Abstract

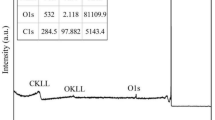

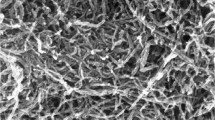

A novel Sn–Bi composite solder reinforced by nanosized graphite was studied. Effect of nanosized graphite content on spreadability was studied by spreading test. Microstructure of Sn–Bi solder and Sn–Bi composite solder was observed by scanning electron microscope. The tensile test and creep test for Sn–Bi solder and Sn–Bi composite solder joints were conducted in a micro-mechanical test system. The results show that the addition of nanosized graphite is harmful to the spreadability of Sn–Bi solder. The microstructure of Sn–Bi composite solder is refined gradually with the content of graphite increased. The ultimate tensile strength of Sn–Bi composite solders joints is reduced with the addition of nanosized graphite and the ultimate tensile strength of Sn–Bi + 0.07 wt% solder joint is almost unchanged compared with Sn–Bi solder joint. There is a great improvement in elongation of Sn–Bi + 0.07 wt% graphite solder joint. Furthermore, Sn–Bi + 0.07 wt% composite solder has a better creep performance compared with Sn–Bi solder.

Similar content being viewed by others

References

F. Tai, F. Guo, Z.D. Xia et al., Processing and creep properties of Sn-Cu composite solders with small amounts of nanosized Ag reinforcement additions. J. Electron. Mater. 34(11), 1357–1362 (2005)

Y.W. Shi, J.P. Liu, Y.F. Yan et al., Creep properties of composite solders reinforced with nano- and microsized particles. J. Electron. Mater. 37(4), 507–514 (2008)

Y.W. Shi, Y.F. Yan, J.P. Liu et al., Constitutive relations for creep in a SnCu-based composite solder reinforced with Ag particles. J. Electron. Mater. 38(9), 1866–1873 (2009)

F. Tai, F. Guo, M.T. Han et al., Creep and thermomechanical fatigue properties of in situ Cu6Sn5 reinforced lead-free composite solder. Mater. Sci. Eng., A 527, 3335–3342 (2010)

J.C. Leong, L.C. Tsao et al., Effect of nano-TiO2 addition on the microstructure and bonding strengths of Sn3.5Ag0.5Cu composite solder BGA packages with immersion Sn surface finish. J. Mater. Sci.: Mater. Electron. 22, 1443–1449 (2011)

L.C. Tsao, An investigation of microstructure and mechanical properties of novel Sn3.5Ag0.5Cu–xTiO2 composite solders as functions of alloy composition andcooling rate. Mater Sci Eng A529, 41–48 (2011)

L.C. Tsao, C.H. Huang, C.H. Chung et al., Influence of TiO2 nanoparticles addition on the microstructural and mechanical properties of Sn0.7Cu nano-composite solder. Mater Sci Eng A545, 194–200 (2012)

A.R. Geranmayeh, R. Mahmudi, M. Kangooie, High-temperature shear strength of lead-free Sn-Sb-Ag/Al2O3 composite solder. Mater Sci Eng A528, 3967–3972 (2011)

Gain AK, Fouzder T, Chan YC et al. (2011) Microstructure, kinetic analysis and hardness of Sn-Ag-Cu-1 wt% nano-ZrO2composite solder on OSP-Cu pads. Journal of Alloys and Compounds 509(7):3319–3325

S.M.L. Nai, J. Wei, M. Gupta, Lead-free solder reinforced with multiwalled carbon nanotubes. J. Electron. Mater. 35(7), 1518–1522 (2006)

S.M.L. Nai, J. Wei, M. Gupta, Effect of carbon nanotubes on the shear strength and electrical resistivity of a lead-free solder. J. Electron. Mater. 37(4), 515–522 (2008)

S.M.L. Nai, J. Wei, M. Gupta, Using carbon nanotubes to enhance creep performance of lead free solder. Mater. Sci. Technol. 24(4), 443–448 (2008)

S.M.L. Nai, J. Wei, M. Gupta, Interfacial intermetallic growth and shear strength of lead-free composite solder joints. J. Alloy. Compd. 473, 100–106 (2009)

Y.D. Han, S.M.L. Nai, H.Y. Jing et al., Development of a Sn–Ag–Cu solder reinforced with Ni-coated carbon nanotubes. J. Mater. Sci.: Mater. Electron. 22, 315–322 (2011)

Y.D. Han, H.Y. Jing, S.M.L. Nai et al., Creep mitigation in Sn–Ag–Cu composite solder with Ni-coated carbon nanotubes. J. Mater. Sci.: Mater. Electron. 23, 1108–1115 (2012)

R.H. Zhang, G.C. Xu, X.T. Wang et al., Electromigration in Sn-Bi Modified with Polyhedral Oligomeric Silsesquioxane. J. Electron. Mater. 39(12), 2513–2521 (2010)

J. Sun, G.C. Xu, Z.D. Xia et al., Effects of electromigration on resistance changes in eutectic SnBi solder joints. J. Mater. Sci. 46, 3544–3549 (2011)

J. Sun, C.F. Peng, H.G. Yin et al., Influence of minor POSS molecules additions on the microstructure and hardness of Sn3Ag0.5Cu–xPOSS composite solders. J. Mater. Sci.: Mater. Electron. 23, 1640–1646 (2012)

Li Yang, Effects of Ag particles content on properties of Sn0.7Cu solder. J. Mater. Sci.: Mater. Electron. 24, 1405–1409 (2013)

Yoshihiko Kanda, Yoshiharu Kariya, Evaluation of creep properties for Sn–Ag–Cu micro solder joint by multi-temperature stress relaxation test. Microelectronic Realiability 52, 1435–1440 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Du, C., Dai, J. et al. Effect of nanosized graphite on properties of Sn–Bi solder. J Mater Sci: Mater Electron 24, 4180–4185 (2013). https://doi.org/10.1007/s10854-013-1380-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1380-2