Abstract

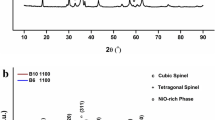

The effect of B2O3 addition on the electrical and microstructural properties of Ni0.5Co0.5ZnxMn2 − xO4 (where x = 0.15 and 0.3) negative temperature coefficient (NTC) thermistors was investigated. Ni0.5Co0.5Zn0.15Mn1.85O4 and Ni0.5Co0.5Zn0.3Mn1.7O4 samples were calcined at 900 °C and then sintered at 1100, 1200 and 1300 °C. Ni0.5Co0.5Zn0.15Mn1.85O4 + 0.1 mol B2O3 and Ni0.5Co0.5Zn0.3Mn1.7O4 + 0.1 mol B2O3 added samples were sintered at 900, 1000 and 1100 °C without applying calcination. The B2O3-doped samples sintered at 1100 °C without calcination gave rise to very similar crystal structure with un-doped sample. All samples sintered at 1100 °C consisted of a major cubic spinel phase, a minor tetragonal spinel and a minor NiO-rich phase. In addition, no peaks related to B2O3 or ZnO additions were observed. This result demonstrated that the B ions and Zn ions dissolved into the lattice. The bulk density and grain size of B2O3-doped samples without applying calcination were similar to calcined un-doped samples when all the samples were sintered at 1100 °C. It was also observed that the increase in Zn content had minimal effect on the bulk density and grain size of samples. The electrical resistivity and material constant for Ni0.5Co0.5Zn0.3Mn1.7O4 sample were 2475 Ω cm and 3660 K and for Ni0.5Co0.5Zn0.3Mn1.7O4 + 0.1 mol B2O3 sample were 1570 Ω cm and 3725 K when the samples were sintered at 1100 °C. NTC thermistor having lower electrical resistivity and higher material constant can be achieved with the addition of B2O3 without applying calcination.

Similar content being viewed by others

References

A. Feteira, J. Am. Ceram. Soc. 92, 967–983 (2009)

C. Zhao, Y. Zhao, J. Mater. Sci. 23, 1788–1792 (2012)

J. Kulawik, D. Szwagierczak, B. Gröger, A. Skwarek, Micro. Int. 24(2), 14–18 (2007)

P. Regtien, Sensors for mechatronics (Elsevier, Netherlands, 2012)

C.C. Wang, S.A. Akbar, M.J. Madou, J. Electroceram. 2(4), 273–282 (1998)

Q. Wang, W. Kong, J.C. Yao, A. Chang, Ceram. Int. 45, 378–383 (2019)

C. Ma, Y. Liu, Y. Lu, J. Mater. Sci. 26, 7238–7243 (2015)

W. Kong, B. Gao, C. Jiang, A. Chang, J. Alloys Compd. 650, 305–310 (2015)

K. Park, I.H. Han, J. Electroceram. 17, 1069–1073 (2006)

K. Park, J.K. Lee, Scripta Mater. 57, 329–332 (2007)

H. Han, K.R. Park, Y.R. Hong, K. Shim, S. Mhin, J. Alloys Compd. 732, 486–490 (2018)

C. Peng, H. Zhang, A. Chang, F. Guan, B. Zhang, P. Zhao, J. Mater. Sci. 23, 851–857 (2012)

B. Yüksel Price, G. Hardal, J. Mater. Sci 27, 9226–9232 (2016)

R. Schmidt, A. Basu, A.W. Brinkman, Phys. Rev. B 72, 115101 (2005)

Z. Yang, H. Zhang, Z. He, B. Li, Z. Li, J. Mater. Sci. 30, 3088–3097 (2019)

E.G. Larson, R.J. Arnott, D.G. Wickham, J. Phys. Chem. Solids 23, 1771–1781 (1962)

R.N. Jadhav, V. Puri, J. Alloys Compd. 507, 151–156 (2010)

J.-J. Qu, X.-Q. Li, F. Liu, C.-L. Yuan, X. Liu, H.-W. Ning, H.-L. Li, Mater. Sci 30, 4688–4695 (2019)

X. Liu, J. Wang, Z. Hu, J. Yao, A. Chang, Mater. Sci 28, 7243–7247 (2017)

H. Han, H. Lee, J. Lim, K.M. Kim, Y.R. Hong, J. Lee, J. Forrester, J.H. Ryu, S. Mhin, Ceram. Int. 43, 16070–16075 (2017)

K. Xiong, S. Zhao, D. Li, H. Bao, C. Nan, J. Alloys Compd. 606, 273–277 (2014)

D. Li, S. Zhao, K. Xiong, H. Bao, C. Nan, J. Alloys Compd. 582, 283–288 (2014)

Q. Shi, W. Ren, W. Kong, B. Gao, L. Wang, C. Ma, A. Chang, L. Bian, J. Mater. Sci. 28, 9876–9881 (2017)

H. Gao, C. Ma, B. Sun, J. Mater. Sci. 25, 3990–3995 (2014)

M.N. Muralidharan, P.R. Rohini, E.K. Sunny, K.R. Dayas, A. Seema, Ceram. Int. 38, 6481–6486 (2012)

C. Zhao, B. Wang, P. Yang, L. Winnubst, C. Chen, J. Eur. Ceram. Soc. 28, 35–40 (2008)

X. Xie, M. Chen, T. Liu, H. Jiang, H. Zhang, A. Chang, J. Mater. Sci. 28, 190–196 (2017)

Kwon OH (2001) Encyclopedia of materials: science and technology- liquid phase sintering: ceramics. Mahajan S Elsevier Science, Amsterdam, p 4597–4601

W. Kong, L. Chen, B. Gao, B. Zhang, P. Zhao, G. Ji, A. Chang, C. Jiang, Ceram. Inter. 40, 8405–8409 (2014)

H. Naceur, A. Megriche, M. El-Maaoui, J Adv. Ceram. 3, 17–30 (2014)

K. Terayama, M. Ikeda, Trans. Jpn. Inst. Met. 24, 754–758 (1983)

J. Jung, J. Töpfer, J. Mürbe, A. Feltz, J. Eur. Ceram. Soc. 6, 351–359 (1990)

F. Cheng, J. Wang, H. Zhang, A. Chang, W. Kong, B. Zhang, L. Chen, J. Mater. Sci. 26, 1374–1380 (2015)

D. Fang, C. Zheng, C. Chen, A.J.A. Winnubst, J. Electroceram. 22, 421–427 (2009)

M. Guan, J. Yao, W. Kong, J. Wang, A. Chang, J. Mater. Sci. 29, 5082–5086 (2018)

C. Ma, H. Gao, J. Alloys Compd. 749, 853–858 (2018)

C. Ma, Y. Liu, Y. Lu, H. Gao, H. Qian, J. Ding, Mater. Sci. Eng., B 188, 66–71 (2014)

M. Hosseini, B. Yasaei, Ceram. Inter. 24, 543–545 (1998)

H. Zeng, Y. Wu, J. Zhang, C. Kuang, M. Yue, S. Zhou, Prog. Nat. Sci. 23(1), 18–22 (2013)

L. Chen, W. Kong, J. Yao, B. Gao, Q. Zhang, H. Bu, A. Chang, C. Jiang, J. Mater. Sci. 27, 1713–1718 (2016)

C. Ma, Y. Liu, Y. Lu, H. Gao, H. Qian, J. Ding, J. Mater. Sci. 24, 5183–5188 (2013)

J. Töpfer, A. Feltz, P. Dordor, J.P. Doumerc, Mater. Res. Bull. 29, 225–232 (1994)

M.L.M. Sarrión, M. Morales, J. Am. Ceram. Soc. 78, 915–921 (1995)

C. Metzmacher, R. Mikkenie, W.A. Groen, J. Eur. Ceram. Soc. 20, 997–1002 (2000)

K. Park, J.K. Lee, S.-J. Kim, W.-S. Seo, W.-S. Cho, C.-W. Lee, S. Nahm, J. Alloys Compd. 467, 310–316 (2009)

H. Zhang, A. Chang, C. Peng, Microelectr. Eng. 88, 2934–2940 (2011)

Acknowledgements

This study was supported by TÜBİTAK (The Scientific and Technical Research Council of Turkey), Project Number 3001-114M860. We would like to thank TÜBİTAK for its financial support. This work was supported by Scientific Research Projects Coordination Unit of Istanbul University, Project number 52971. This publication uses data collected within the framework of the ongoing PhD study by Gokhan Hardal.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yüksel Price, B., Hardal, G. Preparation and characterization of Ni–Co–Zn–Mn–O negative temperature coefficient thermistors with B2O3 addition. J Mater Sci: Mater Electron 30, 17432–17439 (2019). https://doi.org/10.1007/s10854-019-02093-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02093-3