Abstract

The effect of ultrasonic wave (USW) and electric field (E) on the solderability of Sn2.5Ag0.7Cu0.1RE/Cu was investigated. Compared with the sample soldered conventionally, the solder joint obtained with USW and E assisted resulted in significant changes in the microstructure. The thickness and roughness of the interfacial Cu6Sn5 intermetallic compound (IMC) layer decreased by 39 and 56 %, respectively. The shear strength of the solder joint increased by 68 %, and the fracture mechanism of the solder joint transformed from brittle fracture occurred in the interfacial IMC layer to ductile fracture occurred in the solder alloy. The results reveal that reliable soldering of Sn2.5Ag0.7Cu0.1RE/Cu can be achieved with USW and E assisted, despite of low-halogen flux.

Similar content being viewed by others

References

L. Zhang, S.B. Xue, L.L. Gao et al., Effects of rare earths on properties and microstructures of lead-free solder alloys. J Mater Sci Mater Electron 20, 685–694 (2009)

J.W.R. Teo, Y.F. Sun, Spalling behavior of interfacial intermetallic compounds in Pb-free solder joints subjected to temperature cycling loading. Acta Mater 56, 242–249 (2008)

Y.L. Wang, K.K. Zhang, C.Y. Li et al., The morphology and evolution of Cu6Sn5 at the interface of Sn-2.5Ag-0.7Cu-0.1RE/Cu solder joint during the isothermal aging. Mater Sci Forum 704–705, 685–689 (2012)

P. Liu, P. Yao, J. Liu, Evolutions of the interface and shear strength between SnAgCu-xNi solder and Cu substrate during isothermal aging at 150 °C. J Alloy Compd 486, 474–479 (2009)

K.K. Zhang, C.Y. Li, R.F. Qiu et al., Effect of Ni on the growing of intermetallic compound in the interface of Sn2.5Ag0.7Cu0.1RE/Cu solder joint during aging. Mater Sci Technol 28, 760–765 (2012)

D.M. Jacobson, G. Humpston, Fluxles soldering. Int Mater Rev 51(5), 313–328 (2006)

M. Naka, K.M. Hafez, Applying of ultrasonic waves on brazing of alumina to copper using Zn-Al filler alloy. J Mater Sci 38, 3491–3494 (2003)

H.E. Mohamed, M. Khalid, N.M. Hafez et al., Ultrasonic brazing of aluminum to stainless steel. Trans JWRI 32(1), 143–146 (2003)

J.C. Yan, X.L. Sun, Ultrasonic vibration assisted brazing technology. Weld Join 3, 6–13 (2009)

Z.W. Xu, L. Ma, J.C. Yan et al., Wetting and oxidation during ultrasonic soldering of an alumina reinforced aluminum-copper-magnesium (2024A1) matrix composite. Composites 43, 407–414 (2012)

R.K. Chinnam, C. Fauteux, J. Neuenschwander et al., Evolution of the microstructure of Sn-Ag-Cu solder joints exposed to ultrasonic waves during solidification. Acta Mater 59, 1474–1481 (2011)

S. Matsuoka, H. Imai, Direct welding of different metals used ultrasonic vibration. J Mater Process Technol 209, 954–960 (2009)

K. Jung, H. Conrad, Effect of an electric field on microstructure coarsening in 60Sn40Pb solder joints. Mater Sci Eng A 356, 8–16 (2003)

D.S. Li, Z.K. Fan, Effects of chromium and electrical field on wettability between copper and tungsten. Rare Metal Mater Eng 36(6), 1008–1011 (2007)

K.K. Zhang, N. Ma, Z.L. Zhang et al., Electro-superplastic compression behavior of 1.6 % C ultrahigh carbon steel and its electro-superplastic welding to 40Cr steel. Trans Mater Heat Treat 31(9), 28–32 (2010)

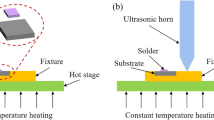

Zhang KK, Zhao K, Shi HX, Hu WH (2013) A kind of ultrasonic vibration and electric field assisted soldering equipment, CN Patent 201320121855.0, published 31 July 2013

D.Q. Yu, L. Wang, The growth and roughness evolution of intermetallic compounds of Sn-Ag-Cu/Cu interface during soldering reaction. J Alloy Compd 458, 542–547 (2008)

J.C. Gong, C.Q. Liu, P.P. Conway et al., Evolution of CuSn intermetallics between molten SnAgCu solder and Cu substrate. Acta Mater 56, 4291–4297 (2008)

M.D. Luque de Castro, F. Priego-Capote, Ultrasound-assisted crystallization (sonocrystallization). Ultrason Sonochem 14, 717–724 (2007)

N. Karunakaran, V. Balasubrmanian, Effect of pulsed current on temperature distribution, weld bead profiles and characteristics of gas tungsten arc welded aluminum alloy joints. Trans Nonferrous Metals Soc China 21, 278–286 (2011)

M.Y. Li, C.Q. Wang, H.S. Bang et al., Development of a flux-less soldering method by ultrasonic modulated laser. J Mater Process Technol 168, 303–307 (2005)

Acknowledgments

The work was supported by the Natural Science Foundation of China (50774029) and (U1204520), Science and Technology Innovation Team of Henan Province, and Science and Technology Innovation Team Support Plan of Henan University (13IRTSTHN003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, K., Zhang, X., Qiu, R. et al. The combined effects of ultrasonic wave and electric field on the microstructure and properties of Sn2.5Ag0.7Cu0.1RE/Cu soldered joints. J Mater Sci: Mater Electron 25, 1681–1686 (2014). https://doi.org/10.1007/s10854-014-1783-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-1783-8