Abstract

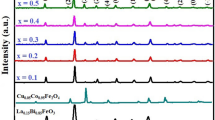

Sintering temperature is a key parameter that affects thermoelectric properties. In this study, a suitable temperature to synthesize thermoelectric properties of low-cost delafossite CuAl0.90Fe0.10O2 was investigated through the sintering of CuO, Al2O3 and Fe2O3 mixed powder at 1333, 1423 and 1473 K. The optimum sintering temperature is at 1333 K, where the single-phase CuAlO2 and the highest dimensionless figure of merit of 0.014 at the measured temperature of 873 K were observed. CuAlO2 with trace amounts of CuO, and CuAl2O4 and CuO were found at the sintering temperature of 1423 and 1473 K, respectively. The highest Seebeck coefficient and thermal conductivity was at the sintering temperature of 1473 K, with the maximum electrical conductivity and power factor at the measured temperature of 873 K of 5.7 Ω−1 cm−1 and 9.81 × 10−5 Wm−1 K−2, respectively.

Similar content being viewed by others

References

K. Park, K.Y. Ko, W.-S. Seo, J. Eur. Ceram. Soc. 25, 2219 (2005)

Y.-C. Liou, U.-R. Lee, J. Alloy. Compd. 467, 496 (2009)

Y.-C. Liou, L.-S. Chang, Y.-M. Lu, H.-C. Tsai, U.-R. Lee, Ceram. Int. 38, 3619 (2012)

K. Park, K.Y. Ko, J.K. Seong, S. Nahm, J. Eur. Ceram. Soc. 27, 3735 (2007)

K. Park, K.Y. Ko, W.-S. Seo, Mater. Sci. Eng. B 129, 1 (2006)

K. Park, K.Y. Ko, H.-C. Kwon, S. Nahm, J. Alloy. Compd. 437, 1 (2007)

S. Yanagiya, N. van Nong, J. Xu, N. Pryds, Materials 3, 318 (2010)

T. Stöcker, J. Exner, M. Schubert, M. Streibl, R. Moos, Materials 9, 227 (2016)

I. Terasaki, Y. Sasago, K. Uchinokura, Phys. Rev. B 56, R12685 (1997)

A.C. Masset, C. Michel, A. Maignan, M. Hervieu, O. Toulemonde, F. Studer, B. Raveau, J. Hejtmanek, Phys. Rev. B 62, 166 (2000)

M. Ohtaki, T. Tsubota, K. Eguchi, H. Arai, J. Appl. Phys. 79, 1816 (1996)

S. Ohta, H. Ohta, K. Koumoto, J. Ceram. Soc. Jpn. 114, 102 (2006)

I. Terasaki, Phys. B 328, 63 (2003)

K. Fujita, T. Mochida, K. Nakamura, J. Appl. Phys. 40, 4644 (2001)

Y. Ando, N. Miyamoto, K. Segawa, T. Kawata, I. Terasaki, Phys. Rev. B 60, 10580 (1999)

K. Koumoto, H. Koduka, W.-S. Seo, J. Mater. Chem. 11, 251 (2001)

K. Park, K.Y. Ko, W.-S. Seo, J. Eur. Ceram. Soc. 25, 2219 (2005)

Y.-C. Liou, L.-S. Chang, Y.-M. Lu, H.-C. Tsai, U.-R. Lee, Ceram. Int. 38, 3619 (2012)

N. Wongcharoen, T. Gaewdang, Phys. Procedia 2, 101 (2009)

K. Tonooka, K. Shimokawa, O. Nishimura, Thin Solid Films 441, 129 (2002)

W.D. Kingery, H.K. Bowen, D.R. Uhlmann, Introduction to Ceramics, 2nd edn. (John Wiley & Sons, New York, 1976), p. 519

Y. Lu, T. Nozue, N. Feng, K. Sagara, H. Yoshida, Y. Jin, J. Alloy. Compd. 650, 558 (2015)

E.A. Kirupa, A.M.E. Raj, C. Ravidhas, J. Mater. Sci. Mater. Electron. (2016). doi:10.1007/s10854-016-4930-6

X. Zhang, H. Hao, Q. He, X. Hu, Phys. B 394, 118 (2007)

H.F. Jiang, H.C. Lei, X.B. Zhu, G. Li, Z.R. Yang, W.H. Song, J.M. Dai, Y.P. Sun, Y.K. Fu, J. Alloys Compd. 487, 404 (2009)

S.-J. Liu, H. Wang, J.-W. Xu, M.-F. Ren, L. Yang, J.-H. Ju, J. Mater. Sci. Mater. Electron 22, 666 (2011)

L.D. Zhao, B.-P. Zhang, W.S. Liu, H.L. Zhang, J.-F. Li, J. Alloys Compd. 467, 91 (2009)

H.J. Goldsmid, Materials 2, 903 (2009)

C. Ruttanapun, A. Wichainchai, W. Prachamon, A. Yangthaisong, A. Charoenphakdee, T. Seetawan, J. Alloys Compd. 509, 4588 (2011)

P.A. Cox, Transition Metal Oxides An introduction to their Electronic Structure and Properties (Oxford University Press, Oxford, 1992), pp. 163–165

A.F. Ioffe, Semiconductor Thermoelements and Thermoelectric Cooling (Infosearch Limited, London, 1957)

N. Schwartz, W. Tantraporn, W.J. van der Grinten, Advanced Energy Conversion (Pergamon Press, Great Britain, 1963)

T. Nozaki, K. Hayashi, T. Kajitani, J. Electron. Mater. 39, 1798 (2010)

Acknowledgments

The authors gratefully acknowledge financial support from the Faculty of Science, King Mongkut’s Institute of Technology Ladkrabang. We also appreciate the access to SEM imaging at the College of Advanced Manufacturing Innovation, King Mongkut’s Institute of Technology Ladkrabang and the DC four-terminal method at the Faculty of Science and Technology, Rajamangala University of Technology Suvarnabhumi.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siriwongrungson, V., Sakulkalavek, A. & Sakdanuphab, R. Optimum sintering temperature for thermoelectric properties of low-cost CuAl0.90Fe0.10O2 material. J Mater Sci: Mater Electron 27, 11102–11109 (2016). https://doi.org/10.1007/s10854-016-5227-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5227-5