Abstract

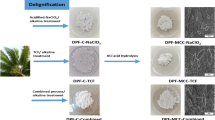

Esparto grass, known as alfa, is a renewable biomass widely distributed in southern and western Mediterranean basin. The present work focused on the isolation of pure cellulose from alfa stems, via different approaches, i.e., acidified sodium chlorite (NaClO2), totally chlorine free (TCF) or their combination, followed by the preparation of microcrystalline cellulose (MCC) using acid hydrolysis method. The obtained samples were characterized using infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscopy (SEM), thermogravimetry (TGA) and differential scanning calorimeter (DSC). The FTIR spectroscopy exhibited the removal of lignin and hemicellulose after the delignification and alkaline treatments. The XRD data showed that all of the MCCs have higher crystallinity indexes (Alfa-MCC 73–82%) and belong to cellulose I type. From SEM images, it is clear that the different MCC particles presented rough surface and micro-sized particles. The DSC/TGA analyses revealed that MCC samples present better thermal stability than their respective cellulose ones, with higher temperature of decomposition (more than 350 °C). Moreover, the use of a combined process yields to MCC with higher crystallinity and better thermal stability. Consequently, based on these findings, the delignification with combined method can be considered as a promising approach to extract MCC from alfa fibers with outstanding features.

Similar content being viewed by others

References

Trache D (2017) Microcrystalline cellulose and related polymer composites: synthesis, characterization and properties. In: Thakur VK, Thakur MK, Kessle MR (eds) Handbook of composites from renewable materials, structure and chemistry. Wiley, New York, pp 61–92

Tarchoun AF, Trache D, Klapötke TM (2019) Microcrystalline cellulose from Posidonia oceanica brown algae: Extraction and characterization. Int J Biol Macromol 138:837–845

Khalil HA, Lai TK, Tye YY, Paridah M, Fazita MN, Azniwati A et al (2018) Preparation and Characterization of Microcrystalline Cellulose from Sacred Bali Bamboo as Reinforcing Filler in Seaweed-based Composite Film. Fibers Polym 19(2):423–434

Owolabi AF, Haafiz MM, Hossain MS, Hussin MH, Fazita MN (2017) Influence of alkaline hydrogen peroxide pre-hydrolysis on the isolation of microcrystalline cellulose from oil palm fronds. Int J Biol Macromol 95:1228–1234

Yuliasmi S, Pardede T, Syahputra H, editors. Comparison of microcrystalline characterization results from oil palm midrib alpha cellulose using different delignization method. IOP Conference Series: Materials Science and Engineering; 2017: IOP Publishing

Lamaming J, Chew SC, Hashim R, Sulaiman O, Sugimoto T (2017) Extraction of microcrystalline cellulose from oil palm trunk. J Jpn Inst Energy 96(11):513–518

Thoorens G, Krier F, Leclercq B, Carlin B, Evrard BJIJoP, (2014) Microcrystalline cellulose, a direct compression binder in a quality by design environment—A review. Int J Pharm 473(1–2):64–72

Trache D, Hussin MH, Haafiz MM, Thakur VK (2017) Recent progress in cellulose nanocrystals: sources and production. Nanoscale 9(5):1763–1786

Haafiz MM, Eichhorn S, Hassan A, Jawaid M (2013) Isolation and characterization of microcrystalline cellulose from oil palm biomass residue. Carbohydr Polym 93(2):628–634

Kalita RD, Nath Y, Ochubiojo ME, Buragohain AK (2013) Extraction and characterization of microcrystalline cellulose from fodder grass; Setaria glauca (L.) P. Beauv, and its potential as a drug delivery vehicle for isoniazid, a first line antituberculosis drug. Colloids and Surfaces B 108:85–89

Okwonna OO (2013) The effect of pulping concentration treatment on the properties of microcrystalline cellulose powder obtained from waste paper. Carbohydr Polym 98(1):721–725

Merci A, Urbano A, Grossmann MVE, Tischer CA, Mali SJ (2015) Properties of microcrystalline cellulose extracted from soybean hulls by reactive extrusion. Food Res Int 73:38–43

Trache D, Donnot A, Khimeche K, Benelmir R, Brosse N (2014) Physico-chemical properties and thermal stability of microcrystalline cellulose isolated from Alfa fibres. Carbohydr Polym 104:223–230

García-Fayos P, Gasque MJ (2006) Seed vs. microsite limitation for seedling emergence in the perennial grass Stipa tenacissima L. (Poaceae). Food Res Int 30(2):276–82

Cerdà AJJoAE (1997) The effect of patchy distribution of Stipa tenacissima L.on runoff erosion. J Arid Environ 36(1):37–51

El-Abbassi FE, Assarar M, Ayad R, Bourmaud A, Baley C, Manufacturing (2020) A review on alfa fibre (Stipa tenacissima L.): from the plant architecture to the reinforcement of polymer composites. J Compos Part A 128:105677

Bessadok A, Marais S, Gouanvé F, Colasse L, Zimmerlin I, Roudesli S et al (2007) Effect of chemical treatments of Alfa (Stipa tenacissima) fibres on water-sorption properties. J Compos Sci Technol 67(3–4):685–697

Triki A, Dittmer J, Hassen MB, Arous M, Bulou A, Gargouri M (2016) Spectroscopy analyses of hybrid unsaturated polyester composite reinforced by Alfa, wool, and thermo-binder fibres. J Polym Sci Ser A 58(2):255–264

Bouiri B, Amrani M, Chemistry E (2010) Elemental chlorine-free bleaching halfa pulp. J Ind Eng Chem 16(4):587–592

Trache D, Tarchoun AF, Derradji M, Hamidon TS, Masruchin N, Brosse N et al (2020) Nanocellulose: from fundamentals to advanced applications. Front Chem 8:192

Kargarzadeh H, Ahmad I, Thomas S, Dufresne A (2017) Handbook of nanocellulose and cellulose nanocomposites. Wiley, New York

Phanthong P, Reubroycharoen P, Hao X, Xu G, Abudula A, Guan G (2018) Nanocellulose: extraction and application. Carbon Resour Convers 1(1):32–43

Trache D, Hussin MH, Chuin CTH, Sabar S, Fazita MN, Taiwo OF et al (2016) Microcrystalline cellulose: Isolation, characterization and bio-composites application—a review. Int J Biol Macromol 93:789–804

Ilyas R, Sapuan S, Ishak M (2018) Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr Polym 181:1038–1051

Jiang F, Hsieh Y-L (2015) Cellulose nanocrystal isolation from tomato peels and assembled nanofibers. Carbohydrate Polym 122:60–8

Liao JJ, Abd Latif NH, Trache D, Brosse N, Hussin MH (2020) Current advancement on the isolation, characterization and application of lignin. Int J Biol Macromol 162:285–1024

Robles E, Fernandez-Rodriguez J, Barbosa AM, Gordobil O, Carreno NL, Labidi J (2018) Production of cellulose nanoparticles from blue agave waste treated with environmentally friendly processes. Carbohydr Polym 183:294–302

Cheng F, Zhao X, Hu Y (2018) Lignocellulosic biomass delignification using aqueous alcohol solutions with the catalysis of acidic ionic liquids: a comparison study of solvents. Bioresour Technol 249:969–975

Ren H, Shen J, Pei J, Wang Z, Peng Z, Fu S et al (2019) Characteristic microcrystalline cellulose extracted by combined acid and enzyme hydrolysis of sweet sorghum. Cellulose 26(15):8367–8381

Yiin CL, Ho S, Yusup S, Quitain AT, Chan YH, Loy ACM et al (2019) Recovery of cellulose fibers from oil palm empty fruit bunch for pulp and paper using green delignification approach. Bioresour Technol 290:121797

Garba ZN, Lawan I, Zhou W, Zhang M, Wang L, Yuan Z (2020) Microcrystalline cellulose (MCC) based materials as emerging adsorbents for the removal of dyes and heavy metals–a review. Sci Total Environ 717:135070

Kian LK, Saba N, Jawaid M, Fouad H (2020) Characterization of microcrystalline cellulose extracted from olive fiber. Int J Biol Macromol

Wardhono EY, Kanani N, Alfirano A (2020) A simple process of isolation microcrystalline cellulose using ultrasonic irradiation. J Dispersion Sci Technol 41(8):1217–1226

Standard T (1997) Solvent extractives of wood and pulp. TAPPI T.204

Kilic A, Niemz P (2012) Extractives in some tropical woods. Eur J Wood Wood Product 70(1–3):79–83

Kuznetsov B, Sudakova I, Garyntseva N, Djakovitch L, Pinel C (2017) Kinetic studies and optimization of abies wood fractionation by hydrogen peroxide under mild conditions with TiO2 catalyst. Reac Kinet Mech Catal 120(1):81–94

Rosa SM, Rehman N, de Miranda MIG, Nachtigall SM, Bica CI (2012) Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohyd Polym 87(2):1131–1138

Sun J, Sun X, Zhao H, Sun R (2004) Isolation and characterization of cellulose from sugarcane bagasse. Polym Degrad Stab 84(2):331–339

Khandanlou R, Ngoh GC, Chong WT (2016) Feasibility study and structural analysis of cellulose isolated from rice husk: Microwave irradiation, optimization, and treatment process scheme. BioResources. 11(3):5751–66

Reddy KO, Uma Maheswari C, Muzenda E, Shukla M, Rajulu AV (2016) Extraction and characterization of cellulose from pretreated ficus (peepal tree) leaf fibers. J Nat Fibers 13(1):54–64

Hu Y, Tang L, Lu Q, Wang S, Chen X, Huang B (2014) Preparation of cellulose nanocrystals and carboxylated cellulose nanocrystals from borer powder of bamboo. Cellulose 21(3):1611–8

Wise LE (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Paper Trade 122:35–43

Brahim SB, Cheikh RB, Technology (2007) Influence of fibre orientation and volume fraction on the tensile properties of unidirectional Alfa-polyester composite. Compos Sci Technol 67(1):140–147

Hattalli S, Benaboura A, Ham-Pichavant F, Nourmamode A, Castellan A, Stability (2002) Adding value to Alfa grass (Stipa tenacissima L.) soda lignin as phenolic resins 1. Lignin characterization. Polym Degrad Stab 76(2):259–264

Zaafouri K, Ziadi M, Farah RB, Farid M, Hamdi M, Regaya I (2016) Potential of Tunisian Alfa (Stipa tenassicima) fibers for energy recovery to 2G bioethanol: Study of pretreatment, enzymatic saccharification and fermentation. Biomass Bioenergy 94:66–77

Paiva M, Ammar I, Campos A, Cheikh RB, Cunha A (2007) Alfa fibres: mechanical, morphological and interfacial characterization. Compos Sci Technol 67(6):1132–1138

Hussin MH, Husin NA, Bello I, Othman N, Bakar MA, Haafiz MM (2018) Isolation of microcrystalline cellulose (MCC) from oil palm frond as potential natural filler for PVA-LiClO4 polymer electrolyte. Int J Electrochem Sci 13:3356–3371

Zhao T, Chen Z, Lin X, Ren Z, Li B, Zhang Y (2018) Preparation and characterization of microcrystalline cellulose (MCC) from tea waste. Carbohydr Polym 184:164–170

Hermawan D, Lai TK, Jafarzadeh S, Gopakumar DA, Hasan M, Owolabi FT et al (2019) Development of seaweed-based bamboo microcrystalline cellulose films intended for sustainable food packaging applications. BioResources 14(2):3389–3410

Liu Y, Nie Y, Lu X, Zhang X, He H, Pan F et al (2019) Cascade utilization of lignocellulosic biomass to high-value products. Green Chem 21(13):3499–3535

Reddy KO, Maheswari CU, Dhlamini M, Mothudi B, Kommula V, Zhang J et al (2018) Extraction and characterization of cellulose single fibers from native african napier grass. Carbohydr Polym 188:85–91

Ditzel FI, Prestes E, Carvalho BM, Demiate IM, Pinheiro LA (2017) Nanocrystalline cellulose extracted from pine wood and corncob. Carbohydr Polym 157:1577–1585

Bian J, Peng F, Peng X-P, Peng P, Xu F, Sun R-C (2012) Acetic acid enhanced purification of crude cellulose from sugarcane bagasse: structural and morphological characterization. BioResources 7(4):4626–4639

Bian J, Peng F, Peng X-P, Peng P, Xu F, Sun R-C (2012) Acetic acid enhanced purification of crude cellulose from sugarcane bagasse: structural and morphological characterization. BioResources 7(4):4626–4639

Trache D, Khimeche K, Donnot A, Benelmir R, editors. FTIR spectroscopy and X-ray powder diffraction characterization of microcrystalline cellulose obtained from alfa fibers. 39th Edition of the Joint European Days on Equilibrium between Phases; 2013

-Das K, Ray D, Bandyopadhyay N, Sengupta S (2010) Study of the properties of microcrystalline cellulose particles from different renewable resources by XRD, FTIR, nanoindentation, TGA and SEM. J Polym Environ 18(3):355–363

Kumar R, Hu F, Hubbell CA, Ragauskas AJ, Wyman CE (2013) Comparison of laboratory delignification methods, their selectivity, and impacts on physiochemical characteristics of cellulosic biomass. Bioresour Technol 130:372–381

Ramli R, Junadi N, Beg MD, Yunus RM (2015) Microcrystalline cellulose (MCC) from oil palm empty fruit bunch (EFB) fiber via simultaneous ultrasonic and alkali treatment. Chem Mol Nucl Mater Metall Eng 9(1):8–11

Wyman CE, Decker SR, Himmel ME, Brady JW, Skopec CE, Viikari L (2004) Hydrolysis of cellulose and hemicellulose. In: Dumitriu S (ed) Polysaccharides: Structural diversity and functional versatility. Boca Raton, CRC Press, pp 1023–62

Kishani S, Vilaplana F, Xu W, Xu C, Wågberg L (2018) Solubility of softwood hemicelluloses. Biomacromol 19(4):1245–1255

Abu-Thabit NY, Judeh AA, Hakeem AS, Ul-Hamid A, Umar Y, Ahmad A (2020) Isolation and characterization of microcrystalline cellulose from date seeds (Phoenix dactylifera L.). Int J Biol Macromol 155:730–739

Xiang LY, Mohammed MAP, Baharuddin AS (2016) Characterisation of microcrystalline cellulose from oil palm fibres for food applications. Carbohydr Polym 148:11–20

Francis R, Rodriguez S, Bose S, Granzow S, Evans T, editors. The critical role of transition metals in high-temperature peroxide (PO) bleaching. Annual Meeting-Technical Sction Canadian Pulp and Paper Association; 1998: Canadian Pulp & Paper ASSN-Technical Section

Ramos E, Calatrava S, Jiménez LJA (2008) Bleaching with hydrogen peroxide. A review. Afinidad 65(537)

Tarchoun AF, Trache D, Klapötke TM, Derradji M, Bessa W (2019) Ecofriendly isolation and characterization of microcrystalline cellulose from giant reed using various acidic media. Cellulose 26(13–14):7635–7651

Azubuike CP, Okhamafe AO (2012) Physicochemical, spectroscopic and thermal properties of microcrystalline cellulose derived from corn cobs. Int J Recycling Org Waste Agric 1(1):9

Bessa W, Trache D, Derradji M, Tarchoun AF (2020) Non-isothermal curing kinetics of alkali-treated alfa fibers/polybenzoxazine composites using differential scanning calorimetry. Chem Sel 5(18):5374–5386

Acknowledgements

The authors gratefully acknowledge the Ecole Militaire polytechnique for the financial support and the necessary facilities for the accomplishment of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beroual, M., Boumaza, L., Mehelli, O. et al. Physicochemical Properties and Thermal Stability of Microcrystalline Cellulose Isolated from Esparto Grass Using Different Delignification Approaches. J Polym Environ 29, 130–142 (2021). https://doi.org/10.1007/s10924-020-01858-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01858-w