Abstract

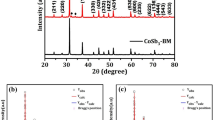

The mesostructured skutterudites Co4Sb11.5Te0.5 + nano-TiN composites are prepared through ball milling and spark plasma sintering (SPS). The influence of the various SPS temperatures within the range of 813–933 K on the microstructure and thermoelectric properties are focus in this work. The average grain sizes of the skutterudites increase from ~ 110 to ~ 500 nm with the increasing SPS temperature, while the densities of composites decrease from 7.02 to 6.26 g cm−3. Additionally, the phase of CoTe2 is detected in the samples sintered at 903–933 K. With the SPS temperature increasing from 813 to 903 K, the electrical conductivity and thermal conductivity increase simultaneously, and then decrease when SPS temperature rises to 933 K. The absolute value of Seebeck coefficient shows no clear changes when SPS temperature is not higher than 873 K but then slightly decreases with the increasing of SPS temperature. At last, the optimum SPS temperature is determined as 873 K, the ZT value of 1.07 at 800 K for the sample SPSed at 873 K is obtained, which is 11.5% higher than that of the sample SPSed at 903 K.

Similar content being viewed by others

References

L.E. Bell, Science 321, 1457–1461 (2008)

G.J. Snyder, E.S. Toberer, Nat. Mater. 7, 105–114 (2008)

M.R. Bravo, A. Moure, J.F. Fernández, M.M. González, RSC Adv. 5, 41653–41667 (2015)

H. Anno, K. Matsubara, Y. Notohara, T. Sakakibara, H. Tashiro, J. Appl. Phys. 86, 3780–3786 (1999)

E. Alleno, E. Zehani, M. Gaborit, V. Orodniichuk, B. Lenoir, M. Benyahia, J. Alloy. Compd. 692, 676–686 (2017)

T. Dahal, Q. Jie, G. Joshi, S. Chen, C.F. Guo, Y.C. Lan, Z.F. Ren, Acta. Mater. 75, 316–321 (2014)

L. Deng, H.A. Ma, T.C. Su, F.R. Yu, Y.J. Tian, Y.P. Jiang, N. Dong, S.Z. Zheng, X. Jia, Mater. Lett. 63, 2139–2141 (2009)

M.S. Toprak, C. Stiewe, D. Platzek, S. Williams, L. Bertini, E. Müller, C. Gatti, Y. Zhang, M. Rowe, M. Muhammed, Adv. Funct. Mater. 14, 1189–1196 (2004)

X.Y. Zhou, G.Y. Wang, L. Zhang, H. Chi, X.L. Su, J. Sakamoto, C. Uher, J. Mater. Chem. 22, 2958–2964 (2012)

J.L. Mi, T.J. Zhu, X.B. Zhao, J. Ma, J. Appl. Phys. 101, 054314 (2007)

H. Li, X.F. Tang, X.L. Su, Q.J. Zhang, C. Uher, J. Phys. D 42, 145409 (2009)

B. Feng, J. Xie, G.S. Cao, T.J. Zhu, X.B. Zhao, J. Mater. Chem. A 1, 13111 (2013)

P.F. Wen, H.J. Yang, X.L. Zhou, B. Duan, P.C. Zhai, Mater. Lett. 223, 190–193 (2018)

S. Bathula, M. Jayasimhadri, B. Gahtori, N.K. Singh, K. Tyagi, A.K. Srivastava, A. Dhar, Nanoscale 7, 12474–12483 (2015)

A. Khan, M. Saleemi, M. Johnsson, L. Han, N.V. Nong, M. Muhammed, M.S. Toprak, J. Alloy. Compd. 612, 293–300 (2014)

W.S. Liu, B.P. Zhang, J.F. Li, L.D. Zhao, J. Phys. D 40, 566–572 (2007)

P.F. Wen, B. Duan, P.C. Zhai, P. Li, Q.J. Zhang, J. Mater. Sci-Mater. El. 24, 5155–5161 (2013)

D.S. Stone, K.B. Yoder, W.D. Sproul, J. Vac. Sci. Technol. A 9, 2543–2547 (1991)

G. Rogl, P. Rogl, Sci. Adv. Mater. 3, 517–538 (2011)

A. Usenko, D. Moskovskikh, A. Korotitskiy, M. Gorshenkov, E. Zakharova, A. Fedorov, Y. Parkhomenko, V. Khovaylo, Scripta Mater. 146, 295–299 (2018)

P. Scherrer, Math. Phys. Klasse. 2, 98–100 (1918)

Z. Qin, K.F. Cai, S. Chen, Y. Du, J. Mater. Sci-Mater. El. 24, 4142–4147 (2013)

J. Pei, B.P. Zhang, J.F. Li, D.D. Liang, J. Alloy. Compd. 728, 694–700 (2017)

S.S. Lim, J.H. Kim, B. Kwon, S.K. Kim, H.H. Park, K.S. Lee, J.M. Baik, W.J. Choi, D.I. Kim, D.B. Hyun, J.S. Kim, S.H. Baek, J. Alloy. Compd. 678, 396–402 (2016)

C.C. Zhang, X.A. Fan, J. Hu, C.P. Jiang, B. Feng, Q.S. Xiang, G.Q. Li, Y.W. Li, Adv. Eng. Mater. 18, 1777–1784 (2016)

R. Landauer, J. Appl. Phys. 23, 779–784 (1952)

A.U. Khan, K. Kobayashi, D.M. Tang, Y. Yamauchi, K. Hasegawa, M. Mitome, Y.M. Xue, B.Z. Jiang, K. Tsuchiya, D. Golberg, Y. Bando, T. Mori, Nano Energy 31, 152–159 (2017)

W.Y. Zhao, P. Wei, Q.J. Zhang, W.T. Zhu, X.L. Su, X.F. Tang, J.H. Yang, Y. Liu, J. Shi, Y.M. Chao, S.Q. Lin, Y.Z. Pei, Nat. Nanotechnol. 12, 55–60 (2017)

B.C. Sales, B.C. Chakoumakos, V. Keppens, J.R. Thompson, Phys. Rev. B 56, 15081–15089 (1997)

C.W. Nan, R. Birringer, Phys. Rev. B 57, 8264–8268 (1998)

M. Takashiri, S. Tanaka, H. Hagino, K. Miyazaki, J. Appl. Phys. 112, 084315 (2012)

P.F. Wen, P. Li, Q.J. Zhang, F.J. Yi, L.S. Liu, P.C. Zhai, J. Electron. Mater. 38, 1200–1205 (2009)

Acknowledgements

This study is supported by the National Natural Science Foundation of China (11402182, 11502182), the Fundamental Research Funds for the Central Universities (WUT: 2017IA003. 2018IB002), and the open foundation of Hubei Key Laboratory of Theory and Application of Advanced Materials Mechanics (WUT: TAM201802).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, H., Wen, P., Zhu, Y. et al. Effects of sintering temperature on the microstructure and thermoelectric properties of mesostructured Co4Sb11.5Te0.5 skutterudites dispersed nano-TiN. J Mater Sci: Mater Electron 29, 18105–18110 (2018). https://doi.org/10.1007/s10854-018-9921-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9921-3