Abstract

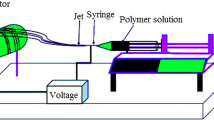

The high surface area of porous nanofibers enhances their performance for many applications. The present study investigated electrospinning and dye adsorption properties of polymeric nanofibers which were porous by various types of salts. The salt/polyacrylonitrile/polyvinylidene fluoride composite nanofibers were electrospun, and the inexpensive salts such as sodium chloride (NaCl), sodium bicarbonate (NaHCO3), or calcium chloride (CaCl2) was used to manufacture the porous fibers. Subsequently, the salt was removed by a selective dissolution, and salt extraction of nanofibers was performed with the solution of hydrochloric acid (10 wt%). Salt/PVDF/PAN and porous PVDF/PAN composite nanofibers have been applied to dye adsorption of solution. The characteristics of nanofibers were studied by Fourier transform infrared microscopy (FTIR) and scanning electron microscopy (SEM) analysis. FTIR showed that the salt was extracted from PVDF/PAN nanofibers successfully, and SEM indicated that many pores were aligned with the nanofibers. The adsorption capacity of salt nanofibers webs and porous nanofibers webs for Basic Blue 41 were compared with each other, and porous fibers were obtained from NaHCO3 having the highest dye adsorption value. Adsorption of dyes follows the Langmuir isotherm and pseudo-second order kinetics.

Similar content being viewed by others

References

Li WJ et al (2002) Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J Biomed Mater Res A 60(4):613–621

Formhals A (1934) Process and apparatus for preparing artificial threads. US Patent 1975504

Zhao S et al (2004) Electrospinning of ethyl–cyanoethyl cellulose/tetrahydrofuran solutions. J Appl Polym Sci 91(1):242–246

Qin XH et al (2007) Effect of different salts on electrospinning of polyacrylonitrile (PAN) polymer solution. J Appl Polym Sci 103(6):3865–3870

Neghlani PK, Rafizadeh M, Taromi FA (2011) Preparation of aminated-polyacrylonitrile nanofiber membranes for the adsorption of metal ions: comparison with microfibers. J Hazard Mater 186(1):182–189

Birajdar MS, Wanjale SD, Lonkar SP (2013) Morphology, polymorphism, and metal ion adsorption studies of electrospun nanofibers based on PVDF and organically modified layered double hydroxide. J Appl Polym Sci 130(6):4508–4515

Kampalanonwat P, Supaphol P (2011) Preparation of hydrolyzed electrospun polyacrylonitrile fiber mats as chelating substrates: a case study on copper (II) ions. Ind Eng Chem Res 50(21):11912–11921

Xiuli Y et al (1998) Morphology and properties of hollow-fiber membrane made by PAN mixing with small amount of PVDF. J Membr Sci 146(2):179–184

Bouaziz A, Richert A, Caprani A (1997) Vascular endothelial cell responses to different electrically charged poly(vinylidene fluoride) supports under static and oscillating flow conditions. Biomaterials 18(2):107–112

Liu T-Y et al (2005) Surface characteristics and hemocompatibility of PAN/PVDF blend membranes. Polym Adv Technol 16(5):413–419

Mehraban M et al (2013) Preparation of porous nanofibers from electrospun polyacrylonitrile/calcium carbonate composite nanofibers using porogen leaching technique. J Appl Polym Sci 128(2):926–933

Ma G, Yang D, Nie J (2009) Preparation of porous ultrafine polyacrylonitrile (PAN) fibers by electrospinning. Polym Adv Technol 20(2):147–150

Li X, Nie G (2004) Nano-porous ultra-high specific surface ultrafine fibers. Chin Sci Bull 49(22):2368–2371

Mahmoodi NM, Mokhtari-Shourijeh Z (2015) Preparation of PVA-chitosan blend nanofiber and its dye removal ability from colored wastewater. Fibers Polym 16(9):1861–1869

Mahmoodi NM, Mokhtari-Shourijeh Z, Ghane-Karade A (2017) Synthesis of the modified nanofiber as a nanoadsorbent and its dye removal ability from water: isotherm, kinetic and thermodynamic. Water Sci Technol 75(10):2475–2487

Mahmoodi NM, Mokhtari-Shourijeh Z (2016) Preparation of aminated nanoporous nanofiber by solvent casting/porogen leaching technique and dye adsorption modeling. J Taiwan Inst Chem Eng 65:378–389

Zong X et al (2002) Structure and process relationship of electrospun bioabsorbable nanofiber membranes. Polymer 43(16):4403–4412

Anvari A et al (2017) PVDF/PAN blend membrane: preparation, characterization and fouling analysis. J Polym Environ 25(4):1348–1358

Homaeigohar SS, Elbahri M (2012) Novel compaction resistant and ductile nanocomposite nanofibrous microfiltration membranes. J Colloid Interface Sci 372(1):6–15

Kim Y-J et al (2011) Characteristics of electrospun PVDF/SiO 2 composite nanofiber membranes as polymer electrolyte. Mater Chem Phys 127(1):137–142

Kampalanonwat P, Supaphol P (2010) Preparation and adsorption behavior of aminated electrospun polyacrylonitrile nanofiber mats for heavy metal ion removal. ACS Appl Mater Interfaces 2(12):3619–3627

Nirmala R et al (2011) Hydroxyapatite mineralization on the calcium chloride blended polyurethane nanofiber via biomimetic method. Nanoscale Res Lett 6(1):2

Ding W et al (2010) Manipulated electrospun PVA nanofibers with inexpensive salts. Macromol Mater Eng 295(10):958–965

Akhtar MN et al (2015) Evaluation of thermal, morphological and mechanical properties of PMMA/NaCl/DMF electrospun nanofibers: an investigation through surface methodology approach. Iran Polym J 24(12):1025–1038

Mahmoodi NM, Mokhtari-Shourijeh Z (2016) Modified poly (vinyl alcohol)-triethylenetetramine nanofiber by glutaraldehyde: preparation and dye removal ability from wastewater. Desalination Water Treat 57(42):20076–20083

Pirkarami A, Olya ME, Limaee NY (2013) Decolorization of azo dyes by photo electro adsorption process using polyaniline coated electrode. Prog Org Coat 76(4):682–688

Arafat HA, Franz M, Pinto NG (1999) Effect of salt on the mechanism of adsorption of aromatics on activated carbon. Langmuir 15(18):5997–6003

Hameed B, Ahmad A, Aziz N (2007) Isotherms, kinetics and thermodynamics of acid dye adsorption on activated palm ash. Chem Eng J 133(1):195–203

Dada A et al (2012) Langmuir, Freundlich, Temkin and Dubinin–Radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. IOSR J Appl Chem 3(1):38–45

Saeed K et al (2008) Preparation of amidoxime-modified polyacrylonitrile (PAN-oxime) nanofibers and their applications to metal ions adsorption. J Membr Sci 322(2):400–405

Limousin G et al (2007) Sorption isotherms: a review on physical bases, modeling and measurement. Appl Geochem 22(2):249–275

Lee C-R et al (2011) Pseudo first-order adsorption kinetics of N719 dye on TiO2 surface. ACS Appl Mater Interfaces 3(6):1953–1957

Lagergren S (1898) About the theory of so-called adsorption of soluble substances. Kungl Sv Vet-akademiens Handlingar 24(4):1–39

Qiu H et al (2009) Critical review in adsorption kinetic models. J Zhejiang Univ Sci A 10(5):716–724

Ho YS, McKay G (1998) A comparison of chemisorption kinetic models applied to pollutant removal on various sorbents. Process Saf Environ Prot 76(4):332–340

Cheung W, Szeto Y, McKay G (2007) Intraparticle diffusion processes during acid dye adsorption onto chitosan. Bioresour Technol 98(15):2897–2904

Al-Degs YS et al (2006) Sorption of Zn(II), Pb(II), and Co(II) using natural sorbents: equilibrium and kinetic studies. Water Res 40(14):2645–2658

Yazdani MR et al (2016) Adsorptive removal of arsenic(V) from aqueous phase by feldspars: kinetics, mechanism, and thermodynamic aspects of adsorption. J Mol Liq 214:149–156

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mokhtari-Shourijeh, Z., Montazerghaem, L. & Olya, M.E. Preparation of Porous Nanofibers from Electrospun Polyacrylonitrile/Polyvinylidene Fluoride Composite Nanofibers by Inexpensive Salt Using for Dye Adsorption. J Polym Environ 26, 3550–3563 (2018). https://doi.org/10.1007/s10924-018-1238-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1238-z