Abstract

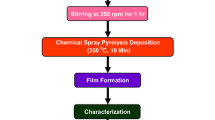

Copper sulfide (CuS) rod shaped nanostructures with an average length 8 to 10 nm are synthesized through green chemical route using biodegradable starch as a capping agent under a nitrogen environment. Owing to the presence of a large number of glucose units linked by glycosidic bonds, starch can cap copper sulfide (CuS) nanoparticles. The preparation of CuS under nitrogen atmosphere produces fine quality CuS nanostructures by minimizing oxidation. XRD pattern reveals pure hexagonal covellite type CuS nanostructure with prime diffraction planes along (101), (102), (103), (006), (008), and (110) directions. The lattice parameters estimated as a = 3.790 Å and c = 16.51 Å. HRTEM studies show a well distribution of CuS nanorods. It shows prominent d-value of 0.28 nm corresponding to (103) hexagonal plane of CuS. The optical absorption extended up to 364 nm which is fairly blue shifted over bulk owing to the quantum confinement brought by starch. The photoluminescence emission is observed at 525 nm. The I–V measurements in planar geometry exhibit the linearity that reveals the ohmic behavior of carrier transport in CuS nanostructures. CuS nanostructures have been successfully used as effective p-type layer to fabricate sandwiched heterojunction devices with zinc chalcogenides (ZnO/ZnS and ZnS/ZnO) core/shell nanocomposites. The p-CuS/n-(zinc chalcogenides) heterojunction devices show good diode characteristics with an increase of ideality factor that may be attributed to surface defects and inhomogeneity in the barrier height. The photodetector also exhibits promising characteristics in terms of responsivity and quantum efficiency which are significant corresponding to material properties.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

L.Z. Pei, J.F. Wang, X.X. Tao, S.B. Wang, Y.P. Dong, C.G. Fan, Q.F. Zhang, Mater. Charact. 62, 354 (2011). https://doi.org/10.1016/j.matchar.2011.01.001

R. Khunphonoi, K. Wantala, N. Grisdanurak, Environ. Eng. Res. 26, 190484 (2021). https://doi.org/10.4491/eer.2019.484

Adel H. Omran Al-khayatt, Mustafa D. Jaafer, J. Kufa Phys. 5, 79–90 (2013)

L.A. Isac, A. Duta, A. Kriza, I.A. Enesca, M. Nanu, J. Phys. Conf. Ser. 61, 477–481 (2007)

J. Kundu, D. Pradhan, New J. Chem. 37, 1470 (2013). https://doi.org/10.1039/c3nj41142g

A.U. Ubale, D.M. Choudhari, J.S. Kantale, V.N. Mitkari, M.S. Nikam, W.J. Gawande, P.P. Patil, J. Alloys Compd. 509, 9249 (2011). https://doi.org/10.1016/j.jallcom.2011.07.009

X.H. Liao, N.Y. Chen, S. Xu, S. Bin Yang, J.J. Zhu, J. Cryst. Growth 252, 593 (2003). https://doi.org/10.1016/S0022-0248(03)01030-3

R.S. Christy, J. Thampi, T. Kumaran, J. Non-Oxide Glas. 6, 13 (2014)

M. Saranya, C. Santhosh, R. Ramachandran, P. Kollu, P. Saravanan, M. Vinoba, S.K. Jeong, A.N. Grace, Powder Technol. 252, 25 (2014)

I.Puspitasari, T.P.Gujar, K.D.Jung, Mat.Sci.Eng.140, 199 (2007)

M.T.S. Nair, L. Guerrero, P.K. Nair, Semicond. Sci. Technol. 13, 1164 (1998)

J.S. Cruz, S.A.M. Hernandez, F.P. Delgado, O.Z. Angel, R.C. Perez, G.T. Delgado, Int. J. Photoenergy 2013, 178017 (2013). https://doi.org/10.1155/2013/178017

X. Qian, J. Fang, Y. Song, Proc. of SPIE 7381, 26 (2013)

J.-H. Lim, C.-K. Kang, K.-K. Kim, I.-K. Park, D.-K. Hwang, S.-J. Park, Adv. Mater. 18, 2720 (2006)

S.M. Hatch, J. Briscoe, S. Dunn, Adv. Mater. 25, 867 (2013)

L. Zheng, F. Teng, Z. Zhang, B. Zhao, X. Fang, J. Mater. Chem. C 4, 10032 (2016)

L.Q. Qin, C. Shing, S. Sawyer, P.S. Dutta, Opt. Mater. 33, 359 (2011)

H. Lin, L. Wei, C. Wu, Y. Chen, S. Yan, L.Mei and J. Jiao, Nanoscale Res. Lett. 11, 420 (2016)

X. Huang, M. Wang, M.G. Willinger, L.D. Shao, D.S. Su, X.M. Meng, ACS Nano. 6, 7333 (2012). https://doi.org/10.1021/nn3024514

L.F. Hu, J. Yan, M.Y. Liao, H.J. Xiang, X.G. Gong, L.D. Zhang, X.S. Fang, Adv Mater 24, 2305 (2012)

M. Sookhakian, Y.M. Amin, W.J. Basirun, M.T. .Tajabadi, N.Kamarulzaman, J. Lumin. 145, 244 (2014)

J. Li, D. Zhao, X. Meng, Z. Zhang, J. Zhang, D. Shen, Y. Lu, X. Fan, J. Phys. Chem. B 110, 14685 (2006)

R. Xie, X. Zhong and T. Basche, Adv. Mater. 17, 2741 (2005)

L. Hu, J.Yan, M.Liao, H.Xiang, X.Gong, L.Zhang, X. Fang, Adv. Mater. 24, 2305 (2012). https://doi.org/10.1002/adma.201200512

A. Sadollahkhani, I. Kazeminezhad, J. Lu, O.Nur, L. Hultman and M. Willander, RSC Adv. 4, 36940 (2014). https://doi.org/10.1039/C4RA05247A

S.Thakur, N.Sharma, A.Varkia and J. Kumar, Pelagia Res. Libr. 5, 18 (2014)

M.Babikier, D.Wang, J.Wang,Q. Li, J. Sun, Y. Yan, Q. Yu and S. Jiao, Nanoscale Res. Lett. 9, 199 (2014)

S. Yadav, P.K. Bajpai, Nano-Struct. Nano-Objects 10, 151 (2017). https://doi.org/10.1016/j.nanoso.2017.03.009

J. Podder, R. Kobayashi, M. Ichimura, Thin Solid Films 472, 71 (2005). https://doi.org/10.1016/j.tsf.2004.06.137

N. Mukherjee, A. Sinha, G.G. Khan, D. Chandra, A. Bhaumik, A. Mondal, Mater. Res. Bull. 46, 6 (2011). https://doi.org/10.1016/j.materresbull.2010.10.004

S. Deb, P.K. Kalita, P. Datta, Int. J. Nanosci. 16, 1760032 (2017). https://doi.org/10.1142/S0219581X17600328

K. Vishwakarma, Ph.D. Thesis, National Institute of Technology, 2013

S. Deb, Ph.D. Thesis, Gauhati University, 2017

P. Raveendran, J. Fu, S.L. Wallen, J. Am. Chem. Soc. 125, 13940 (2003)

S.I. Raj, A. Jaiswal, I. Uddinb, RSC Adv. 10, 14050 (2020)

C.M. Simonescu, L. Patron, V.S. Teodorescu, M. Brezeanu, C. Capatina, J. Optoelectron. Adv. Mater. 8, 597 (2006)

M.M. Kamazani, Z. Zarghami, M.S. Niasari, J. Phys. Chem. C 120, 2096 (2016). https://doi.org/10.1021/acs.jpcc.5b11566

S. Deb, P.K. Kalita, P. Datta, Phys. Scr. 95, 095810 (2020). https://doi.org/10.1088/1402-4896/abac75

Y. Huang, H. Xiao, S. Chen, C. Wang, Ceram. Int. 35, 905 (2009). https://doi.org/10.1016/j.ceramint.2008.02.003

E. Godocíkova, P. Balaz, J.M. Criado, C. Real, E. Gock, Thermochim. Acta 440, 19 (2006). https://doi.org/10.1016/j.tca.2005.09.015

B.D. Cullity, Elements of X-Ray Diffraction (Addison Wesley, New York, 1978)

X. Xu, J. Bullock, L.T. Schelhas, E.Z. Stutz, J.J. Fonseca, M. Hettick, V.L. Pool, K.F. Tai, M.F. Toney, X. Fang, A. Javey, L.H. Wong, J.W. Ager, Nano Lett. 16, 1925 (2016). https://doi.org/10.1021/acs.nanolett.5b05124

P.A. Ajibade, N.L. Botha, Synthesis, Nanomaterials 7, 32 (2017). https://doi.org/10.3390/nano7020032

A.D. Dhondge, S.R. Gosavi, N.M. Gosavi, C.P. Sawant, A.M. Patil, A.R. Shelke, N.G. Deshpande, World J. Condens. Matter Phys. 5, 1 (2015)

M. Sze, M.K. Lee, Physics of Semiconductor Devices, 3rd edn. (Wiley, New York, 2006)

M.J. Jing, J.K. Xin, L.B. Cheng, F. Fei, X. Hui, Z.C. Chao, C.C. Le, Chin. Phys. Lett. 27, 107304 (2010). https://doi.org/10.1088/0256-307X/27/10/107304

A. N. Corpus-Mendoza, M. M. De Souza and F. Hamelmann J. Appl. Phys. 114, 184505 (2013). https://doi.org/10.1063/1.4831661

S.M. Faraz, W. Shah, N.U.H. Alvi, O. Nur, Q.U. Wahab, Adv. Condens. Matter Phys. 2020, 6410573 (2020). https://doi.org/10.1155/2020/6410573

N.N. Jandow, F.K. Yam, S.M. Thahab, H.A. Hassan and K. Ibrahim, Curr. Appl. Phys. 10, 1452 (2010)

Acknowledgements

The authors gratefully acknowledge the technical support of the Department of Physics, IIT-Guwahati for XRD analysis and I–V characteristics, Sophisticated Analytic Instrument Facility (NEHU) Shillong for HRTEM analysis and Department of Chemistry, Gauhati University for optical analysis.

Funding

No funding was received for this work.

Author information

Authors and Affiliations

Contributions

We confirm that all authors contributed significantly to the creation of this manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deb, S., Kalita, P.K. Green synthesis of copper sulfide (CuS) nanostructures for heterojunction diode applications. J Mater Sci: Mater Electron 32, 24125–24137 (2021). https://doi.org/10.1007/s10854-021-06879-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06879-2