Abstract

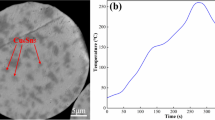

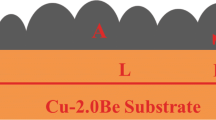

This study investigated the microstructure and grain orientation of Ni(V)/SAC396/OSP Cu and Ni(V)/SAC105/OSP Cu solder joints during thermal cycling test (TCT). In general, adjusting Ag content in solders influenced the performance of thermal cycling (TC). Nevertheless, it is still crucial to find the optimal condition of Ag and related mechanisms of crack formation during TCT. This study applied FE-SEM to observe the crack propagation and the precipitation of Sn–Ag IMCs in the solders. Moreover, FE-EPMA and EBSD were used to detect the elemental distribution and grain orientation near the cracks, respectively. The locations of crack initiation are strongly related to the CTE mismatch between Si chip and solder alloy. Besides, the large number of Ag3Sn precipitations in the joint with high Ag content efficiently hinder the crack propagation due to the effects of precipitation hardening. It is revealed that the Ni(V)/SAC396/OSP Cu exhibits good thermal stability during thermal cycle test.

Similar content being viewed by others

References

T. Luo, Z. Chen, A. Hu, M. Li, Mater. Sci. Eng., A 556, 885–890 (2012)

S. Ahat, M. Sheng, L. Luo, J. Electron. Mater. 30, 1317–1322 (2001)

H.T. Lee, Y.H. Lee, Mater. Sci. Eng., A 419, 172–180 (2006)

C.M. Chuang, P.C. Shih, K.L. Lin, J. Electron. Mater. 33, 1–6 (2004)

I. Shohji, T. Yoshida, T. Takahashi, S. Hioki, Mater. Sci. Eng., A 366, 50–55 (2004)

C.F. Tseng, C.J. Lee, J.G. Duh, Mater. Sci. Eng., A 574, 60–67 (2013)

C. Andersson, P.E. Tegehall, D.R. Andersson, G. Wetter, J. Liu, Fellow. IEEE. 31, 331–344 (2008)

Y. Kwon, H. Bang, S. Joo, H. Bang, Microelectron. Reliab. 55, 442–447 (2015)

Y. Sun, J. Liang, Z.H. Xu, G. Wang, X. Li, J. Electron. Mater. 38, 400–409 (2009)

B. Arfaei, S.M. Shirazi, S. Joshi, M. Anselm, P. Borgesen, E. Cotts, J. Wilcox, R. Coyle, IEEE Electron (Compon. & Tech, Conf, 2013)

J. Han, H. Chen, M. Li, Acta Metall. Sin. 25, 214–224 (2012)

B. Zhou, Q. Zhou, Thomas R. Bieler, T.K. Lee. J. Electron. Mater. 44, 895–908 (2015)

M. Amagai, M. Watanabe, M. Omiya, K. Kishimoto, T. Shibuya, Microelectron. Reliab. 42, 951–966 (2002)

F.X. Che, W.H. Zhu, Edith S.W. Pohb, X.W. Zhanga, X.R. Zhang. J. Alloys Compd. 507, 215–224 (2010)

S. Terashima, Y. Kariya, T. Hosoi, M. Tanaka, J. Electron. Mater. 32, 1527–1533 (2003)

L. Yin, L. Wentlent, L. Yang, B. Arfaei, A. Oasaimeh, P. Borgesen, J. Electron. Mater. 41, 241–252 (2012)

J. Hokka, T.T. Mattila, H. Xu, M. Paulasto-kröckel. J. Electron. Mater. 42, 963–972 (2013)

R. Abbaschian, L. Abbaschian, R.E. Reed-Hill, Physical Metallurgy Principles, 4th edn. (Cengage Learning, Stamford, 2010), pp. 515–518

H. Chen, J. Han, J. Li, M. Li, Microelectron. Reliab. 52, 1112–1120 (2012)

S. Park, R. Dhakal, L. Lehman, E. Cotts, Acta Mater. 55, 3253 (2007)

M.A. Matin, W.P. Vellinga, M.G.D. Geers, Mater. Sci. Eng., A 73, 445–446 (2007)

T.T. Mattila, H. Xu, O. Ratia, M. Paulasto-Kröckel, IEEE 2010 Proceedings 60th Electron Component and Tech nical Conf erence (ECTC), Las Vegas, NV, 581, (2010), pp. 1–4

T.K. Lee, K.C. Liu, T.R. Bieler, J. Electron. Mater. 38, 2685 (2009)

T.R. Bieler, H. Jiang, L.P. Lehman, T. Kirkpatrick, E.J. Cotts, B. Nandagopal, IEEE Trans. Compon. Packag. Technol. 31, 370 (2008)

H. Chen, J. Li, M. Li, J. Alloys Compd. 540, 32–35 (2012)

H.F. Hsu, S.W. Chen, Acta Mater. 52, 2541–2547 (2004)

M. Maleki, J. Cugnoni, J. Botsis, Acta Mater. 61, 103–114 (2013)

Acknowledgments

Financial support from the Ministry of Science and Technology (MOST), Taiwan, under the Contract No. NSC-103-2221-E-007-020-MY3 and the technical support from Industrial Technology Research Institute, Electronics and Optoelectronics Research Laboratories, Advanced Package Technology Division: 3D Stacking and Reliability Technology Department are much appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, C.J., Chen, WY., Chou, TT. et al. The investigation of interfacial and crystallographic observation in the Ni(V)/SAC/OSP Cu solder joints with high and low silver content during thermal cycling test. J Mater Sci: Mater Electron 26, 10055–10061 (2015). https://doi.org/10.1007/s10854-015-3687-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3687-7