Abstract

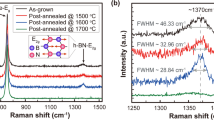

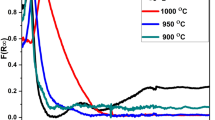

Hexagonal boron nitride (hBN) films were directly grown on c-plane Al2O3 substrates by low pressure thermal chemical vapor deposition (CVD) with single precursor i.e. borazane (NH3-BH3) without employing any extra catalysis. The growth temperature influence on the growth and properties of BN films were investigated. It was found that with a suitable source supply rate, the growth temperature could obviously influence the growth rate, chemical state, crystal structure and optical properties of BN films. High growth temperature depicts low thickness film grown, even there was no BN film deposited when the temperature was higher than or equal to 1400 °C. The B–N bonding type in all the deposited BN films were conformed as sp2 bonding, and films were evidenced to be amorphous BN (aBN) at lower growth temperature (i.e. less than 1350 °C) and hBN in turbostratic phase (tBN) between 1350 and 1400 °C. All the grown BN films on sapphire substrate showed good ultraviolet (UV) absorption edge near 210 nm, according to transmittance spectra. This work presents a feasible route towards combination of large-scale CVD-grown hBN film with traditional III-N compounds for applications in deep UV optoelectronic devices.

Similar content being viewed by others

References

K. Watanabe, T. Taniguchi, Int. J. Appl. Ceram. Technol. (2011). doi:10.1111/j.1744-7402.2011.02626.x

Y. Ji, C. Pan, M. Zhang, S. Long, X. Lian, F. Miao, F. Hui, Y. Shi, L. Larcher, E. Wu, M. Lanza, Appl. Phys. Lett. (2016). doi:10.1063/1.4939131

X. Li, J. Yin, J. Zhou, W. Guo, Nanotechnology. (2014). doi:10.1088/0957-4484/25/10/105701

I. Jo, M.T. Pettes, J. Kim, K. Watanabe, T. Taniguchi, Z. Yao, L. Shi, Nano Lett. (2013). doi:10.1021/nl304060g

L. Zheng, G. Yongji, Z. Wu, M. Lulu, Y. Jingjiang, J.C. Idrobo, J. Jung, A.H. MacDonald, R. Vajtai, L. Jun, P.M. Ajayan, Nat. Commun. (2013) doi:10.1038/ncomms3541

G. Cassabois, P. Valvin, B. Gil, Nat. Photonics (2016). doi:10.1038/nphoton.2015.277

S.K. Jang, J. Youn, Y.J. Song, S. Lee, Sci. Rep. (2016). doi:10.1038/srep30449

C.R. Dean, A.F. Young, I. Meric, C. Lee, L. Wang, S. Sorgenfrei, K. Watanabe, T. Taniguchi, P. Kim, K.L. Shepard, J. Hone, Nat. Nanotechnol. (2010). doi:10.1038/nnano.2010.172

S.H. Kang, G. Kim, Y.K. Kwon, Phys. Chem. Chem. Phys. (2015). doi:10.1039/c4cp05478d

J. Li, S. Majety, R. Dahal, W.P. Zhao, J.Y. Lin, H.X. Jiang, Appl. Phys. Lett. (2012). doi:10.1063/1.4764533

K. Watanabe, T. Taniguchi, H. Kanda, Nat. Mater. (2004). doi:10.1038/nmat1134

S. Majety, X.K. Cao, J. Li, R. Dahal, J.Y. Lin, H.X. Jiang, Appl. Phys. Lett. (2012). doi:10.1063/1.4742194

R. Dahal, J. Li, S. Majety, B.N. Pantha, X.K. Cao, J.Y. Lin, H.X. Jiang, Appl. Phys. Lett. (2011). doi:10.1063/1.3593958

H.X. Jiang, J.Y. Lin, Semicond. Sci. Technol. (2014). doi:10.1088/0268-1242/29/8/084003

K.K. Kim, A. Hsu, X. Jia, S.M. Kim, Y. Shi, M. Hofmann, D. Nezich, J.F. Rodriguez-Nieva, M. Dresselhaus, T. Palacios, J. Kong, Nano Lett. (2012). doi:10.1021/nl203249a

L. Song, L. Ci, H. Lu, P.B. Sorokin, C. Jin, J. Ni, A.G. Kvashnin, D.G. Kvashnin, J. Lou, B.I. Yakobson, P.M. Ajayan, Nano Lett. (2010). doi:10.1021/nl1022139

S. Park, J. Lee, H.S. Kim, J.-B. Park, K.H. Lee, S.A. Han, S. Hwang, S.-W. Kim, H.-J. Shin, ACS Nano (2015). doi:10.1021/nn505960b

M.S. Bresnehan, M.J. Hollander, M. Wetherington, K. Wang, T. Miyagi, G. Pastir, D.W. Snyder, J.J. Gengler, A.A. Voevodin, W.C. Mitchel, J.A. Robinson, J. Mater. Res. (2014). doi:10.1557/jmr.2013.323

R.Y. Tay, S.H. Tsang, M. Loeblein, W.L. Chow, G.C. Loh, J.W. Toh, S.L. Ang, E.H.T. Teo, Appl. Phys. Lett. (2015). doi:10.1063/1.4914474

B. Zhong, T. Zhang, X.X. Huang, G.W. Wen, J.W. Chen, C.J. Wang, Y.D. Huang, Mater. Lett. (2015). doi:10.1016/j.matlet.2015.03.059

T.C. Doan, S. Majety, S. Grenadier, J. Li, J.Y. Lin, H.X. Jiang, Nucl. Instrum. Methods Phys. Res. Sect. A (2015). doi:10.1016/j.nima.2015.02.045

Y. Kobayashi, K. Kumakura, T. Akasaka, T. Makimoto, Nature (2012). doi:10.1038/nature10970

N. Ouldhamadouche, A. Achour, K.A. Aissa, M. Islam, A. Ahmadpourian, A. Arman, M.A. Soussou, M. Chaker, L. Le Brizoual, M.A. Djouadi, Thin Solid Films (2017). doi:10.1016/j.tsf.2016.12.018

A. Ahmadpourian, C. Luna, A. Boochani, A. Arman, A. Achour, S. Rezaee, S. Naderi, Eur. Phys. J. Plus (2016). doi:10.1140/epjp/i2016-16381-2

A. Achour, R. Lucio-Porto, M. Chaker, A. Arman, A. Ahmadpourian, M.A. Soussou, M. Boujtita, L. Le Brizoual, M.A. Djouadi, T. Brousse, Electrochem. Commun. (2017). doi:10.1016/j.elecom.2017.02.011

R.Y. Tay, X. Wang, S.H. Tsang, G.C. Loh, R.S. Singh, H. Li, G. Mallick, E.H.T. Teo, J. Mater. Chem. C. (2014). doi:10.1039/c3tc32011a

S. Frueh, R. Kellett, C. Mallery, T. Molter, W.S. Willis, C. King’ondu, S.L. Suib, Inorg Chem. (2011). doi:10.1021/ic101020k

A.R. Jang, S. Hong, C. Hyun, S.I. Yoon, G. Kim, H.Y. Jeong, T.J. Shin, S.O. Park, K. Wong, S.K. Kwak, N. Park, K. Yu, E. Choi, A. Mishchenko, F. Withers, K.S. Novoselov, H. Lim, H.S. Shin, Nano Lett. (2016). doi:10.1021/acs.nanolett.6b01051

N.R. Glavin, M.L. Jespersen, M.H. Check, J. Hu, A.M. Hilton, T.S. Fisher, A.A. Voevodin, Thin Solid Films (2014). doi:10.1016/j.tsf.2014.07.059

M.R. Weismiller, S.Q. Wang, A. Chowdhury, S.T. Thynell, R.A. Yetter, Thermochim. Acta (2013). doi:10.1016/j.tca.2012.10.008

S. Reich, A. Ferrari, R. Arenal, A. Loiseau, I. Bello, J. Robertson, Phys. Rev. B (2005). doi:10.1103/PhysRevB.71.205201

Q. Weng, X. Wang, C. Zhi, Y. Bando, D. Golberg, ACS Nano (2013). doi:10.1021/nn305320v

Y. Kobayashi, T. Akasaka, J. Cryst. Growth (2008). doi:10.1016/j.jcrysgro.2008.07.010

N. Ghobadi, M. Ganji, C. Luna, A. Ahmadpourian, A. Arman, Opt. Quantum Electron. (2016). doi:10.1007/s11082-016-0742-4

N. Ghobadi, M. Ganji, C. Luna, A. Arman, A. Ahmadpourian, J. Mater. Sci. (2015). doi:10.1007/s10854-015-4093-x

Acknowledgements

This work was supported by National Key R&D Plan (Nos. 2016YFB0400600, 2016YFB0400601), National Science Foundation of China (Nos. 11675198, 61376046, 61574026), the Fundamental Research Funds for the Central Universities (Nos. DUT15LK15, DUT15RC(3)016, No. DUT16LK29), Liaoning Provincial Natural Science Foundation of China (Nos. 201602453, 201602176), China Postdoctoral Science Foundation Funded Project (No. 2016M591434), The Open Fund of the State Key Laboratory on Integrated Optoelectronics (No. IOSKL2015KF18, No.IOSKL2015KF22).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Y., Liang, H., Xia, X. et al. Growth temperature impact on film quality of hBN grown on Al2O3 using non-catalyzed borazane CVD. J Mater Sci: Mater Electron 28, 14341–14347 (2017). https://doi.org/10.1007/s10854-017-7294-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7294-7