Abstract

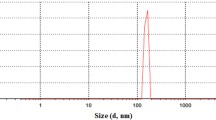

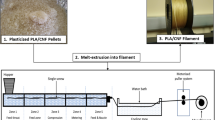

Unprecedented levels of production and consumption has led to solid waste accumulation in landfills and oceans. Two significant landfill constituents are textile waste and discarded plastic bottles. Since there is a finite amount of space available for landfill use, solutions that reuse these post-consumer products are imperative. The work presented here is a methodology for producing natural fiber-reinforced polymer composites (NFRPCs) from pseudo-raw materials. Post-consumer textile waste and polyethylene terephthalate (PET) water bottles were made compatible by way of surface modifications. Melt compounding was used to form a monofilament feedstock for extrusion-based 3D printing platforms. Hydrolysis and functionalization of cellulose fibers from white denim cloth was performed. It was found that adding recycled textile fibers to the recycled PET matrix had a toughening effect. Materials characterization involving dynamic mechanical analysis, attenuated total reflectance, impact testing, melt flow index, and scanning electron microscopy were carried out to verify the efficacy of the functionalization process and to ascertain the robustness of the filler/matrix interface. The outcome is a demonstration of a feasible method for the repurposing of waste products for 3D printing applications.

Similar content being viewed by others

References

Kaiser J (2010) The dirt on ocean garbage patches. Science 328:1506. https://doi.org/10.1126/science.328.5985.1506

Blumberg L, Gottlieb R (1989) War on waste: can america win its battle with garbage? Louis Blumberg Robert Gottlieb. Island Press, Washington

Guiltinan J (2009) Creative destruction and destructive creations: environmental ethics and planned obsolescence. J Bus Ethics 89:19–28. https://doi.org/10.1007/s10551-008-9907-9

Packard V (1959) The status seekers an exploration of class behavior in America. Longmans, New York

Aladeojebi TK (2013) Planned obsolescence. Int J Sci Eng Res 6:1504–1508

Mason R (1985) Ethics and the supply of status goods. J Bus Ethics 4:457–464. https://doi.org/10.1007/BF00382607

US EPA (2015) US EPA, National overview: facts and figures on materials, wastes and recycling

Jambeck JR, Geyer R, Wilcox C et al (2015) Marine pollution. Plastic waste inputs from land into the ocean. Science 347:768–71. https://doi.org/10.1126/science.1260352

Thompson RC (2006) Plastic debris in the marine environment: consequences and solutions. In: Marine Nature Conservation in Europe 2006. Stralsund, Germany

Fries E, Dekiff JH, Willmeyer J et al (2013) Identification of polymer types and additives in marine microplastic particles using pyrolysis-GC/MS and scanning electron microscopy. Environ Sci Process Impacts 15:1949. https://doi.org/10.1039/c3em00214d

Liboiron M (2016) Redefining pollution and action: the matter of plastics. J Mater Cult 21:87–110. https://doi.org/10.1177/1359183515622966

Koch K, Domina T (1997) The effects of environmental attitude and fashion opinion leadership on textile recycling in the US. J Consum Stud Home Econ 21:1–17. https://doi.org/10.1111/j.1470-6431.1997.tb00265.x

Domina T, Koch K (1997) The textile waste lifecycle. Cloth Text Res J 15:96–102. https://doi.org/10.1177/0887302X9701500204

Claudio L (2007) Waste couture: environmental impact of the clothing industry. Environ Health Perspect. https://doi.org/10.1289/ehp.115-a449

Lewis T (2015) Apparel disposal and reuse. Sustain Appar. https://doi.org/10.1016/B978-1-78242-339-3.00010-8

Binotto C, Payne A (2017) The poetics of waste: contemporary fashion practice in the context of wastefulness. Fash Pract 9:5–29. https://doi.org/10.1080/17569370.2016.1226604

Norris L (2012) Trade and transformations of secondhand clothing: introduction. Textile 10:128–143. https://doi.org/10.2752/175183512X13315695424473

Carrete IA (2019) Development and characterization of polyethylene terephalate (PET)-cotton natural fiber-reinforced composites from waste materials. The University of Texas at El Paso, El Paso

Miao C, Hamad WY (2013) Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose 20:2221–2262

Zander NE, Gillan M, Burckhard Z, Gardea F (2019) Recycled polypropylene blends as novel 3D printing materials. Addit Manuf 25:122–130. https://doi.org/10.1016/j.addma.2018.11.009

Zander NE, Gillan M, Lambeth RH (2018) Recycled polyethylene terephthalate as a new FFF feedstock material. Addit Manuf 21:174–182. https://doi.org/10.1016/j.addma.2018.03.007

Torrado AR, Roberson DA (2016) Failure analysis and anisotropy evaluation of 3D-printed tensile test specimens of different geometries and print raster patterns. J Fail Anal Prev 16:154–164. https://doi.org/10.1007/s11668-016-0067-4

Milosevic M, Stoff D (2017) Characterizing the mechanical properties of fused deposition modelling natural fiber recycled polypropylene composites. J Compos Sci 1:7. https://doi.org/10.3390/jcs1010007

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626. https://doi.org/10.1021/bm0493685

Dong XM, Revol J-F, Gray DG (1998) Effect of microcrystallite preparation conditions on the formation of colloid crystals of cellulose. Cellulose 5:19–32. https://doi.org/10.1023/A:1009260511939

Medeiros ES, Mattoso LHC, Bernardes-Filho R et al (2008) Self-assembled films of cellulose nanofibrils and poly(o-ethoxyaniline). Colloid Polym Sci 286:1265–1272. https://doi.org/10.1007/s00396-008-1887-x

Araújo RS, Ferreira LC, Rezende CC et al (2018) Poly(lactic acid)/cellulose composites obtained from modified cotton fibers by successive acid hydrolysis. J Polym Environ 26:3149–3158. https://doi.org/10.1007/s10924-018-1198-3

Roberson David, Shemelya Corey M, MacDonald Eric, Wicker Ryan (2015) Expanding the applicability of FDM-type technologies through materials development. Rapid Prototype J 21:137–143. https://doi.org/10.1108/RPJ-12-2014-0165

Roberson DA, Torrado Perez AR, Shemelya CM et al (2015) Comparison of stress concentrator fabrication for 3D printed polymeric izod impact test specimens. Addit Manuf 7:1–11. https://doi.org/10.1016/j.addma.2015.05.002

D20 Committee Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

Geng Y, Laborie M-PG (2010) The impact of silane chemistry conditions on the properties of wood plastic composites with low density polyethylene and high wood content. Polym Compos 31:897–905. https://doi.org/10.1002/pc.20873

Najafi SK, Mostafazadeh-Marznaki M, Chaharmahali M, Tajvidi M (2009) Effect of thermomechanical degradation of polypropylene on mechanical properties of wood-polypropylene composites. J Compos Mater 43:2543–2554. https://doi.org/10.1177/0021998309345349

Steward EL, Bradley M (1991) The influence of extrusion parameters on the degradation of polypropylene. J Plast Film Sheeting 7:355–374. https://doi.org/10.1177/875608799100700407

Carrete IA, Bermudez D, Aguirre C et al (2019) Failure analysis of additively manufactured polyester test specimens exposed to various liquid media. J Fail Anal Prev. https://doi.org/10.1007/s11668-019-00614-0

Menard KP, Bilyeu BW (2008) Dynamic mechanical analysis of polymers and rubbers. In: Encyclopedia of analytical chemistry. Wiley, Chichester

Shemelya CM, Rivera A, Perez AT et al (2015) Mechanical, electromagnetic, and X-ray shielding characterization of a 3D printable tungsten-polycarbonate polymer matrix composite for space-based applications. J Electron Mater 44:2598–2607. https://doi.org/10.1007/s11664-015-3687-7

Schnittker K, Arrieta E, Jimenez X et al (2018) Integrating digital image correlation in mechanical testing for the materials characterization of big area additive manufacturing feedstock. Addit Manuf. https://doi.org/10.1016/j.addma.2018.12.016

Das K, Ray D, Bandyopadhyay NR et al (2009) A study of the mechanical, thermal and morphological properties of microcrystalline cellulose particles prepared from cotton slivers using different acid concentrations. Cellulose 16:783–793. https://doi.org/10.1007/s10570-009-9280-6

Haafiz MKM, Hassan A, Zakaria Z et al (2013) Properties of polylactic acid composites reinforced with oil palm biomass microcrystalline cellulose. Carbohydr Polym 98:139–145. https://doi.org/10.1016/J.CARBPOL.2013.05.069

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33. https://doi.org/10.1007/s10924-006-0042-3

Acknowledgements

The work demonstrated in this article was carried out in the Polymer Extrusion Lab in the Department of Metallurgical, Materials and Biomedical Engineering at The University of Texas at El Paso. The authors thank Ing. Gustavo Cordova of Cordova Distributing, LLC for his donation of drinking water bottles.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Carrete, I.A., Quiñonez, P.A., Bermudez, D. et al. Incorporating Textile-Derived Cellulose Fibers for the Strengthening of Recycled Polyethylene Terephthalate for 3D Printing Feedstock Materials. J Polym Environ 29, 662–671 (2021). https://doi.org/10.1007/s10924-020-01900-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01900-x