015) Prog Org Coat 78:526

Duval A, Couture G, Caillol S et al (2017) ACS Sustain Chem Eng 5:1199

Henderson JR, Chesterman JP, Parvez M et al (2010) J Org Chem 75:988

Samaneh S, Morteza A, Bahram R (2019) J Ind Eng Chem 75:271

Ma SQ, Liu WQ, Hu CH (2010) Macromol Res 18:392

He S, Shi K, Bai J et al (2001) Polymer 42:9641

Bakar M, Duk R, Przybylek M et al (2009) J Reinf Plast Compos 28:2107

Gui D, Xue G, Hao J et al (2014) Polym Eng Sci 54:1704

Chen TH, Li HS, Gao Y et al (1998) J Appl Polym Sci 69:887

Bakar M, Kostrzewa M, Pawelec Z (2014) J Thermoplast Compos 27:620

Zhao HW, Feng LB, Shi XT et al (2018) Acta Polym Sin 3:395

Chen SB, Wang QH, Wang TM (2013) J Reinf Plast Compos 32:1136

Ho T, Wang C (2015) J Appl Polym Sci 74:1905

Scheltjens G, Diaz MM, Brancart J et al (2013) React Funct Polym 73:413

Grenier-Loustalot MJ, Cunha JD (1998) Eur Polym J 34(1998):95

Acknowledgements

This research is supported by National Natural Science Foundation of China (Grant No. 51463010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors claim there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, L., He, X., Zhang, Y. et al. Triple Roles of Thermoplastic Polyurethane in Toughening, Accelerating and Enhancing Self-healing Performance of Thermo-reversible Epoxy Resins. J Polym Environ 29, 829–836 (2021). https://doi.org/10.1007/s10924-020-01923-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01923-4