Abstract

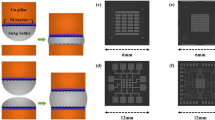

The mechanical properties of solder joints highly depend on the interfacial reaction between the solders and the metallization on substrates. In this work, we electroplated Co–P films with various compositions on the Cu pads of printed circuit boards and fabricated Sn-3.8 wt% Ag-0.7 wt% Cu/Co–P ball grid array (BGA) solder joints. The BGA solder joints were annealed at 150 °C for 100, 200, 500, and 1000 h and the shear strength of these joints was measured. When the P content of the Co–P metallization was increased from 2.3 to 18.8 at.%, the shear strength after 1000 h annealing initially rose to 107.9 MPa at a P content of 8.5 at.%, then decreased to 84.3 MPa at a P content of 12.5 at.%, and again increased to 96.0 MPa at a P content of 18.8 at.%. The enhancement of the shear strength of the joints with Co-8.5 at.% P, Co-12.5 at.% P, and Co-18.8 at.% P films was 109.5%, 63.7%, and 86.4% in comparison to the joints without Co–P metallization, respectively. The interfacial reaction between the Sn–Ag–Cu (SAC) solder and Co–P films during annealing and the fractured surfaces of the solder joints after the shear test were studied. For the joints with Co-8.5 at.% P and Co-18.8 at.% P films, a thick layer of CoSn3 was formed at the interfaces during annealing, which enhanced the shear strength. For the joints with Co-12.5 at.% P metallization, a thin layer of Co–Sn–P was formed at the interfaces and was peeled off layer by layer with prolongation of the annealing time. The spalled Co–Sn–P was mixed with the solder matrix, increasing the shear strength of the solder joints. The shear strength of the SAC/Co-12.5 at.% P joints was less than that of the joints with Co-8.5 at.% P and Co-18.8 at.% P films because no CoSn3 formed. Therefore, the composition of Co–P metallization played an important role in the interfacial reaction of the SAC/Co–P solder joints, which in turn affected the shear strength of the solder joints. Our experimental results show that the electroplated Co–P film is a promising candidate as the metallization for BGA solder joints.

Similar content being viewed by others

References

J. Wu, S.B. Xue, J.W. Wang, S. Liu, Y.L. Han, L.J. Wang, J. Mater. Sci.: Mater. Electron. 27, 12729 (2016)

D.A.A. Shnawah, S.B.M. Said, M.F.M. Sabri, I.A. Badruddin, F.X. Che, Microelectron. Reliab. 52, 2701 (2012)

K. Choi, D.Y. Yu, S. Ahn, K.H. Kim, J.H. Bang, Y.H. Ko, Microelectron. Reliab. 86, 66 (2018)

A.S.M.A. Haseeb, M.M. Arafat, S.L. Tay, Y.M. Leong, J. Electron. Mater. 46, 5503 (2017)

L. Zhang, J.G. Han, C.W. He, Y.H. Guo, J. Mater. Sci.: Mater. Electron. 24, 172 (2013)

T. Laurila, V. Vuorinen, J.K. Kivilahti, Mater. Sci. Eng. R 49, 1 (2005)

Y.H. Hsiao, K.L. Lin, J. Mater. Sci.: Mater. Electron. 27, 2201 (2016)

J.H. Seo, S.W. Yoon, K.H. Kim, H.J. Chang, K.B. Lee, T.Y. Seong, E. Fleury, J.P. Ahn, Microsc. Microanal. 19, 49 (2013)

Y. Yang, J.N. Balaraju, Y. Huang, Y.Y. Tay, Y. Shen, Z. Tsakadze, Z. Chen, J. Electron. Mater. 43, 4103 (2014)

K.J. Wang, J.G. Duh, J. Electron. Mater. 41, 757 (2012)

C.L. Liang, K.L. Lin, P.J. Cheng, J. Mater. Sci.: Mater. Electron. 29, 15233 (2018)

F.C. Tai, K.J. Wang, J.G. Duh, Scripta Mater. 61, 748 (2009)

R. Novakovic, T. Lanata, S. Delsante, G. Borzone, Mater. Chem. Phys. 137, 458 (2012)

H.C. Pan, T.E. Hsieh, Mater. Sci. Eng. B 177, 61 (2012)

J.W. Yoon, J.H. Back, S.B. Jung, J. Mater. Sci.: Mater. Electron. 29, 4724 (2018)

B.S. Lee, Y.H. Ko, J.H. Bang, C.W. Lee, S. Yoo, J.K. Kim, J.W. Yoon, Microelectron. Reliab. 71, 119 (2017)

G. Yang, D. Yang, L. Li, Microelectron. Reliab. 55, 2403 (2015)

S. Li, D. Yang, Q. Tan, L. Li, J. Electron. Mater. 44, 2007 (2015)

P. Ratchev, B. Vandevelde, I.D. Wolf, IEEE Trans. Device Mater. Reliab. 4, 5 (2004)

Y.G. Kong, Z.G. Kong, F.M. Shi, Rare Met. 36, 193 (2017)

S. Tan, J. Han, F. Guo, J. Electron. Mater. 47, 4156 (2018)

L.Y. Gao, H. Zhang, C.F. Li, J. Guo, Z.Q. Liu, J. Mater. Sci. Technol. 34, 1305 (2018)

H. Zhou, J. Guo, Q. Zhu, J. Shang, J. Mater. Sci. Technol. 29, 7 (2013)

T.J. Kim, Y.M. Kim, Y.H. Kim, J. Alloys Compd. 535, 33 (2012)

P.Y. Chia, A.S.M.A. Haseeb, J. Mater. Sci.: Mater. Electron. 24, 3423 (2013)

S.H. Wu, Y.J. Hu, C.T. Lu, T.S. Huang, Y.H. Chang, C.Y. Liu, J. Electron. Mater. 41, 3342 (2012)

C.F. Tseng, T.Y. Lee, G. Ramakrishna, K.C. Liu, J.G. Duh, Mater. Lett. 65, 3216 (2011)

C.P. Lin, C.M. Chen, Microelectron. Reliab. 52, 385 (2012)

G. Humpston, J. Mater. Sci. Mater. Electron. 21, 584 (2010)

R. Labie, P. Ratchev, E. Beyne, In: Proceeding of 55th Electronic Components and Technology Conference (ECTC 2005), p. 449 (2005)

N. Lu, D. Yang, L. Li, Acta Mater. 61, 4581 (2013)

C.H. Wang, S.E. Huang, C.W. Chiu, J. Alloys Compd. 619, 474 (2015)

C.H. Wang, C.C. Wen, C.Y. Lin, J. Alloys Compd. 662, 475 (2016)

L. Magagnin, V. Sirtori, S. Seregni, A. Origo, P.L. Cavallotti, Electrochim. Acta 50, 4621 (2005)

W.C. Wu, T.E. Hsieh, H.C. Pan, J. Electrochem. Soc. 155, D369 (2008)

H.C. Pan, T.E. Hsieh, J. Electrochem. Soc. 158, P123 (2011)

H. Chen, Y.L. Tsai, Y.T. Chang, A.T. Wu, J. Alloys Compd. 671, 100 (2016)

D. Yang, J. Cai, Q. Wang, J.W. Li, Y. Hu, L. Li, In Proceeding of 6th Electronic System-Integration Technology Conference (ESTC 2016., p. 1, (2016) https://doi.org/10.1109/ESTC.2016.7764519

D. Yang, J. Cai, Q. Wang, J. Li, Y. Hu, L. Li, J. Mater. Sci.: Mater. Electron. 26, 962 (2015)

N. Lu, J. Cai, L. Li, Surf. Coat. Technol. 206, 4822 (2012)

W.S. Rasband, ImageJ. U. S. National Institutes of Health, Bethesda, Maryland, USA. https://imagej.nih.gov/ij/. Accessed 16 Apr 2018

J.H. Hong, H.Y. Lee, A.T. Wu, J. Alloys Compd. 580, 195 (2013)

S.K. Lin, K.D. Chen, H. Chen, W.K. Liou, Y.W. Yen, J. Mater. Res. 25, 2278 (2010)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51572149), National Key Research and Development Program of China (Grant No. 2016YFA0201003), and National Basic Research Program of China (Grant No. 2013CB632504). We thank Dr. Donghua Yang at Chongqing University of Technology for his help on the preparation of SEM samples and Prof. Yunhan Ling at Tsinghua University for his help on the multi-pulse electroplating.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, S., Hu, B., Hu, Y. et al. Dependence of shear strength of Sn–3.8Ag–0.7Cu/Co–P solder joints on the P content of Co–P metallization. J Mater Sci: Mater Electron 30, 5249–5256 (2019). https://doi.org/10.1007/s10854-019-00824-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00824-0