Abstract

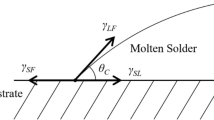

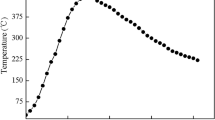

The relationships between solderability, free solder thickness and intermetallic thickness of Sn–0.7Cu–0.05Ni solder coatings on Cu substrate has been investigated. The annealing method was proposed to control free solder thickness by controlling the ratio of free solder and interfacial intermetallics (IMCs). The solderability of solder coating has investigated using a purpose-designed microwetting balance. The interfacial intermetallic microstructure was analysed and the thickness measured in the as-coated condition with aging process. Results indicate that the solderability is related to free solder thickness, where the increase of aging time and temperature thickness of the free solder is reduced by the interfacial intermetallic compound growth. Onwards, the different composition of germanium (Ge) was added into Sn–0.7Cu–0.05Ni as an antioxidant to control drossing of the molten solder. The effect on solderability of a Ge addition to the coating alloy was measured. These results may be used as a basis to obtain an optimum wettability of solder coating during soldering.

Similar content being viewed by others

References

S.H. Kim, J.M. Kim, S. Yoo, Y.B. Park, Effects of surface finishes and current stressing on the interfacial reaction characteristics of Sn-1.2Ag-0.7Cu-0.4In solder bumps. Curr. Appl. Phys. 13, 103–107 (2013)

K. Sweatman, Hot air solder leveling in the lead-free era, in Global SMT & Packaging, pp. 10–18 (2009)

J.-W. Yoon, S.-B. Jung, Effect of surface finish on interfacial reactions of Cu/Sn-Ag-Cu/Cu (ENIG) sandwich solder joints. J. Alloys Compd. 448, 177–184 (2008)

K. Sweatman, K. Howell, R. Coyle, R. Parker, G. Henshall, J. Smetana, E. Benedetto, W. Lui, R.S. Pandher, D. Daily, iNEMI Pb-free alloy characterization project report: part III–thermal fatigue results for low Ag alloys, in Proceeding of SMTAi (2012)

K. Nogita, Stabilisation of Cu6Sn5 by Ni in Sn-0.7Cu-0.05Ni lead-free solder alloys. Intermetallics 18, 145–149 (2010)

T. Ventura, C.M. Gourlay, K. Nogita, T. Nishimura, M. Rappaz, A.K. Dahle, The influence of 0-0.1 wt.% Ni on the microstructure and fluidity length of Sn0.7Cu-xNi. J. Electron. Mater. 37, 32–39 (2008)

R. Schueller, Creep corrosion on lead-free printed circuit boards in high sulfur environments. SMTA News J. Surf. Mount Technol. 21, 21 (2008)

M.F. Arenas, V.L. Acoff, Contact angle measurements of Sn-Ag and Sn-Cu lead-free solders on copper substrates. J. Electron. Mater. 33, 1452–1459 (2004)

J. Pstrus, P. Fima, T. Gancarz, Wetting of Cu and Al by Sn-Zn and Zn-Al eutectic alloys. J. Mater. Eng. Perform. 21, 606–613 (2012)

W. Li, Failure analysis on bad wetting of ENIG surface finish pads, in 2015 16th International Conference on Electronic Packaging Technology (ICEPT), IEEE, 2015, pp. 538–541

S. Zhang, S.-H. Kim, T.-W. Kim, Y.-S. Kim, K.-W. Paik, A study on the solder ball size and content effects of solder ACFs for flex-on-board assembly applications using ultrasonic bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 5, 9–14 (2015)

C.C. Tu, M.E. Natishan, Wettability test method for surface mount technology assessment. Solder. Surf. Mount Technol. 12, 10–15 (2000)

Q. Zeng, J. Guo, X. Gu, X. Zhao, X. Liu, Wetting behaviors and interfacial reaction between Sn-10Sb-5Cu high temperature lead-free solder and Cu substrate. J. Mater. Sci. Technol. 26, 156–162 (2010)

G. Kumar, K.N. Prabhu, Review of non-reactive and reactive wetting of liquids on surfaces. Adv. Colloid Interface Sci. 133, 61–89 (2007)

K.M. Martorano, M.A. Martorano, S.D. Brandi, Optimal conditions for the wetting balance test. J. Mater. Process. Technol. 209, 3089–3095 (2009)

T. Takemoto, M. Miyazaki, Effect of excess temperature above liquidus of lead-free solders on wetting time in a wetting balance test. Mater. Trans. 42, 745–750 (2001)

F.A.M. Sobri, M.A.A.M. Salleh, C.M. Ruzaidi, P. Narayanan, The effect of dipping time to the intermetallic compound and free solder thickness of Sn-Cu-Ni (SN100C) lead-free solder coating. Appl. Mech. Mater. 754, 493–497 (2015)

L. Mo, Z. Chen, F. Wu, C. Liu, Microstructural and mechanical analysis on Cu–Sn intermetallic micro-joints under isothermal condition. Intermetallics 66, 13–21 (2015)

D.Q. Yu, C.M.L. .Wu, C.M.T. Law, L. Wang, J.K.L. Lai, Intermetallic compounds growth between Sn-3.5 Ag lead-free solder and Cu substrate by dipping method. J. Alloys Compd. 392, 192–199 (2005)

M. Hasnine, B. Tolla, M. Karasawa, Effect of Ge addition on wettability, copper dissolution, microstructural and mechanical behavior of SnCu–Ge solder alloy. J. Mater. Sci.: Mater. Electron. 28, 16106–16119 (2017)

C. Yu, Y. Yang, P. Li, J. Chen, H. Lu, Suppression of Cu3Sn and Kirkendall voids at Cu/Sn-3.5 Ag solder joints by adding a small amount of Ge. J. Mater. Sci.: Mater. Electron. 23, 56–60 (2012)

A.T. Wu, M.H. Chen, C.N. Siao, The effects of solid-state aging on the intermetallic compounds of Sn-Ag-Bi-In solders on Cu substrates. J. Electron. Mater. 38, 252–256 (2009)

M.A.A.M. Salleh, S.D. McDonald, K. Nogita, Effects of Ni and TiO2 additions in as-reflowed and annealed Sn0.7Cu solders on Cu substrates. J. Mater. Process. Technol. 242, 235–245 (2017)

C. Yu, J. Chen, Z. Cheng, Y. Huang, J. Chen, J. Xu, H. Lu, Fine grained Cu film promoting Kirkendall voiding at Cu3Sn/Cu interface. J. Alloys Compd. 660, 80–84 (2016)

F. Cheng, Z. Ma, Y. Wang, Q. Zou, Creep behaviors of Sn0.7Cu0.1Co0.05Ni/Cu soldering joints. IEEE Trans. Compon. Packag. Manuf. Technol. 4, 2058–2065 (2014)

Acknowledgements

The authors gratefully acknowledge Nihon Superior (Grant No: 2016/10/0001) and fundamental research grant scheme (FRGS) (FRGS/1/2017/TK05/UNIMAP/02/7) (9003-00635) for the materials and finance support. Wetting balance test were conducted at Nihon Superior (M) Sdn Bhd, Ipoh, Malaysia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Rights and permissions

About this article

Cite this article

Ramli, M.I.I., Mohd Salleh, M.A.A., Mohd Sobri, F.A. et al. Relationship between free solder thickness to the solderability of Sn–0.7Cu–0.05Ni solder coating during soldering. J Mater Sci: Mater Electron 30, 3669–3677 (2019). https://doi.org/10.1007/s10854-018-00647-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-00647-5